Hot compress steam mask forming machine

A molding machine and mask technology, applied in bathing devices, physical therapy and other directions, can solve the problems of uneven feeding of hot compress steam masks, unsuitable hot compress steam masks, and ineffective absorption of masks, etc. , the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

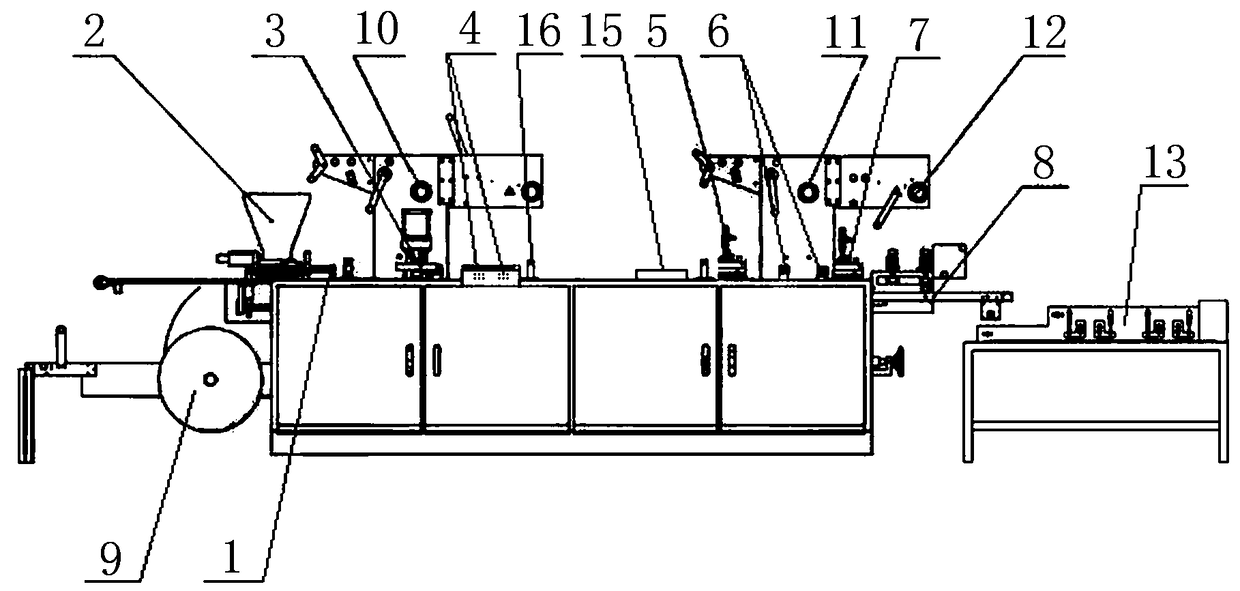

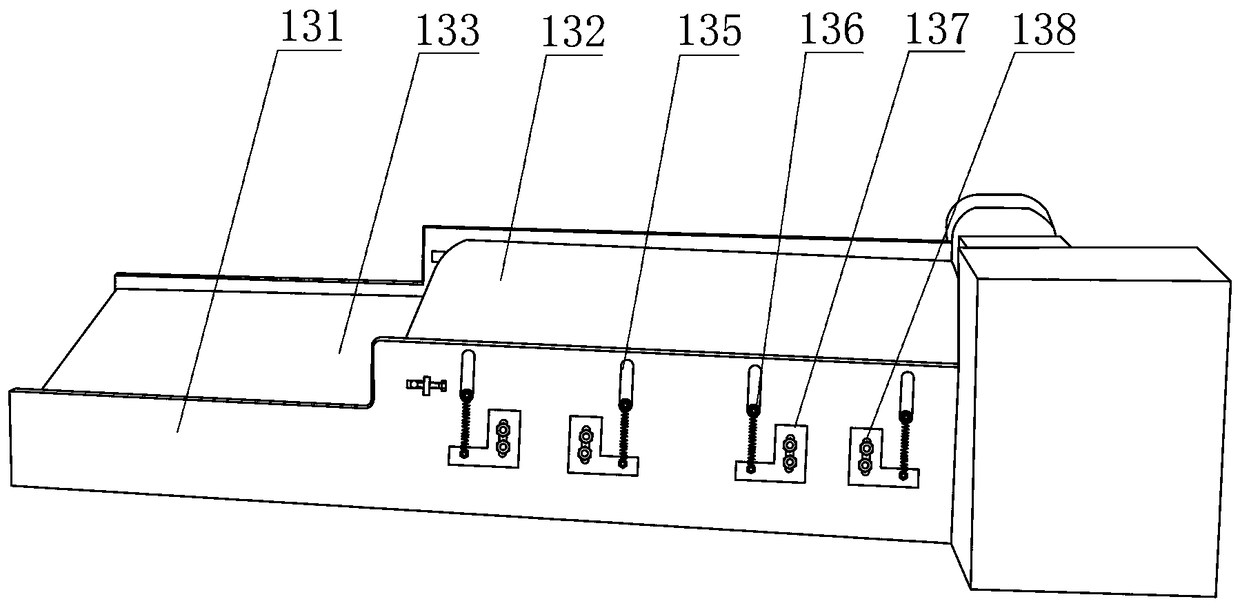

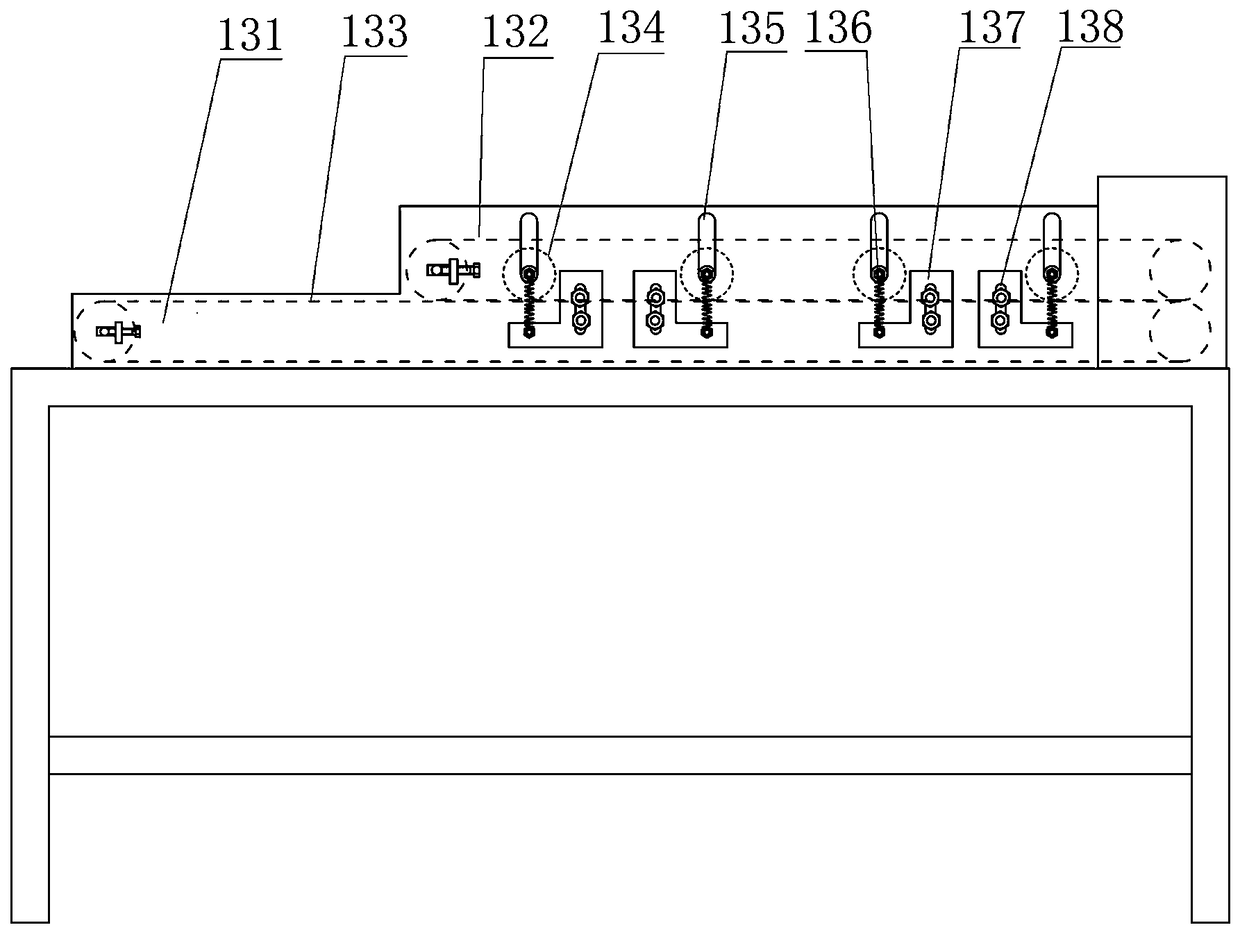

[0022] Embodiment one: if Figures 1 to 3As shown, in this embodiment, a hot compress steam mask forming machine includes a frame 1, and the frame is sequentially provided with a blanking device 2, a heat sealing device 3, a first air clamp conveying device 4, a first punch Cutting device 5, the second air clip transfer device 6, the second punching device 7 and the finished product conveying device 8, the first punching device 5 cuts out the cutting line of the eyes, nose and mouth position in the middle of the hot compress steam mask , the second blanking device 7 cuts out the profile of the hot compress steam mask, the lower front end of the unloading device 2 is provided with a mask bottom unwinding device 9, and the upper part of the frame 1 is behind the unloading device 2 The upper part is provided with a mask middle layer unwinding device 10, a mask surface layer unwinding device 11 and a mask waste rewinding device 12, and the front of the heat sealing device 3 is pro...

Embodiment 2

[0028] Embodiment two: if Figures 4 to 5 As shown, in the present embodiment, the unloading device 2 includes a platform bottom plate 21, a lifting frame 22, a discharge plate 23, a material guide plate 24 and a hopper 25, and the discharge plate 23 and the material guide plate 24 are arranged on the lifting platform. On the frame 22 and can lift above the platform bottom plate 21 with the lifting frame 22, the first guide rail 26 and the first cylinder 27 are provided on the lifting frame 22, and the material guide plate 24 is slidably arranged on the first guide rail 26, so The first cylinder 27 is connected to one side of the material guide plate 24, the material guide plate 24 is provided with a plurality of material guide ports, the hopper 25 is placed on the material guide plate 24 and its hopper outlet communicates with the material guide port , the discharge plate 23 is located below the material guide plate 24 and the discharge plate 23 is provided with a plurality o...

Embodiment 3

[0032] Embodiment 3: not shown in the figure, in this embodiment, the unwinding shafts of the mask bottom layer unwinding device 9 , mask middle layer unwinding device 10 and mask surface layer unwinding device 11 are all connected to a constant tension controller.

[0033] Other structures of this embodiment are the same as those of the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com