Roll material dynamic storing apparatus with tension control

A tension control and coil technology, applied in the direction of coiling strips, mechanical equipment, transmission devices, etc., can solve problems affecting the processing efficiency of the coil production line, loose structure, and complexity, and achieve compact structure, reasonable settings, and tension control wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

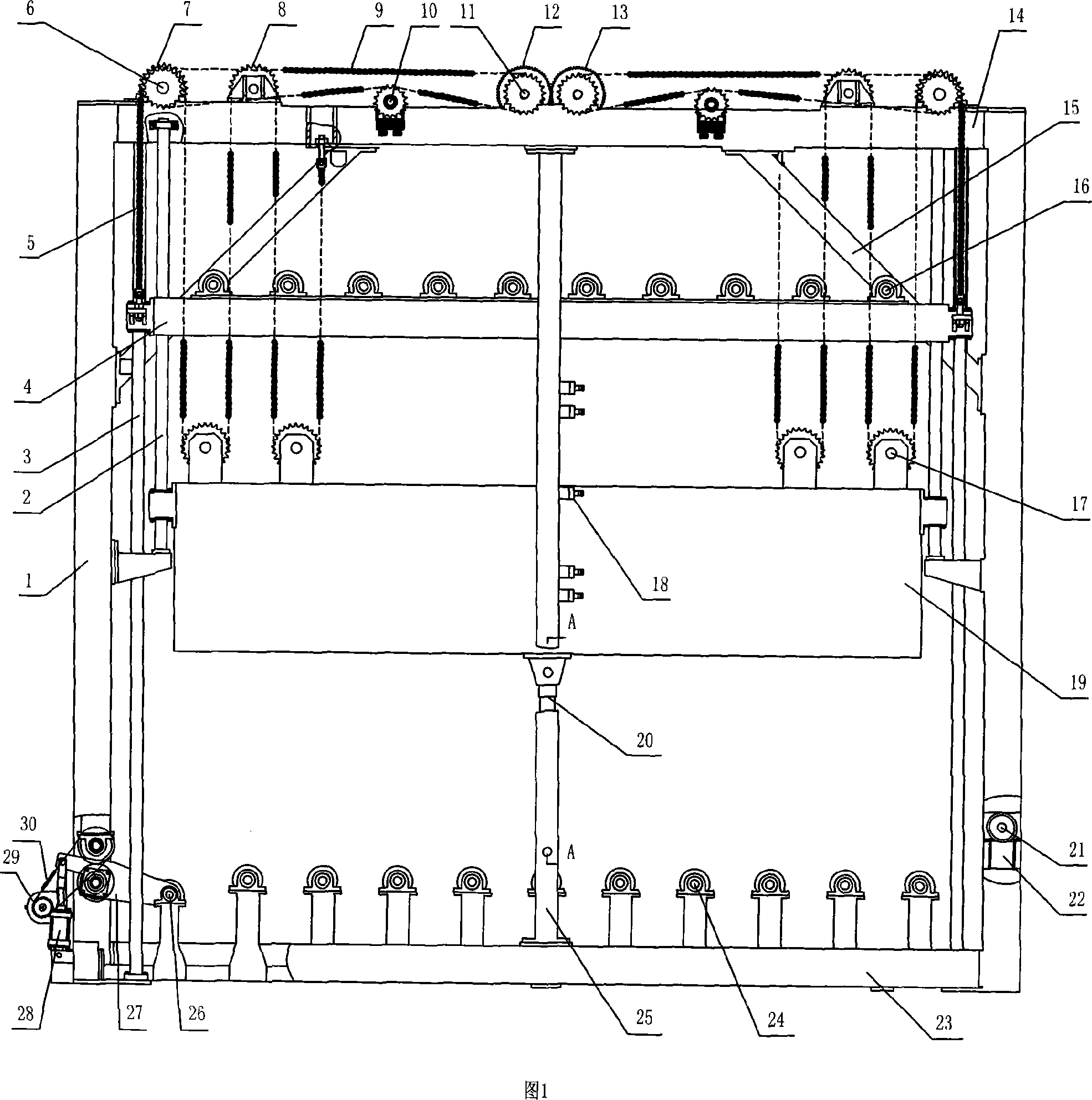

