Method for on-line fault diagnosis of vibration threading and its equipment

A fault diagnosis and tapping technology, applied in the field of machining, can solve the problems of poor tap working condition, different cutting speed and vibration frequency, tap breakage, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

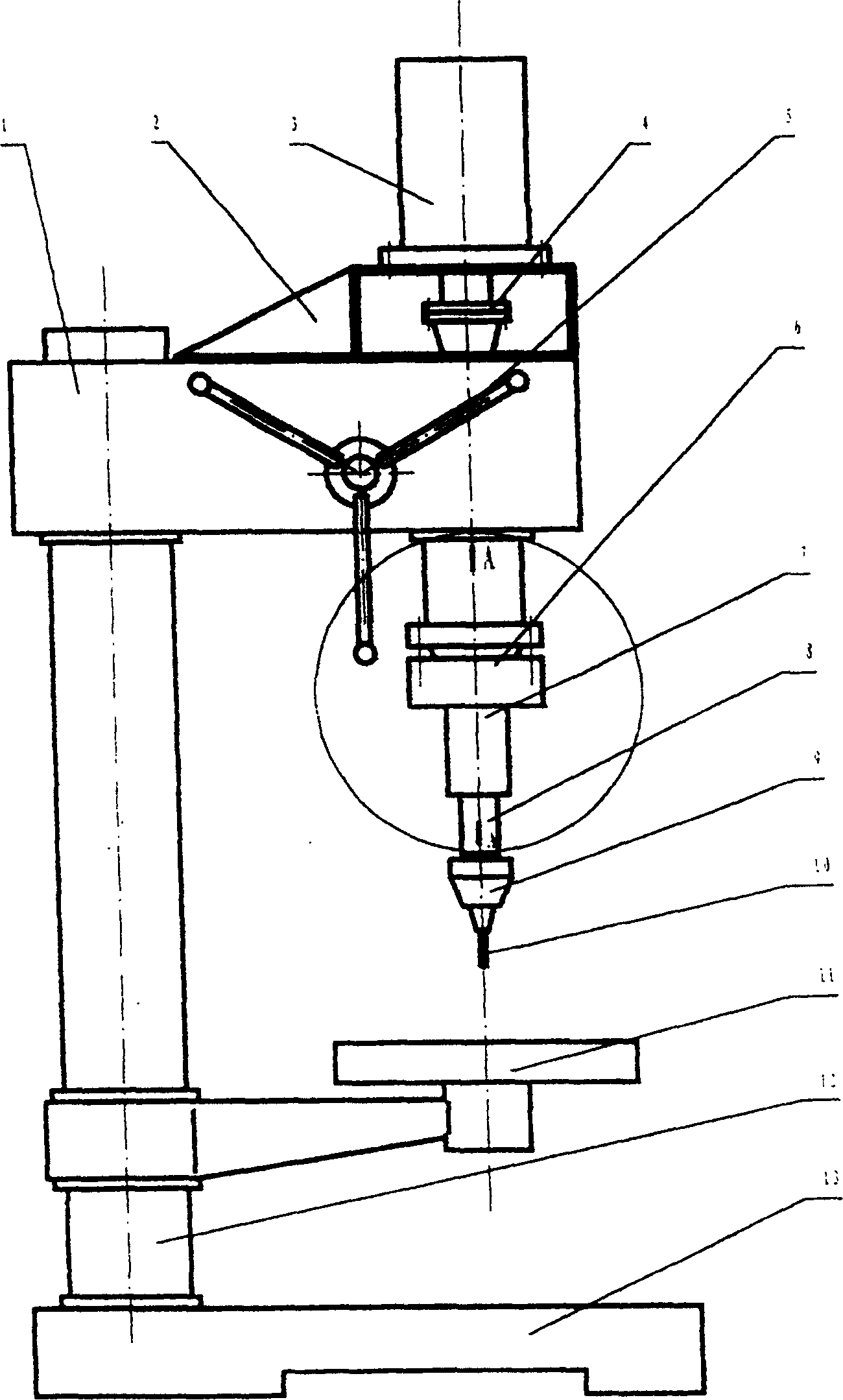

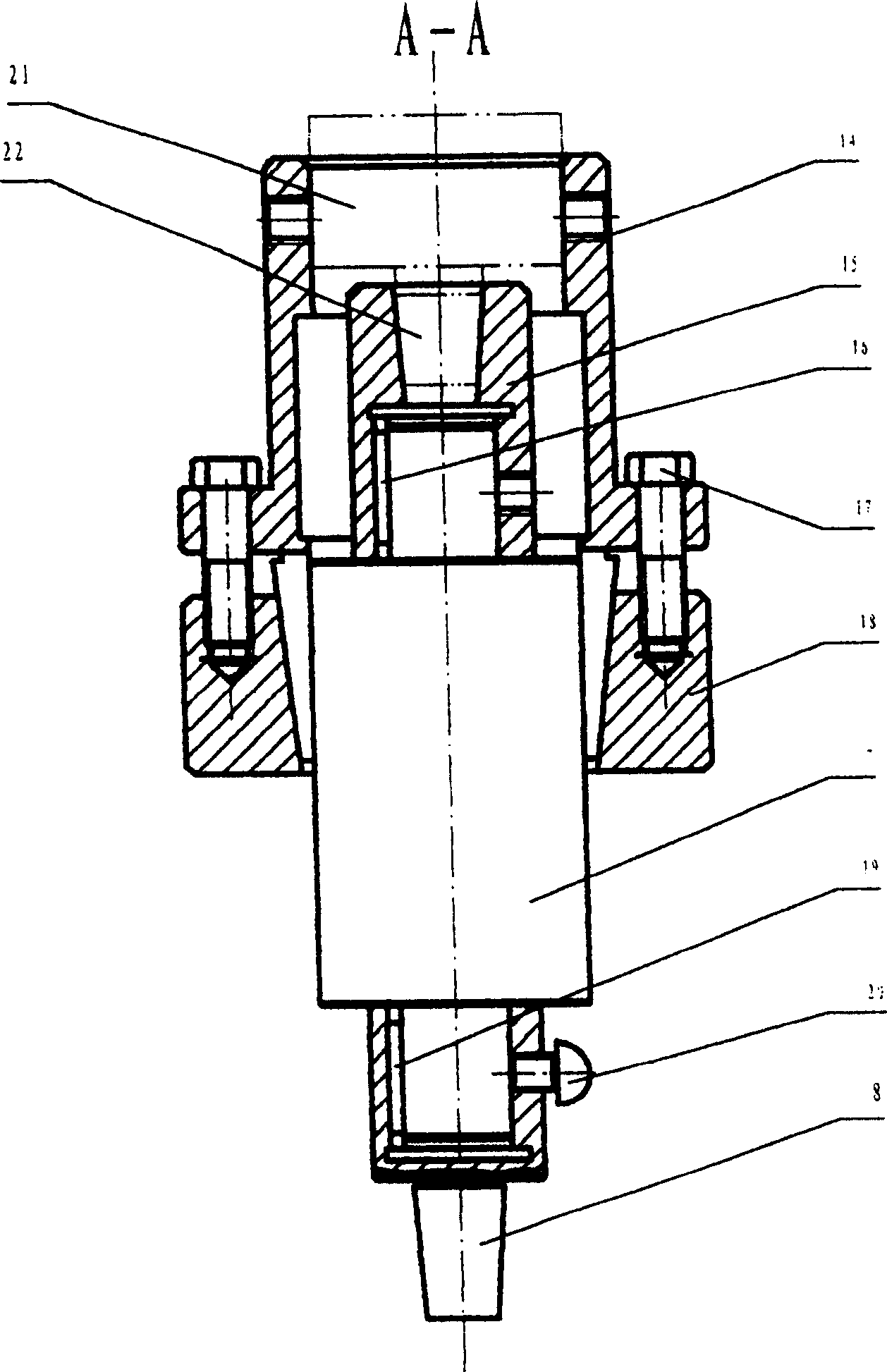

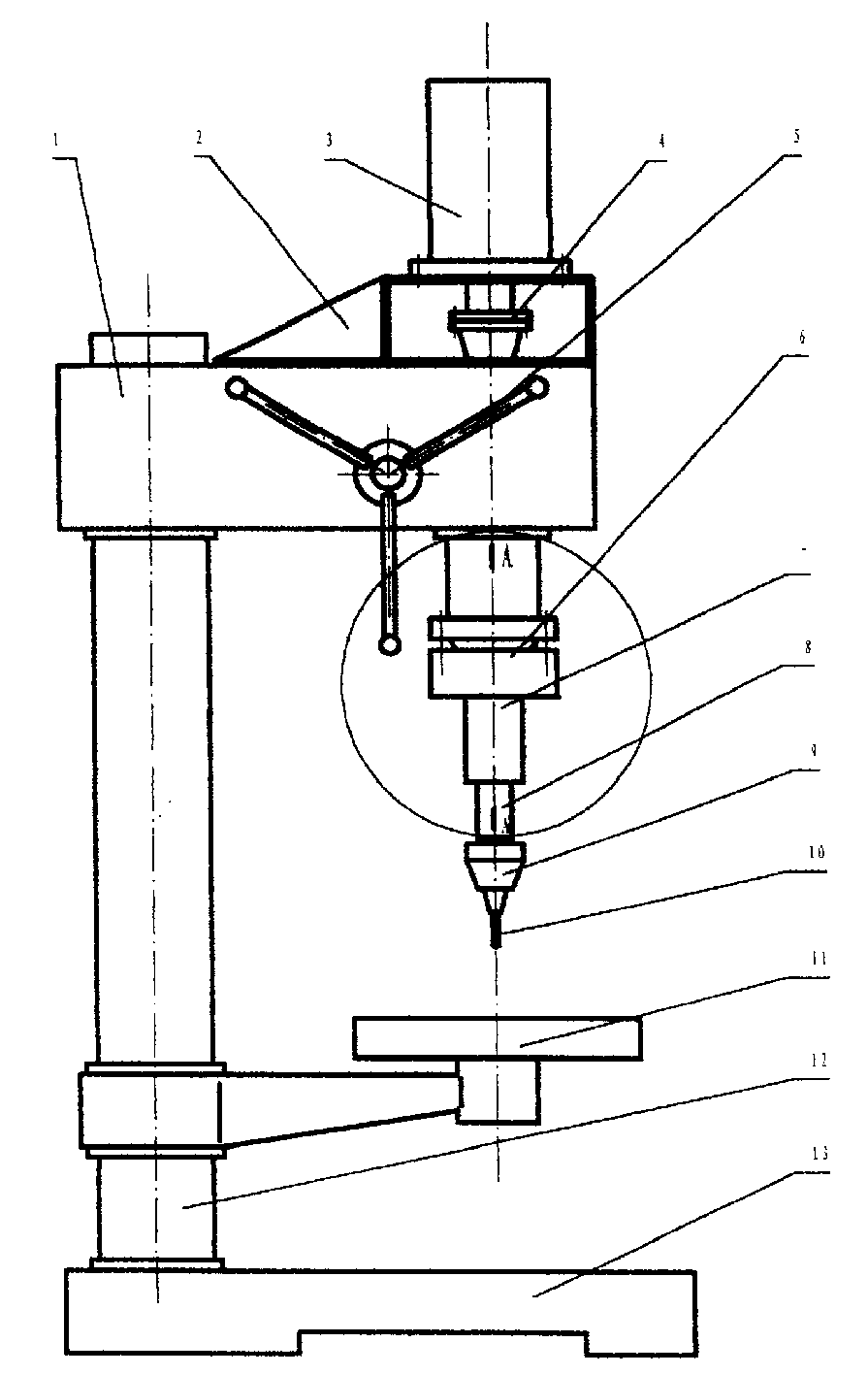

[0030] Concrete embodiment and accompanying drawing are described in detail as follows:

[0031] Such as Figure 1 As shown, the power of the whole vibratory tapping system is provided by the stepping motor (3), and the stepping motor (3) is fixed on the stepping motor fixing frame (2) through its flange plate, and the stepping motor fixing frame (2) The bottom plate is fixed on the top plane of the bed (1) of the machine tool; the bed (1) is set on the column (12) of the vibration tapping machine, and the position of the bed of the machine tool can be adjusted up and down and locked to fix the bed; the machine bed of the tapping machine The column (12) is fixed on the vibratory tapping machine base (13); the rotary disc workbench (11) is fixed on the machine column (12) and is below the tap (10). The feed mechanism of this vibratory tapping machine is a common feed mechanism of an ordinary tapping machine, such as a rack and pinion mechanism. The rack mechanism drives the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com