Automatic cable inverting machine of logging cable

A rope rewinding machine and cable technology, which is used in the transportation of filamentous materials, thin material handling, transportation and packaging, etc., can solve the problems of large occupied space, time-consuming and laborious, and poor tension control. Simple, good tension control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

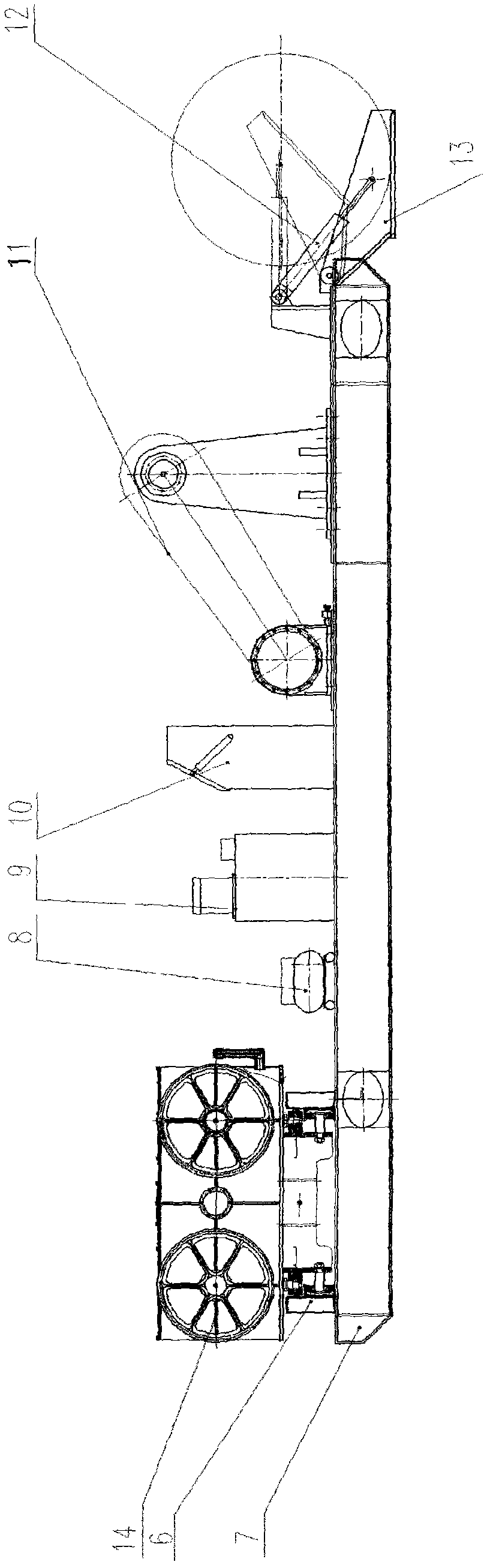

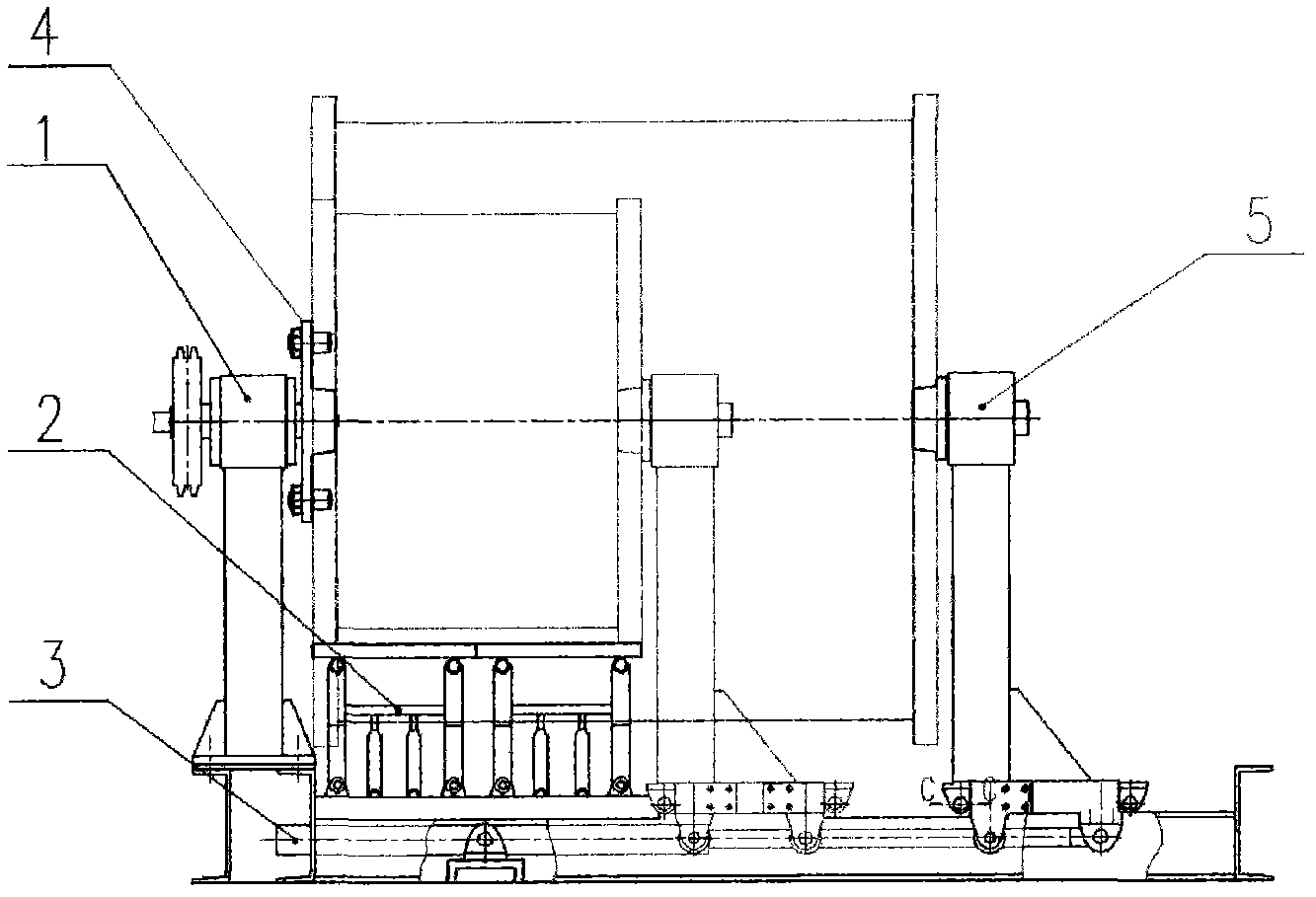

[0010] Such as figure 1 , figure 2 As shown, the logging cable automatic rewinding machine of the present invention includes a fixed support (1), a small scissor lift (2), an oil cylinder (3), a support head (4), a movable support (5), Cable discharge device assembly (6), skid frame (7), air compressor (8), hydraulic station (9), operation console (10), chain drive (11), oil cylinder (12), lifting bucket ( 13), gear box (14), linear displacement encoder, travel switch, tension sensor, air brake, hydraulic valve, touch screen, PLC (programmable logic controller).

[0011] The lifting bucket (13) is connected to the top of the skid frame (7) through the oil cylinder (12), the chain transmission device (11) is arranged above the skid frame (7), and one side of the chain transmission device (11) is close to the oil cylinder (12) . Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com