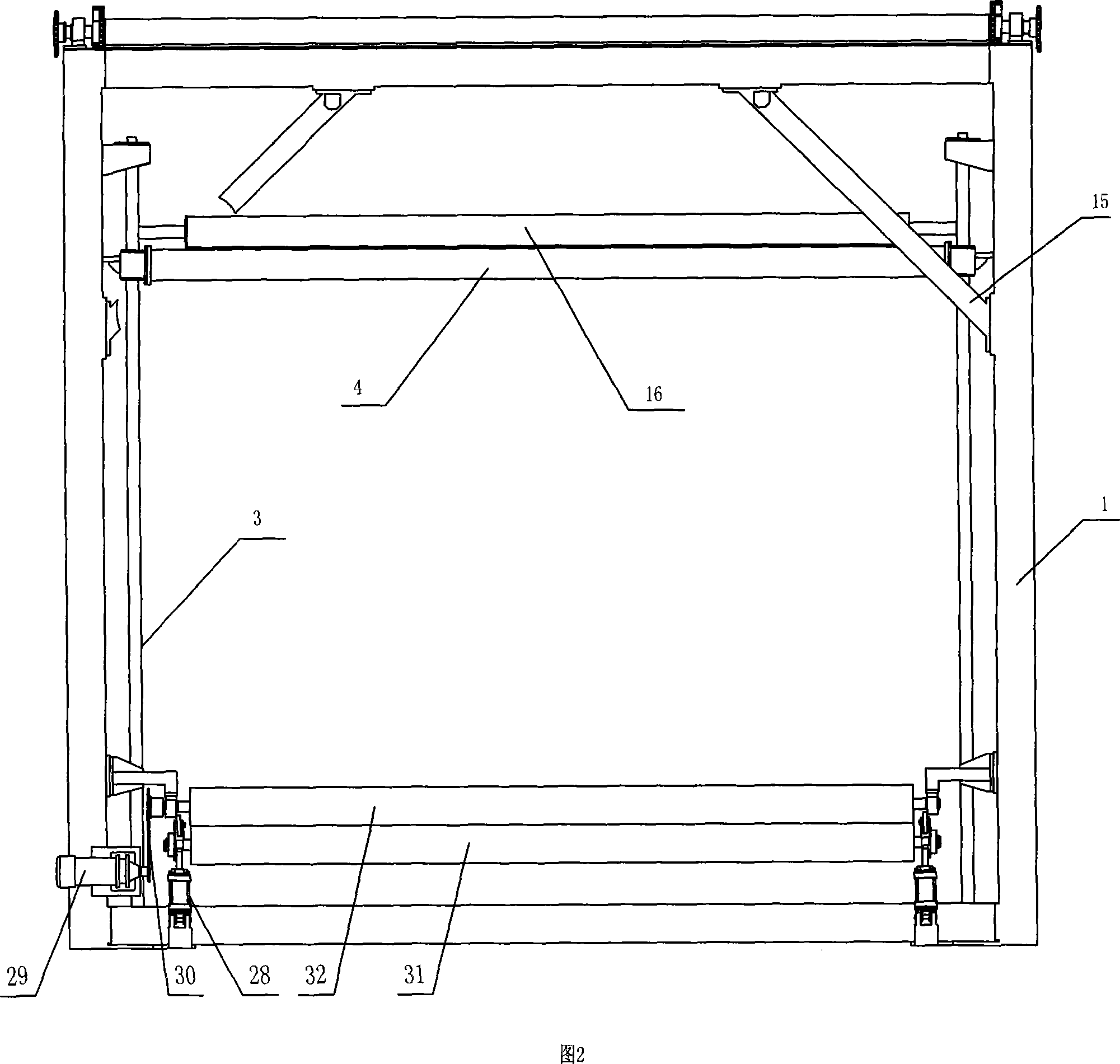

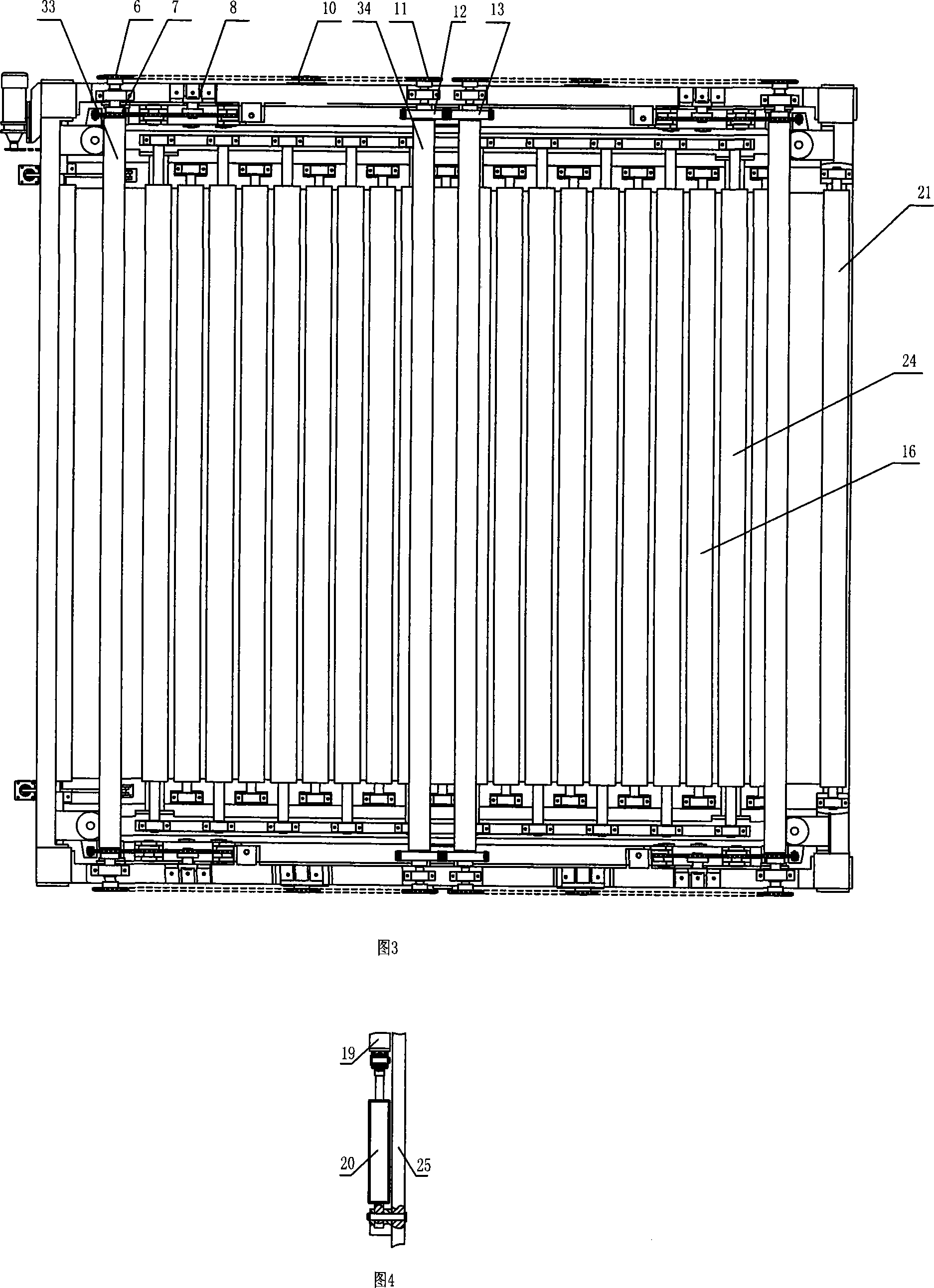

[0018] Including the main frame, the main frame is a rectangular cubic frame, which is composed of four-cornered side columns 1, upper and lower beams 14, 23, and an intermediate column 25 is also installed between the upper and lower beams in the middle of the main frame. Both sides of the main frame are also provided with diagonal braces 15, and the middle column is provided with a position detection switch 18, and the storage capacity of the coil is judged by detecting the position of the counterweight 19. The bottom of the main frame is provided with a fixed row of rollers 24, and the fixed row of rollers is composed of rollers arranged in parallel and spaced apart and fixed on the bottom of the main frame. An input roller configured with a tension detector is provided below one end of the main frame, and the input roller configured with a tension de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com