Bag filling and packaging method and bag filling and packaging apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0063]First, the packaging method and packaging apparatus that maintains the amount of part gripped by a gripper pair at bag side edges constant for all bags will be described.

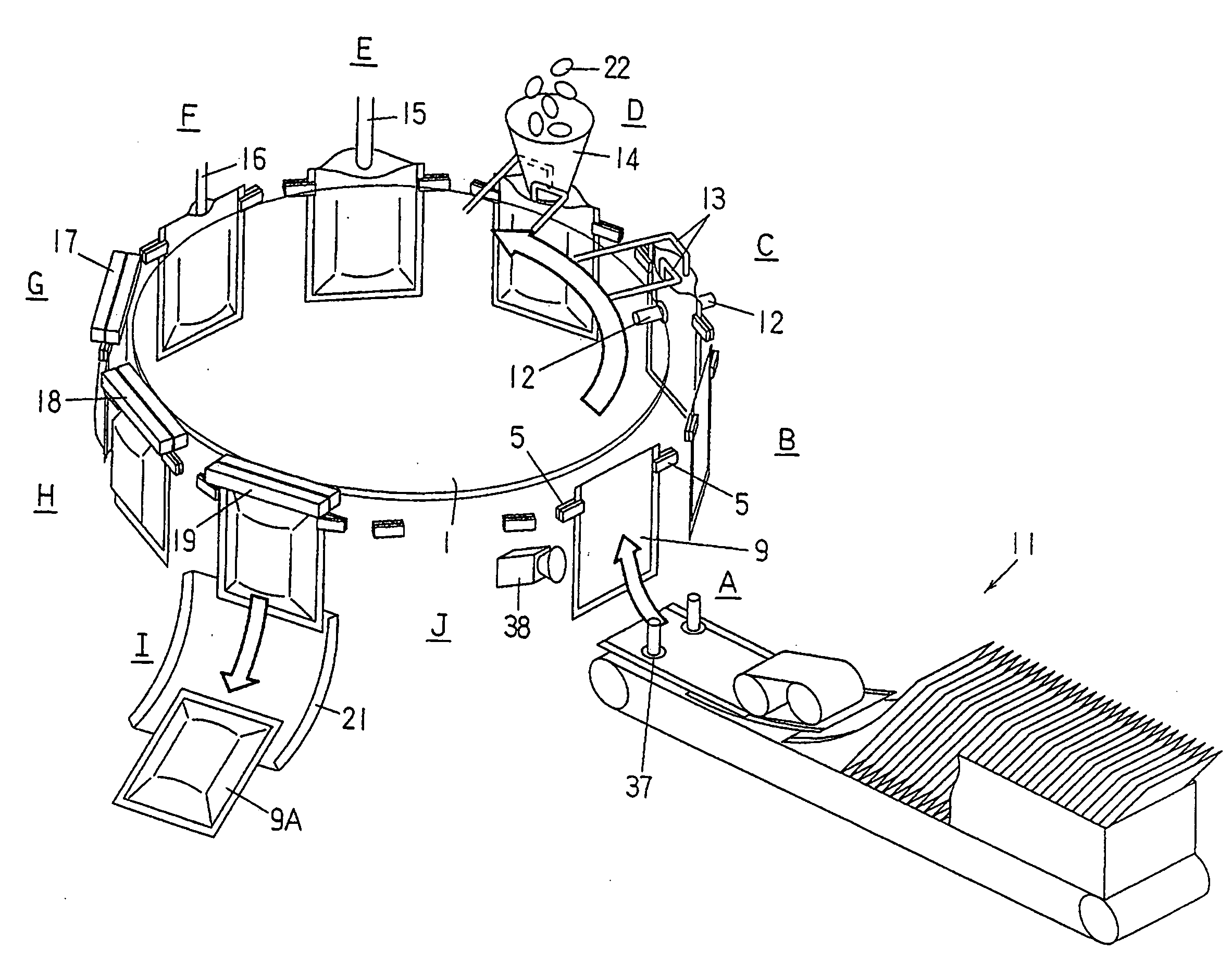

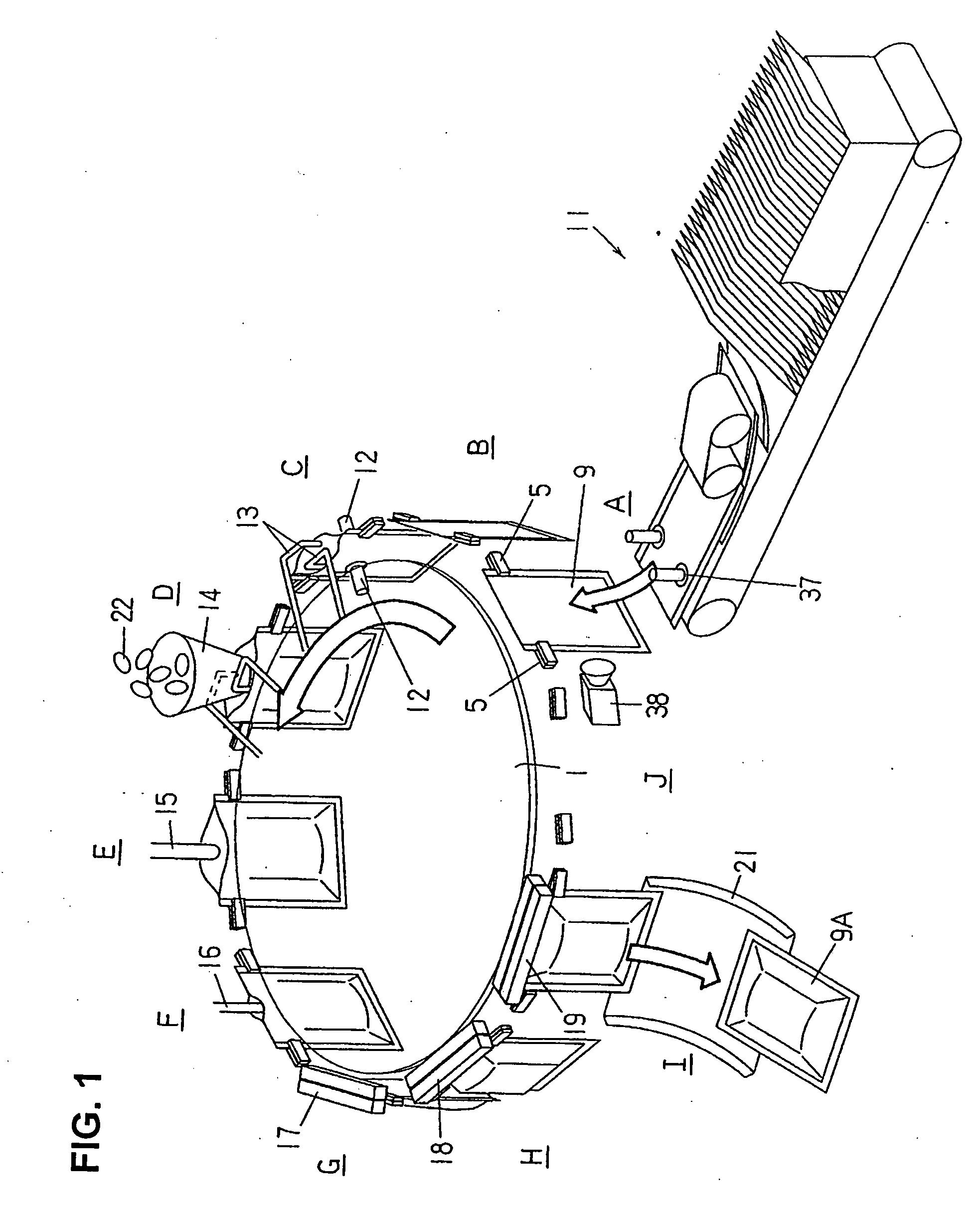

[0064]Overall Configuration of Rotary Type Bag Filling and Packaging Apparatus

[0065]In the rotary type bag filling and packaging apparatus shown in FIG. 1, a plurality of pairs of grippers 2 and 3 (only the chucks 5 and 5 thereof being shown in FIG. 1) for gripping the left and right side edges of each one of the bags 9 and suspending such bags are provided at equal distance along the circumference of a table 1 that intermittently or continuously rotates (in the rotating direction being shown by arrow).

[0066]At the various process positions A to J along the circumference of the table 1, various devices are provided. A conveyor magazine type bag feeder 11 is provided at position A, a printer (not shown) is provided at position B, a bag mouth opening device (only a pair of suction plates 12 thereof being shown) ...

second embodiment

[0100]Next, in the bag filling and packaging method and packaging apparatus according to the present invention, a packaging method and packaging apparatus in which when the bag mouth of a bag gripped by a gripper pair is tensioned by widening the gripper distance for the gripper pair, such tension is kept constant for (or applicable to) any and all bags will be described.

