Electromagnetic harmonic oscillating tooth transmission torque characteristic analysis system and analysis method thereof

A technology of movable tooth transmission and torque characteristics, applied in the field of transmission, can solve the problems of measurement effect error and optimization, and achieve the effects of accurate measurement results, simple structure, and accurate force analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following is further described in detail through specific implementation methods:

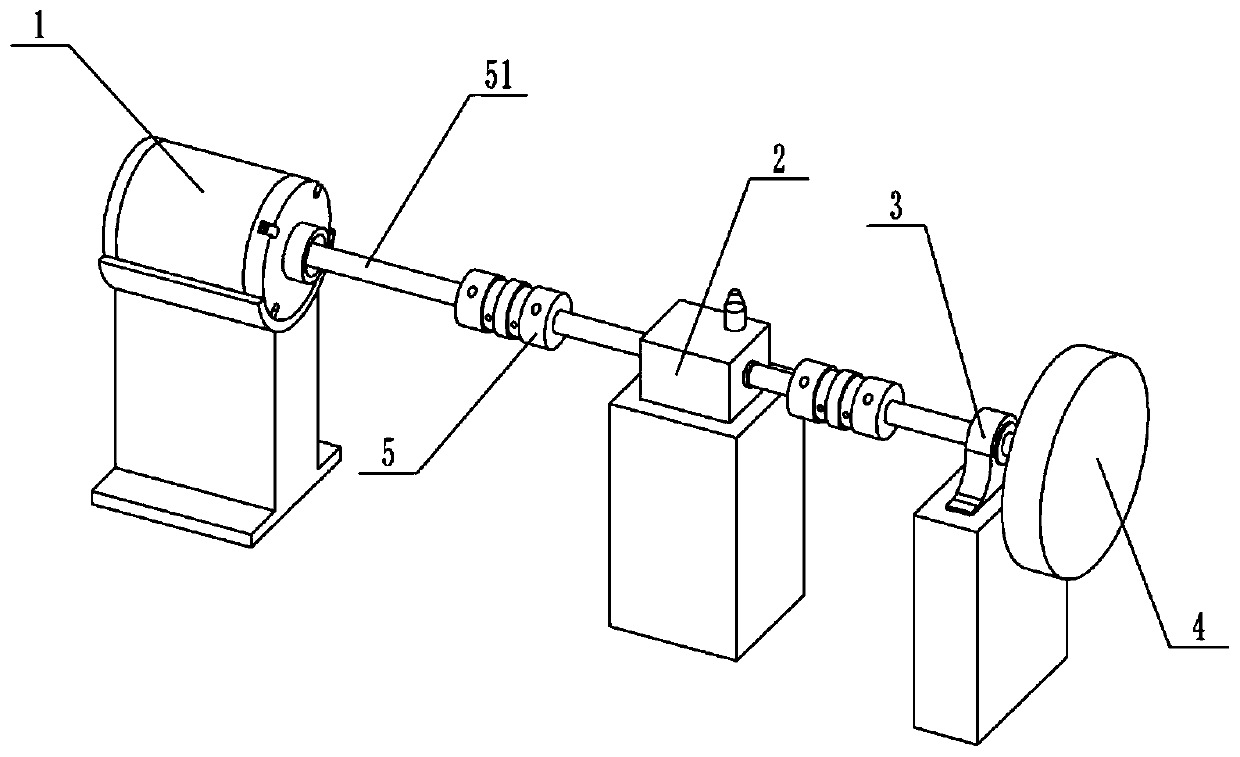

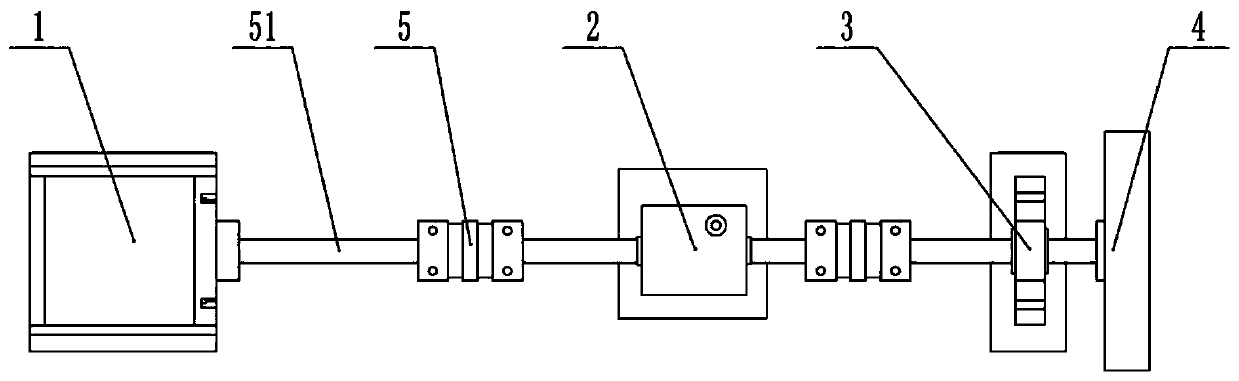

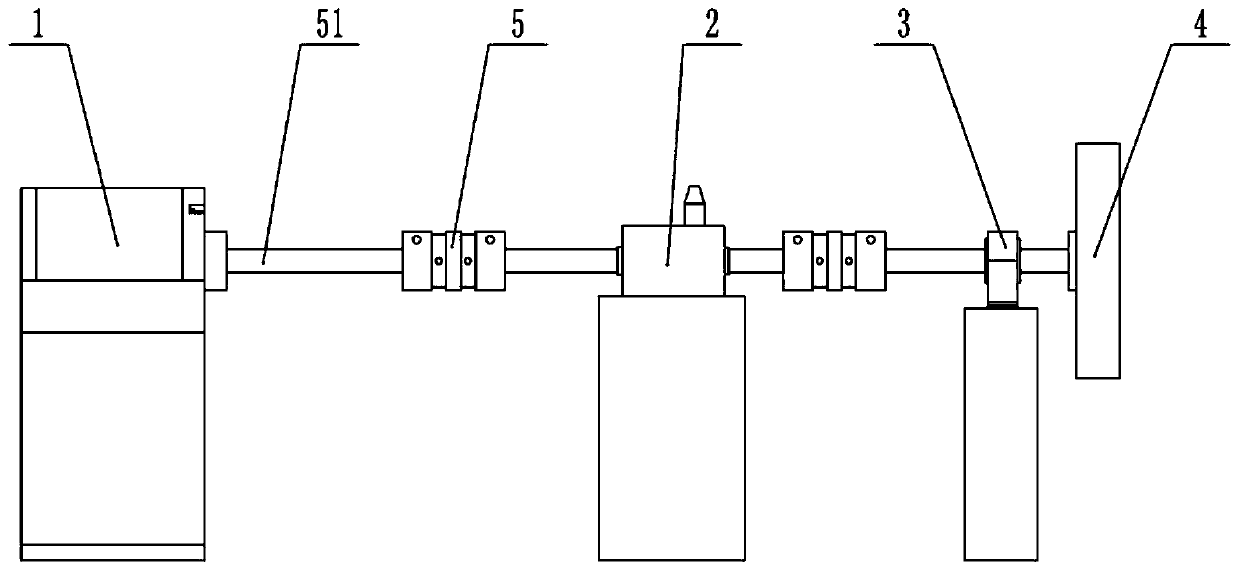

[0036] The reference signs in the accompanying drawings of the specification include: electromagnetic harmonic movable tooth transmission device 1, torque tester 2, support 3, flywheel 4, coupling 5, housing 10, end cover 21, lighting lamp 22, bump 23, video camera 24, electromagnetic winding 31, flex spline 32, center wheel 41, movable tooth 42, movable gear frame 43, output shaft 51, bearing 52.

[0037] XOY is the fixed coordinate system of the system;

[0038] X'OY' and X"OY" are the connected coordinate system of the rotating magnetic field and the movable rack respectively;

[0039] O is the center of rotation of the shock wave and the movable rack;

[0040] o i is the center of the movable tooth;

[0041] The force of the shock wave on the movable tooth is F 1i ;

[0042] The force that the movable gear rack exerts on the movable tooth is F 2i ;

[0043] The force F ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com