Repeated bending testing equipment under constant load and method

A technology of repeated bending and constant load, applied in the field of detection, can solve problems such as mutual interference, failure to achieve constant load repeated bending performance test, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

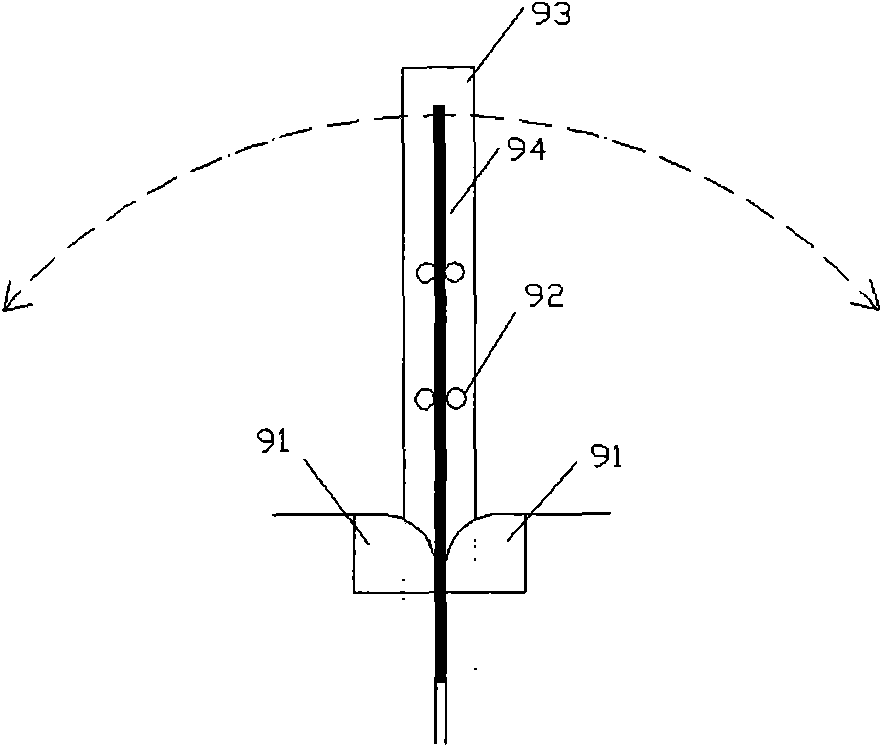

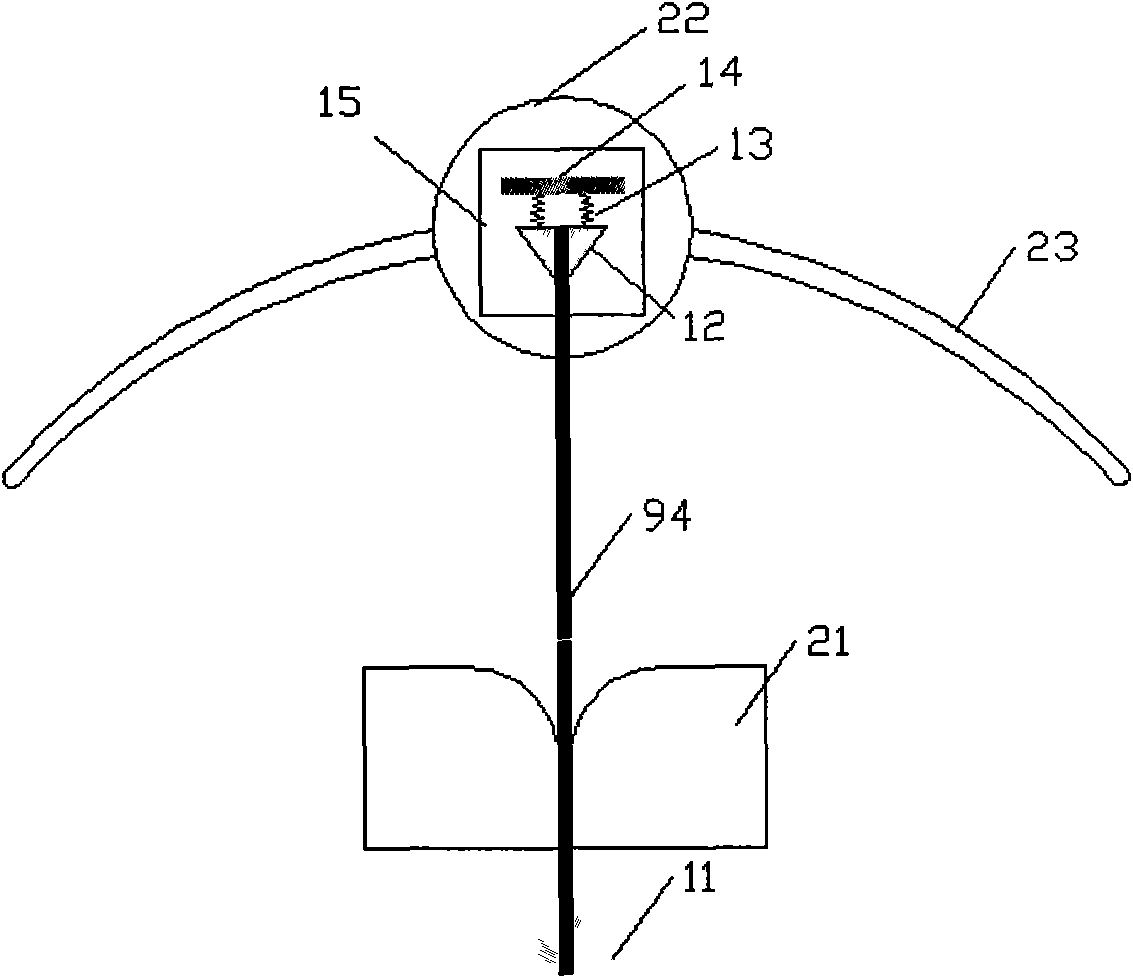

[0032] Attached below figure 2 To describe further:

[0033] The repeated bending equipment under constant load includes two parts: stretching system 1 and bending system 2.

[0034] The stretching system includes a first clamping device 11 , a second clamping device 12 , an elastic device 13 , a fixing device 14 , and a stretching loading table 15 .

[0035] The first clamping device 11 and the second clamping device 12 are respectively fixed at both ends of the sample 94 . The first clamping device 11 is fixed on the base body and remains stationary during the test. The second clamping device 12 is connected with the fixing device 14 through the elastic device 13 . Within the test load range of the elastic device 13, the relationship between tension and elongation satisfies Hooke's law. The fixing device 14 is installed on the tensile loading platform 15, and the fixing device 14 can move along the length direction of the sample 94 on the tensile loading platform 15, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com