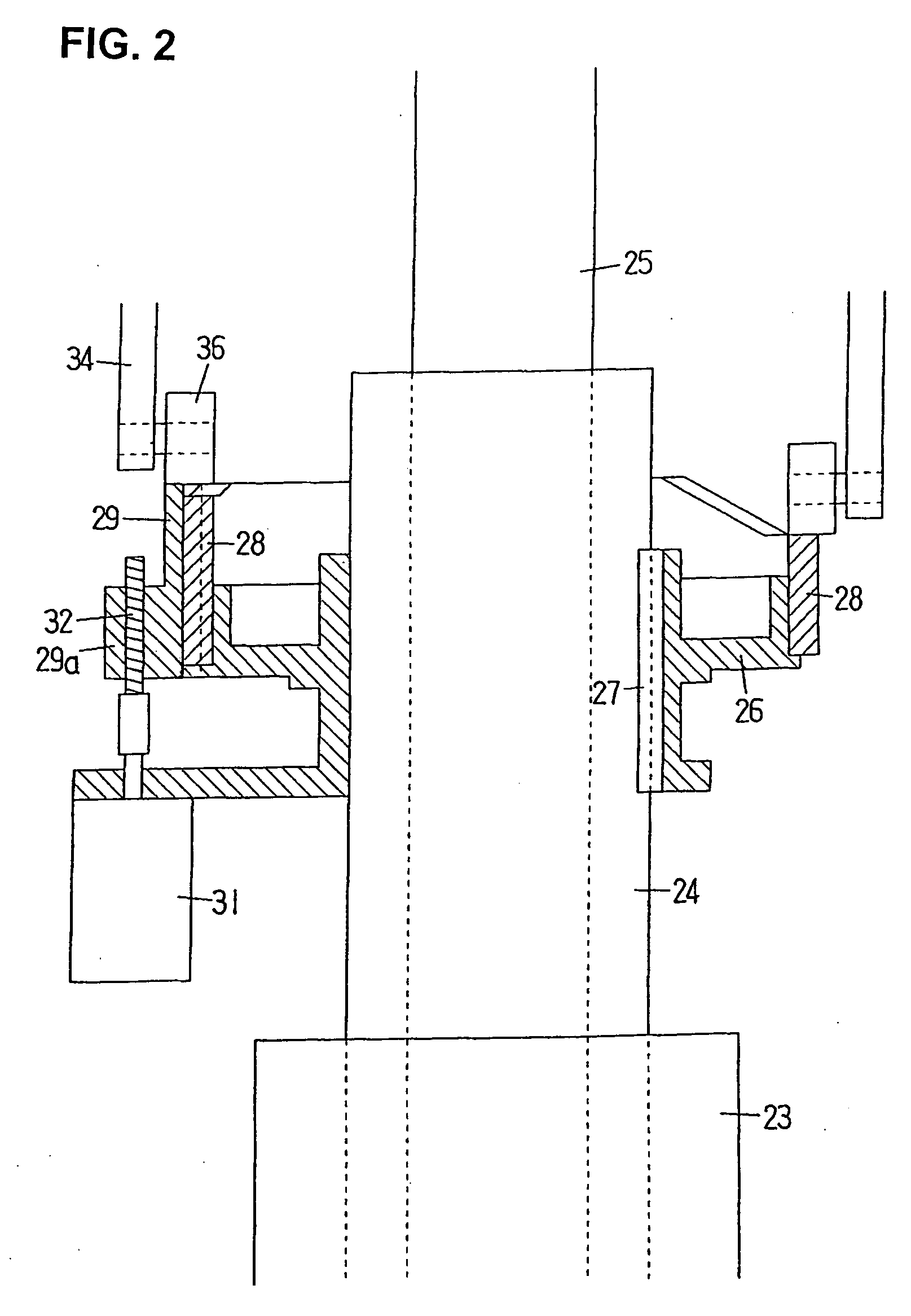

[0101]Distance Setting and Distance Adjusting Mechanism

[0102]As shown in FIG. 8, in a predetermined position in the circumferential direction of the gripper distance setting cam 28, a gripper distance adjustment auxiliary cam 41 is provided so as to be movable up and down in a configuration similar to the gripper distance adjustment auxiliary cam 29 in FIGS. 5 and 6. The position where the gripper distance adjustment auxiliary cam 41 is provided, however, differs from that of the gripper distance adjustment auxiliary cam 29. The drive mechanism for moving the gripper distance adjustment auxiliary cam 41 up and down ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com