Micro-tension control system and control method for GDL fragile material

A technology of micro-tension control and brittle materials, which is applied to the device and coating of the surface coating liquid, can solve the problems that the micro-tension control of GDL brittle materials cannot be realized, and achieve stable tension control, convenient operation and high control efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

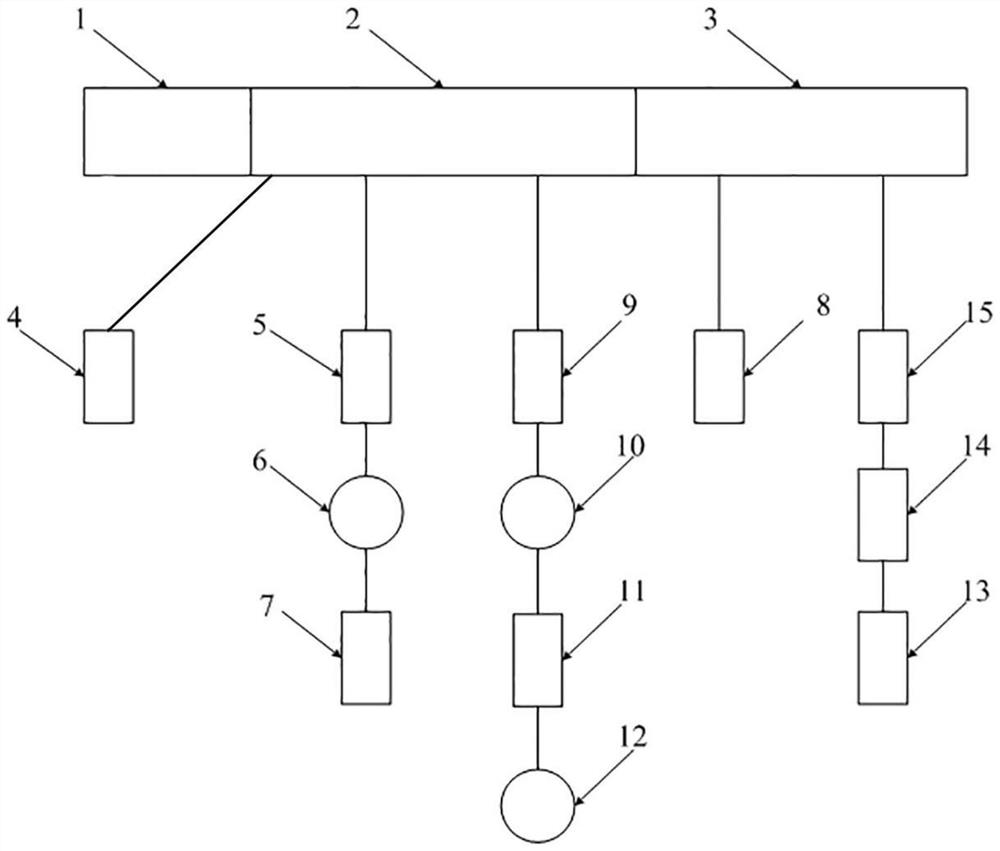

[0056] The microtension control system of the GDL brittle material of the present invention, such as figure 1 As shown, including the controller, detection mechanism and actuator;

[0057] The controller includes a power supply module 1, a CPU module 2, and an analog input and output module 3 connected in sequence, and the CPU module 2 is provided with a PID calculation module;

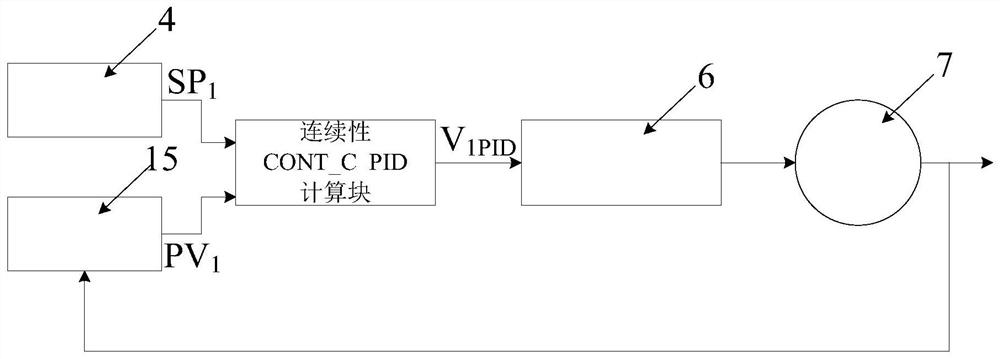

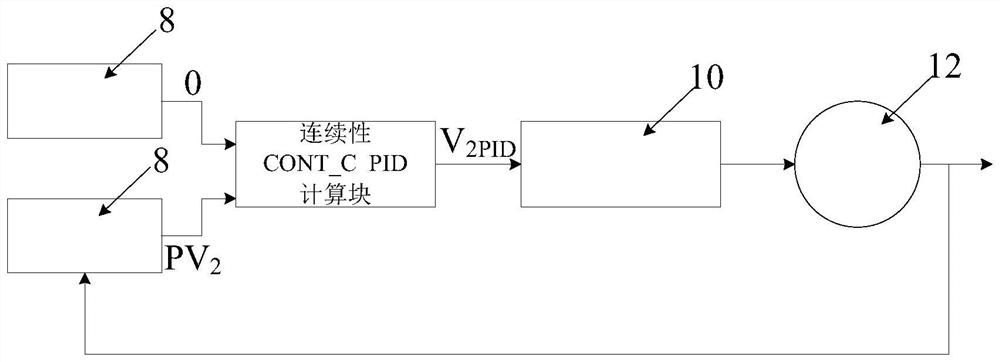

[0058] The actuator includes a floating pendulum roller servo driver 5, a floating pendulum roller servo motor 6, and a floating pendulum roller 7 connected in sequence, and also includes a driving roller servo driver 9, a driving roller servo motor 10, a reduction mechanism 11 and a driving roller 12 connected in sequence, The floating swing roller servo driver 5 and the driving roller servo driver 9 are both connected to the CPU module 2, and the CPU module 2 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com