Oil fume purifier and manufacturing method thereof

A fume purifier and anode plate technology, applied in the direction of electrode structure, electrostatic separation, etc., can solve the problems of high manufacturing precision, many dead spots for maintenance and cleaning, and complicated installation, so as to achieve high space utilization, avoid cleaning difficulties, increase The effect of large purification area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

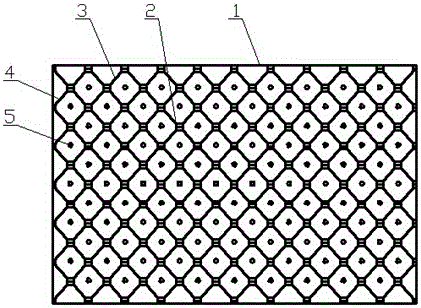

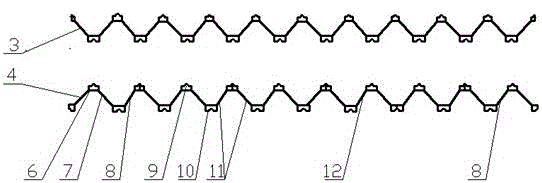

[0046] Referring to the accompanying drawings: the oil fume purifier includes a housing 1, 8 sets of anode plates 2 and cathode wires 5, the anode plates 2 and the cathode wires 5 are installed in the housing 1, and the anode plates 2 form a closed cylindrical shape, The cathode line 5 is located in the middle of the cylindrical anode plate 2, and the two ends of the cylindrical anode plate 2 are respectively provided with an air inlet and an air outlet for the flue gas to enter and exit. The anode plate 2 is composed of an integrated folded plate 3 and The assembled folded plate is composed of 4 splicing.

[0047] This structure has a high utilization rate of the space in the oil fume purifier housing 1, and the cross section of the pipeline in the anode plate 2 is octagonal. Compared with the hexagonal anode plate 2, the shape of the octagonal cross section is closer to The shape is circular, and the distribution of the electric field intensity is more uniform; and the anode...

Embodiment 2

[0058] Compared with Example 1, the lampblack purifier of this example has the following differences:

[0059] The oil fume purifier includes a casing 1 , 8 sets of anode plates 2 and cathode wires 5 . The anode plate 2 is composed of assembled folded plates 4 spliced together.

[0060] The assembled folded plate 4 includes a first assembled folded plate 18 and a second assembled folded plate 19 .

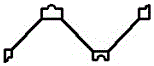

[0061] The first assembled folded plate 18 is made up of 5 second unit folded plates 17, and the second assembled folded plate 19 is composed of a first unit folded plate 8 installed on one side, another Three first unit folded plates 8 on the side and two second unit folded plates 17 installed in the middle.

[0062] The second unit folded plate 17 is composed of two folded units, in which the length of the short straight side 6 is 30% of the length of the long hypotenuse 7 .

[0063] The oil fume purifier composed of the above-mentioned assembled folding plate 4 has a high u...

Embodiment 3

[0068] Compared with Example 1, the lampblack purifier of this example has the following differences:

[0069] The oil fume purifier includes a casing 1 , 8 sets of anode plates 2 and cathode wires 5 . The anode plate 2 is composed of one-piece folded plates 3 spliced together.

[0070] The one-piece folded plate 3 comprises a first one-piece folded plate 20 and a second one-piece folded plate 21, and both the first one-piece folded plate 20 and the second one-piece folded plate 21 contain 13 An integrally formed folded plate with two identical folded units.

[0071] The outer sides of the first one-piece folded-shaped plate 20 odd-numbered short straight sides 6 and the outer sides of the even-numbered short straight sides 6 are respectively provided with male joints, circular male joints 9 and circular female joints 10, and the second integral folded-shaped plate 21 is even-numbered short A male circular male joint 9 and a circular female joint 10 are arranged on the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com