Gluing fixed support for tensile property tests on fiber multifilaments and fiber multifilament sample preparing method

A fiber multifilament and tensile property technology, applied in the preparation of test samples, measuring devices, strength characteristics, etc., can solve the problem of inability to adjust and control the size of the tension, achieve reliable data, ensure the success rate, and improve the pass rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

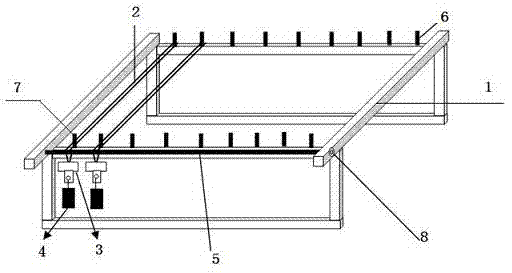

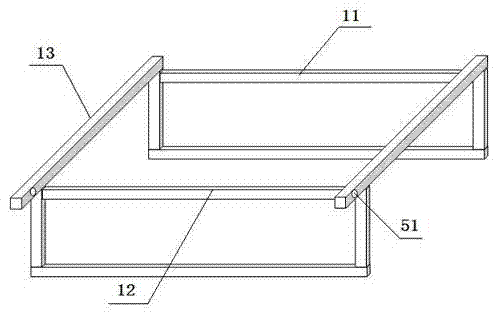

[0026] Combine below Figure 1 to Figure 4 , the present invention is further described:

[0027] Such as figure 1 As shown, a glued fixing frame for fiber multifilament tensile performance testing includes a fixed frame body 1, one end of the fixed frame body 1 is provided with a plurality of fixed round rods 6, and the other end of the fixed frame body 1 is also correspondingly arranged There are the same number of separating round rods 7, and each dipped fiber multifilament 2 forms two parts parallel to each other by hanging on a fixed round rod 6, and the two ends of the dipped fiber multifilament 2 are respectively located in a separate Both sides of the round stick 7 are connected to a heavy object suspended in the air through a clamp 3, and the round stick 7 is separated to ensure that the two parallel parts of the dipped fiber multifilament 2 will not be bonded together. The two ends of the dipped fiber multifilament 2 are tightly wound on the silica gel strip 9 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coefficient of variation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com