Machine unit process for stretch bending, straightening and rewinding

A tension-bending straightening and tension-bending straightening technology, applied in the direction of bending workpieces, manufacturing tools, metal processing equipment, etc., can solve problems such as strip steel defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

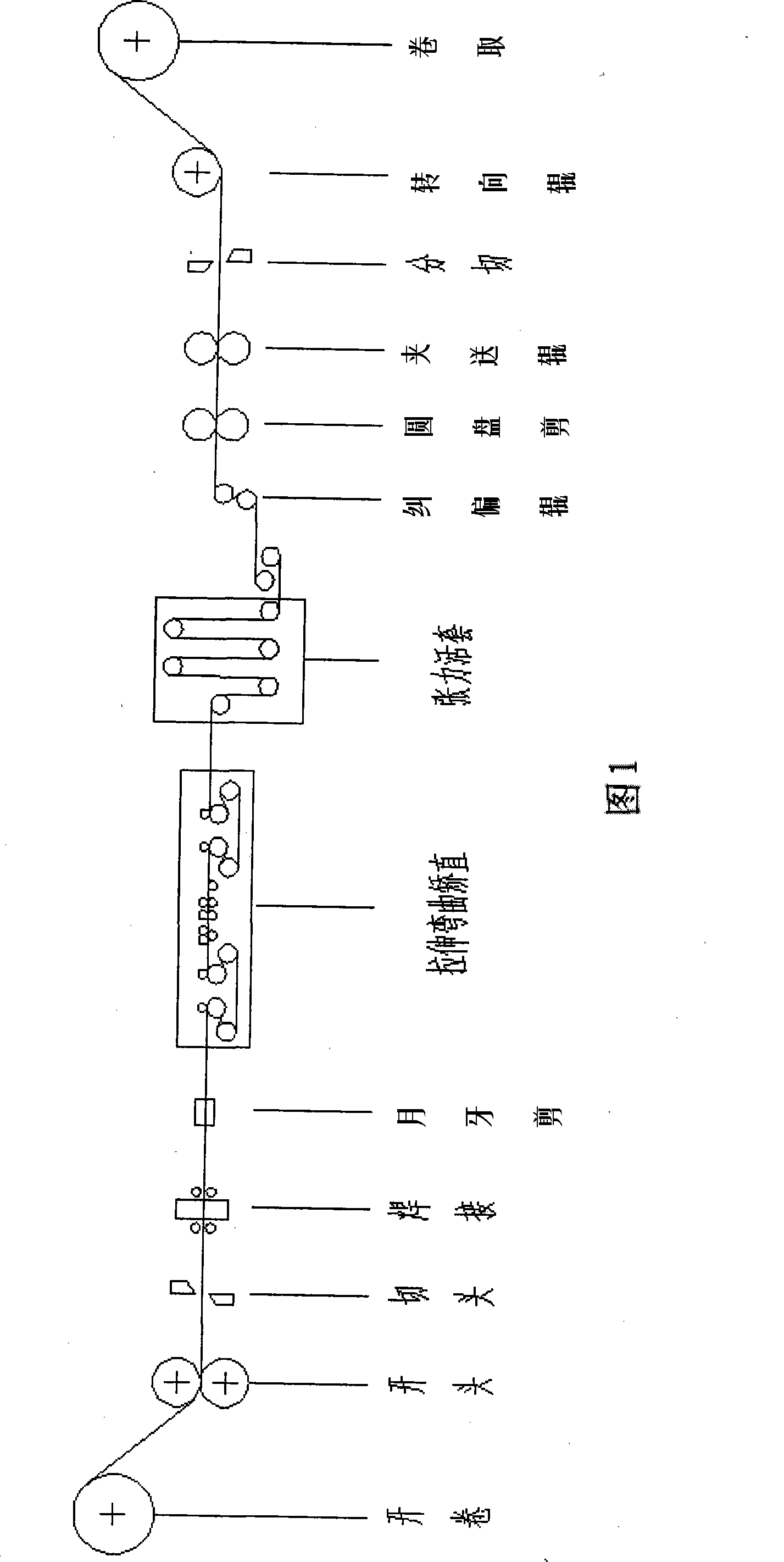

[0032] As shown in Figure 1, combined with some mature processes of the original recoiling unit and stretch bending straightening unit such as coiling, uncoiling, head cutting, coiling, unloading and other processes combined with the idea of the present invention, the basic process is formed: coiling → Uncoiling → Switching → Cutting head → Welding → Stretching, bending and straightening → Tension looper → Correction → Disc shearing edge → Pinch roller → Slitting → Steering roller → Coiling → Unloading. The equipment required for such a basic process includes: coiling trolley, uncoiler, entrance turning roller, head cutting shear, welding machine, crescent shear, entrance tension roller, stretch bending straightener, exit tension roller, tension looper, vertical deviation correction There are nearly 40 sets of equipment such as rolls, edge trimming disc shears, slitting shears, export turning rolls, and coilers.

[0033] When integrating the stretch bending straightening pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com