Thermoplastic sheet forming machine

A thermoplastic sheet and molding machine technology, which is applied to other household appliances, household appliances, flat products, etc., can solve problems such as unsolved problems, and achieve the effects of uniform heating and stable tension control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

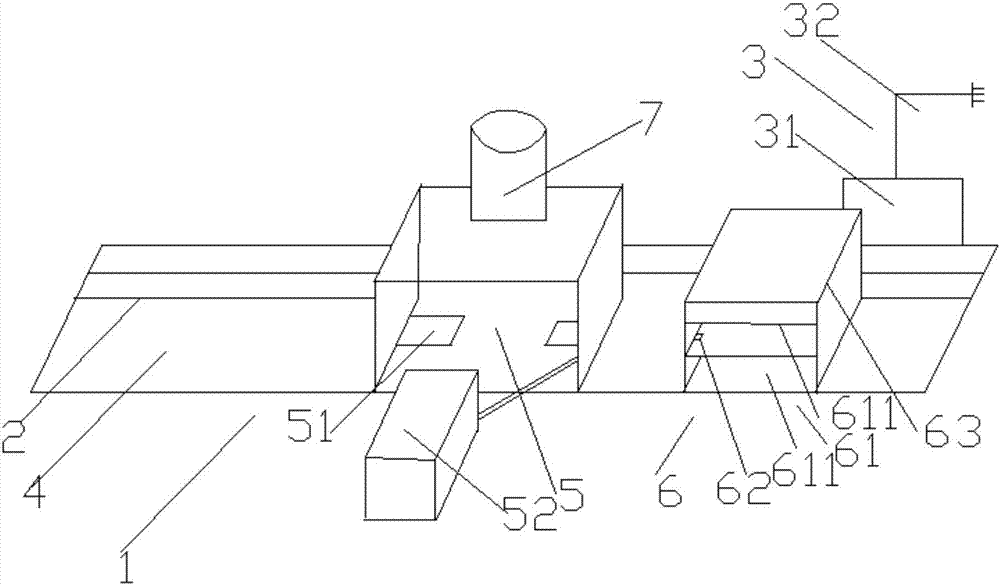

[0021] Such as figure 1 As shown, a thermoplastic sheet forming machine includes a frame 1, a track 2 and a mechanical arm 3 arranged on the frame 1, and a discharge area 4, a mold area 5, and a baking area 6 are sequentially arranged on the frame 1 , the discharge area 4 is connected with the baking area 6 through the track 2, the baking area 6 is connected with the mold area 5 through the track 2, the baking area 6 is provided with a ceramic heater 61 and a temperature sensor 62, and the mold area 5 is provided with several The mold 51 and the extremely cold and extremely hot device 52 connected with the mold 51 and the mechanical arm 3 are movable on the track 2 .

[0022] Specifically, the mechanical arm 3 includes an L-shaped arm 32 and an air cylinder 31 connected to the arm 32 , and the air cylinder 31 can adjust the tension of the arm 32 . The grasping portion of the arm 32 is provided with a steel cushion. Prevents damage to thermoplastic sheets.

[0023] Specifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com