Telescopic machine tail self-adaptive adjustment electro-hydraulic composite control system and method

An adaptive adjustment, electro-hydraulic composite technology, applied in the direction of general control system, control/regulation system, electrical program control, etc., can solve problems such as too loose or too tight, to increase effective power, reduce loss, and improve equipment start-up rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

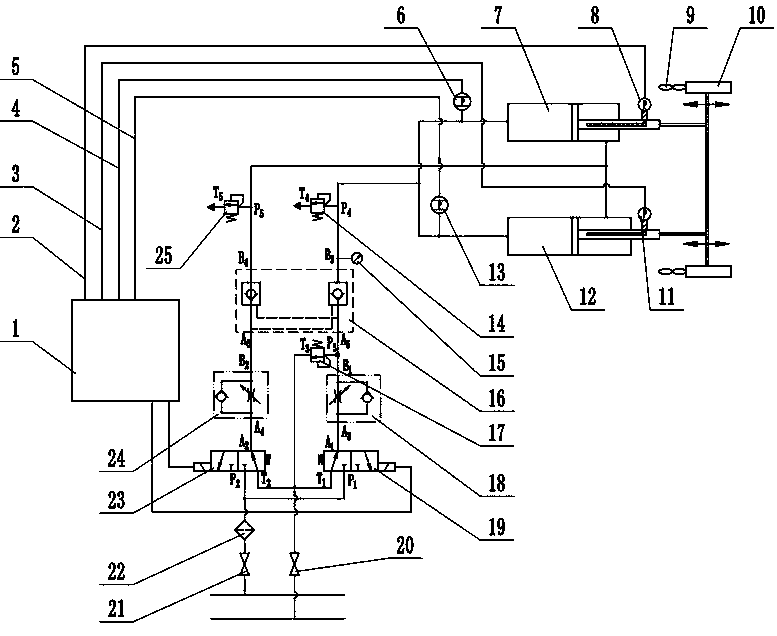

[0020] The present invention adopts the following technical solutions: an electro-hydraulic compound control system and strategy for self-adaptive adjustment of a retractable tail, which features a PLC calculation control center 1, stroke signal transmission line I2, stroke signal transmission line II3, and pressure signal transmission line I4 , Pressure signal transmission line Ⅱ5, pressure sensor Ⅰ6, tensioning cylinder Ⅰ7, stroke sensor Ⅰ8, chain 9, retractable tailstock 10, stroke sensor Ⅱ11, tensioning cylinder Ⅱ12, pressure sensor Ⅱ13, safety valve Ⅰ14, pressure gauge 15 , Double hydraulic control check valve 16, overflow valve 17, speed control valve Ⅰ18, reversing solenoid valve Ⅰ19, stop valve Ⅰ20, stop valve Ⅱ21, filter 22, reversing solenoid valve Ⅱ23, speed control valve Ⅱ24 and safety valve II 25.

[0021] The pressure sensor I6 and the pressure sensor II13 are respectively arranged between the piston rodless chamber side of the tensioning cylinder I7 and the tens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com