Routing mechanism of winding machine

A winding machine and wire structure technology, which is applied in coil manufacturing, electromechanical devices, and motor generator manufacturing, can solve problems such as uneven tension control of enameled wires, inability to ensure consistent tension, and uneven shape of stator coils, etc., to achieve perfection Winding process, simple structure, smooth tension control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing, but not as limiting the present invention:

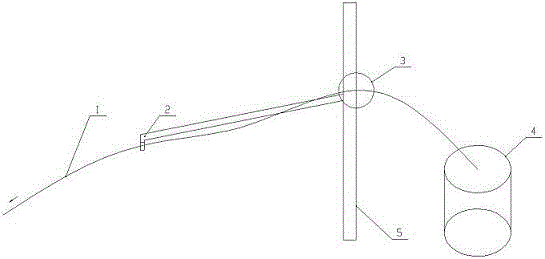

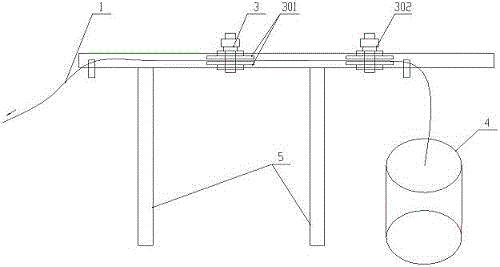

[0011] A wiring structure of a wire winding machine, comprising an enameled wire 1, a wire passing mechanism 3, and a cage 5, and the cage 5 is provided with a wire passing mechanism 3; after the enameled wire 1 is drawn out from the enameled wire reel 4, it passes through the wire mechanism 3 to enter the winding machine, the wire passing mechanism 3 is composed of several wool felts 301 arranged up and down, and each wool felt 301 is provided with an adjusting nut 302, and the enameled wire 1 passes through the wool felts 301 arranged up and down.

[0012] During specific implementation, after the enameled wire 1 is drawn from the enameled wire reel 4, the wool felt 301 of the wire mechanism 3 enters the winding machine, and the tension of the enameled wire 1 is controlled by the adjusting nut 302. The tightening force between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com