Power distribution station motor stator core fixing device

A stator core and fixing device technology, applied in the manufacture of the stator/rotor body, etc., can solve the problems of inconvenient fixing, poor replacement, vibration, etc., and achieve the advantages of convenient and quick adjustment of the fixed height, high fixing firmness, and improved stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

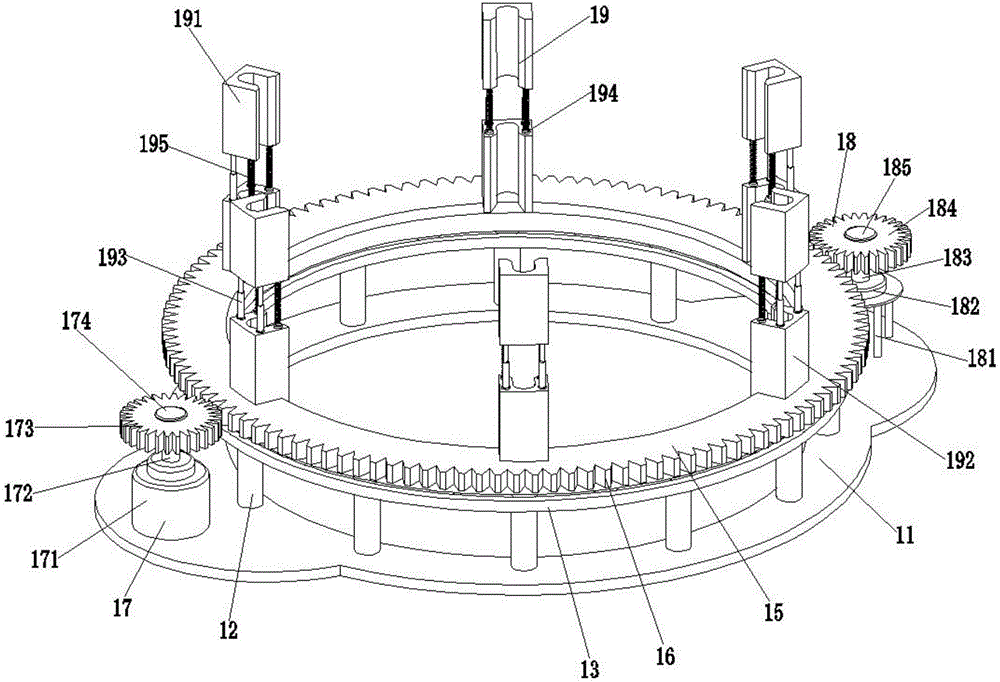

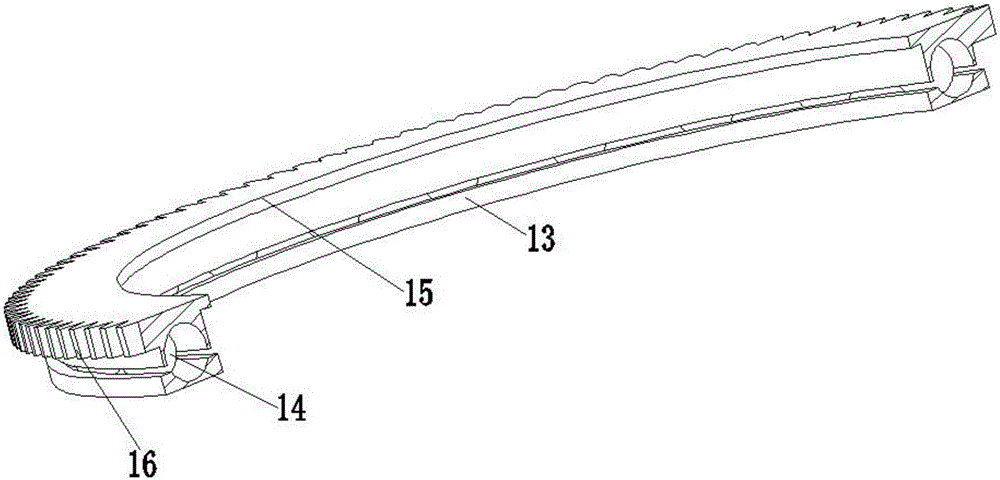

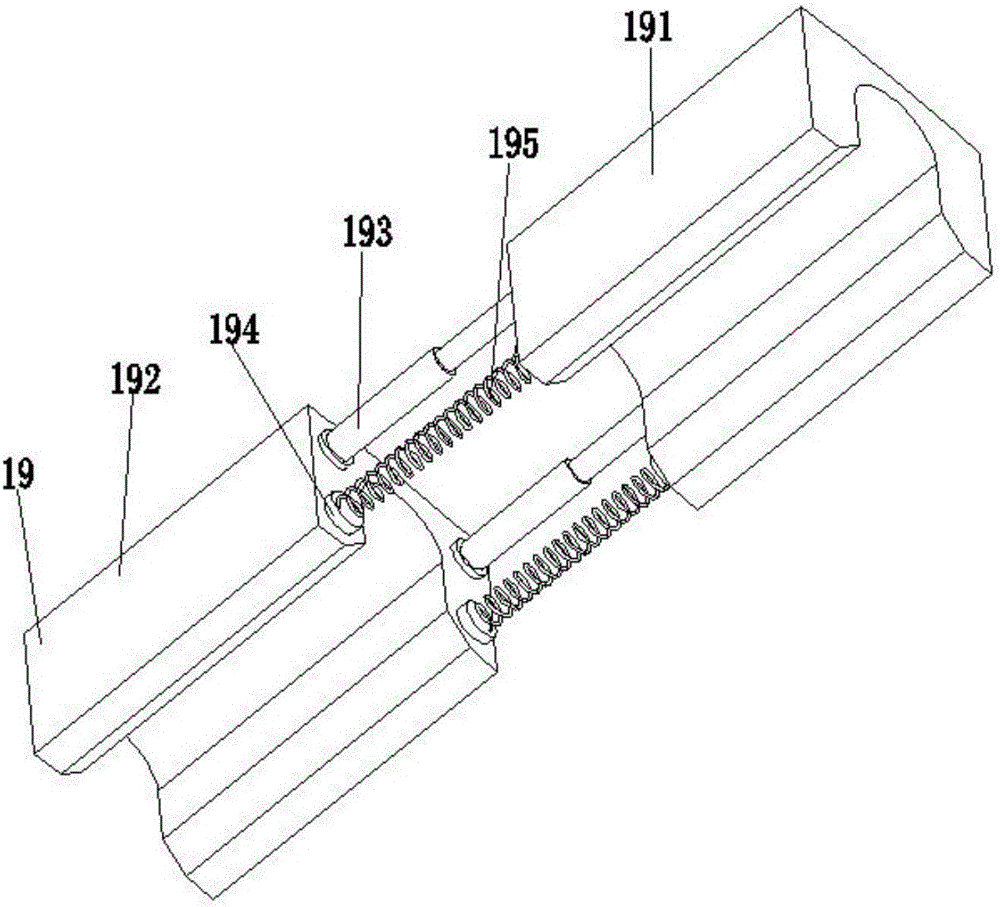

[0018] Such as Figure 1 to Figure 3 As shown, a stator core fixing device for a substation motor includes a chassis base 11, a support rod 12, a ring guide rail 13, a rotating ball 14, a rotating disk 15, a driven gear 16, a power output mechanism 17, and a limit mechanism 18 and support fixing mechanism 19; the middle part of the chassis seat 11 is provided with a chip leakage hole, and the left and right sides of the chassis seat 11 are respectively symmetrically provided with semicircular convex seats, and the support rod 12 is located between the chassis seat 11 and the annular guide rail 13, and The support rods 12 are arranged at equal intervals along the circumferential direction of the chip leakage hole edge on the chassis base 11, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com