Residual torque analyzer

a technology of resistive torque and analyzer, which is applied in the direction of force/torque/work measurement apparatus, screws, instruments, etc., can solve the problems of under-torqued fasteners that can snap or strip their threads, shorten the extension of a tightening tool, and may vibrate or work loos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

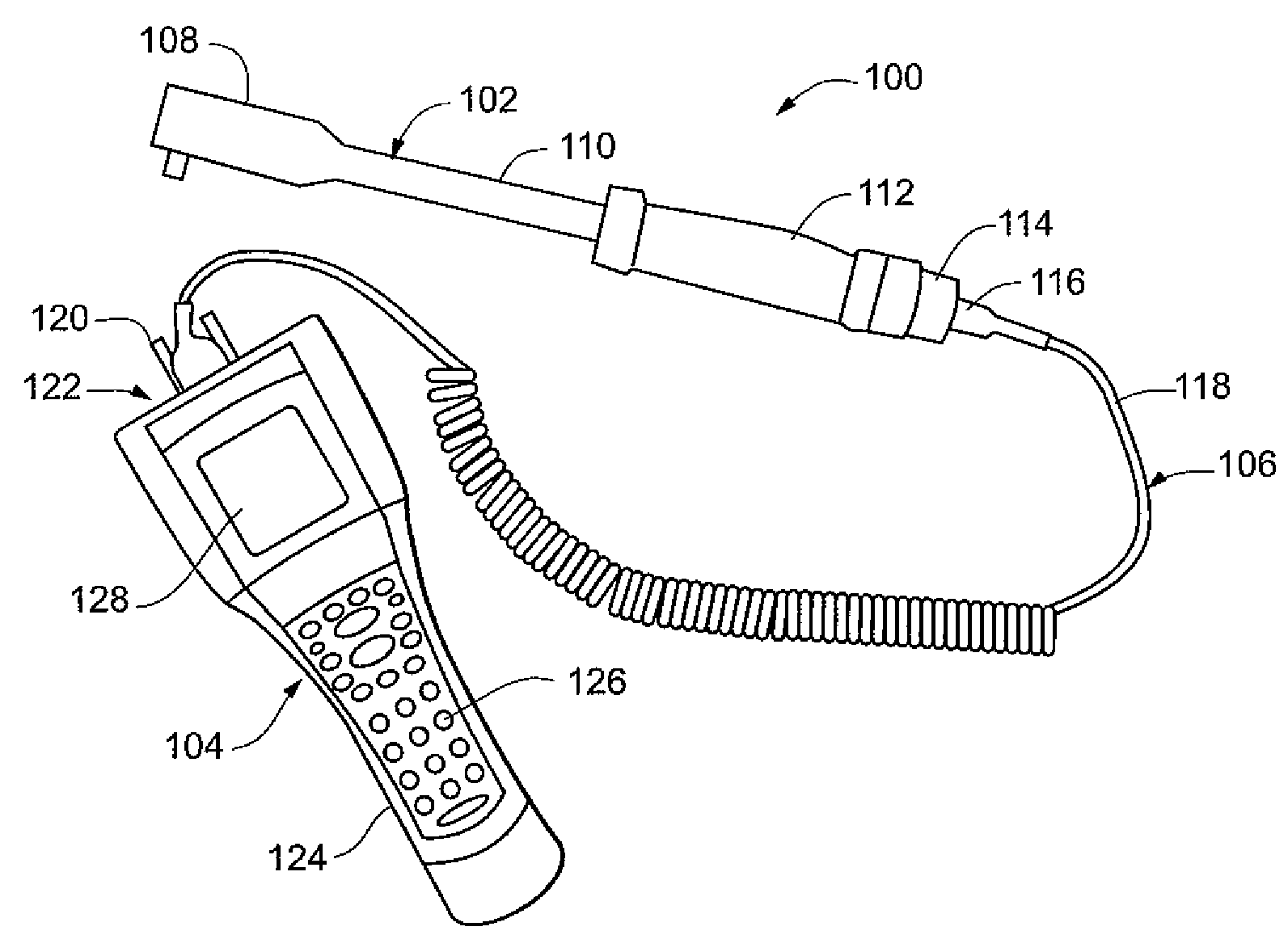

[0050]Referring to FIG. 6, in one embodiment, the present invention is a torque analyzer 100 that includes torque-angle wrench 102, data collector-analyzer (DCA) 104, and communication cable 106. Although depicted as separate components, it will be appreciated that in some embodiments, torque-angle wrench 102 and DCA 104 may be integrated to form torque analyzer 100, thereby eliminating the need for communication cable 106.

[0051]Referring to FIGS. 6-8, torque-angle wrench 102 includes head assembly 108, shaft 110, handle 112, and connector 114. In one embodiment, head assembly 108 includes circuit board assembly 132, cover plate 140, screws 142, torque transducer 134, and socket retainer 146. Head assembly 108 defines an electronics cavity 130 that houses circuit board assembly 132. As will be discussed in further detail below, circuit board assembly 132 includes gyroscope 136 and indicating LED 138. Cover plate 140 covers an opening of cavity 130 to enclose circuit board assembly 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com