Asymmetric damping tensioner belt drive system

A technology of transmission system and tensioning wheel, which is applied in the direction of gear transmission, transmission, belt/chain/gear, etc., and can solve problems such as belt tension that cannot be completely solved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

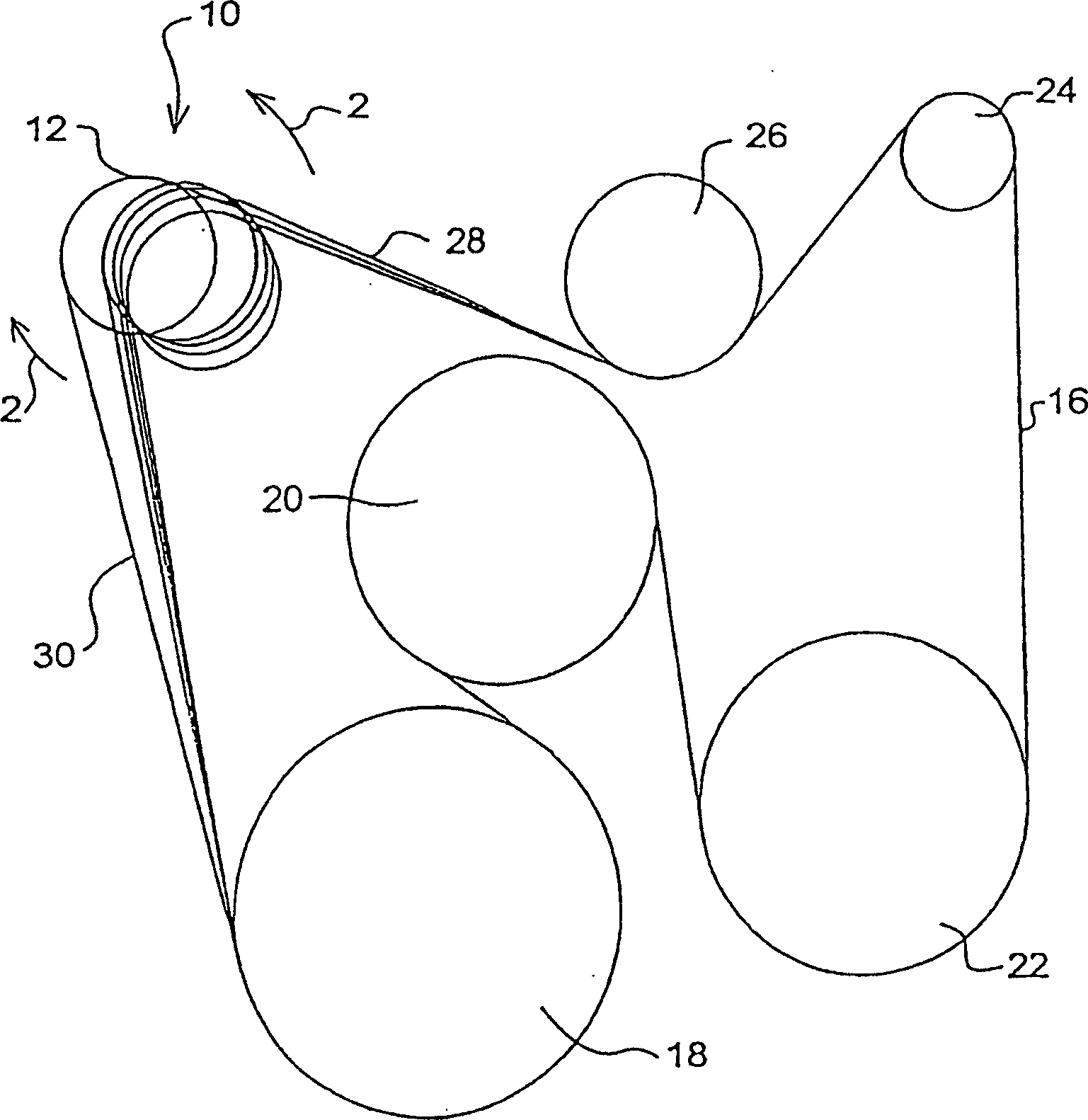

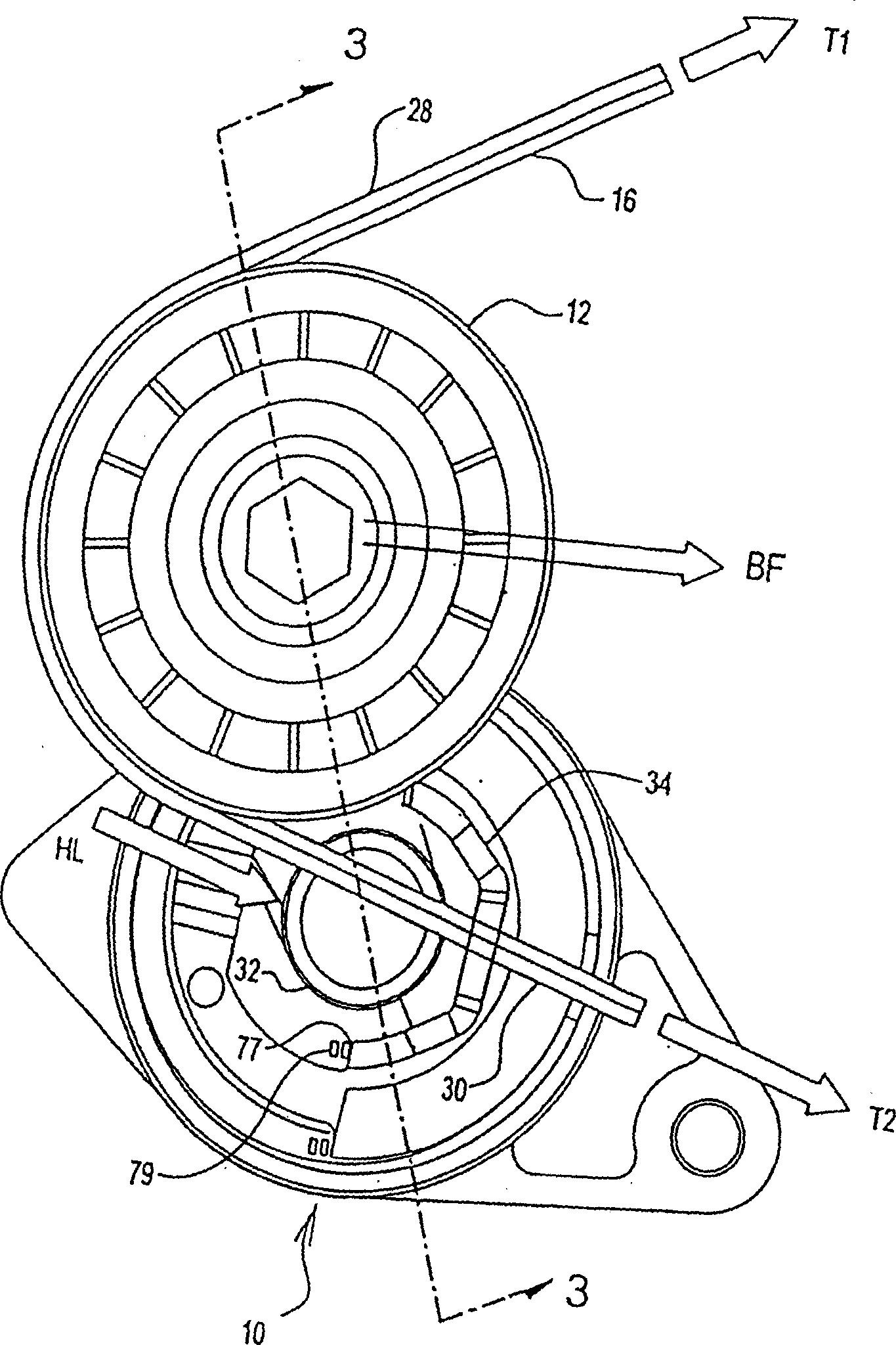

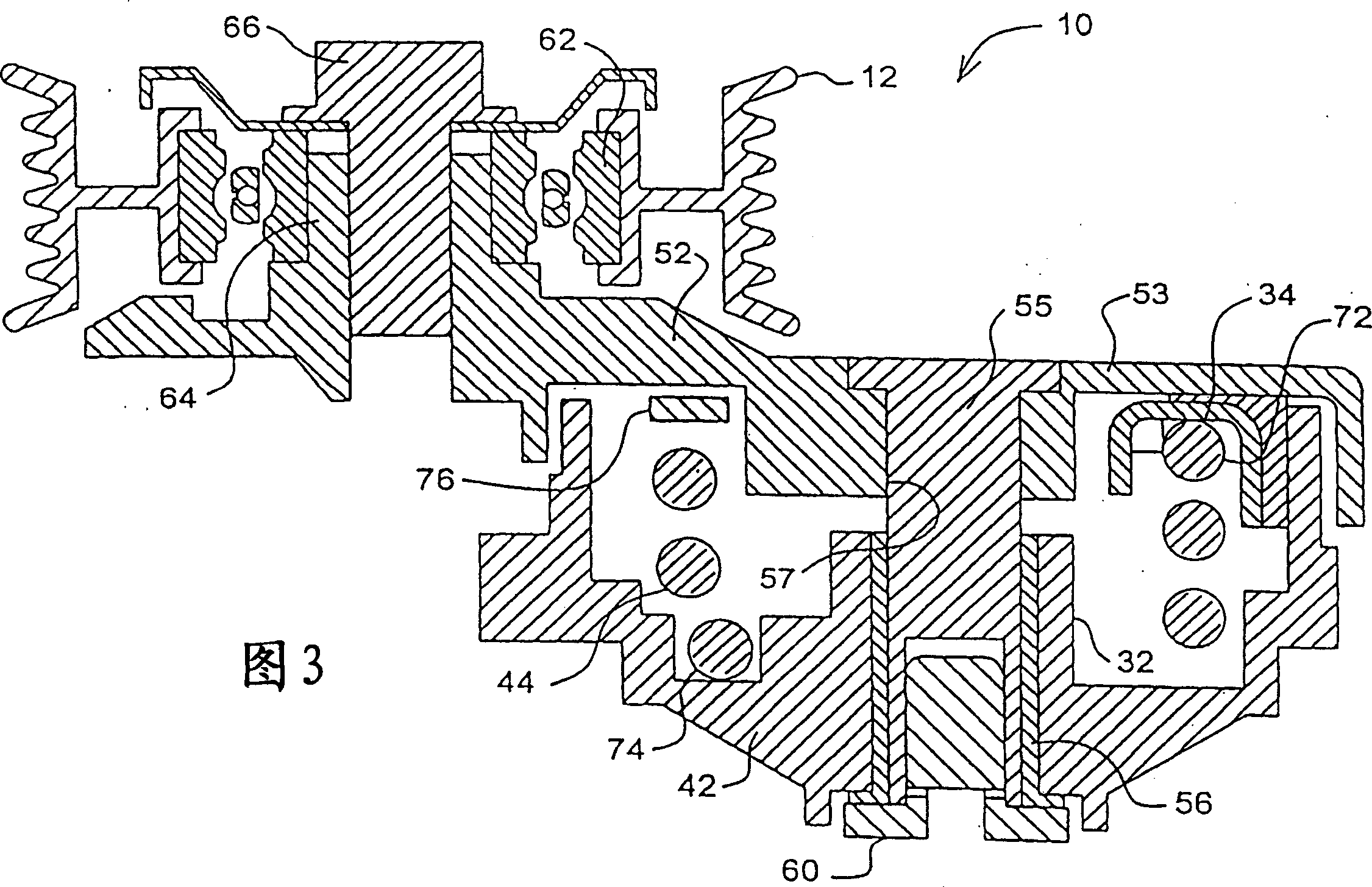

[0060] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENT

[0061] Described here are tensioning pulleys with asymmetric damping characteristics. Assuming that the asymmetric tensioner and the ordinary tensioner have the same tensioner force, the asymmetric tensioner consumes more energy than the ordinary tensioner. Another major advantage of an asymmetric tensioner is that it can provide a higher degree of damping for a given belt drive system than a normal tensioner.

[0062] There are two main differences in the operation of an asymmetric tensioner and a normal tensioner. First, in the half-cycle of the tensioner loaded, the frictional force of the asymmetric tensioner and thus the vibration energy consumed is significantly higher than the frictional force and energy of the unloaded half-cycle of the tensioner. For ordinary tensioners, these forces are basically equal. Secondly, due to the partial damping function of the tensioner, the belt drive energy is only dissipated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com