Continuous annealing line gear coupling fault detection device, system and method

A gear coupling and fault detection technology, which is applied in the direction of measuring devices, machine/structural component testing, instruments, etc., can solve the problems of maintenance delay and fault detection lag, so as to improve safety, reduce downtime, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

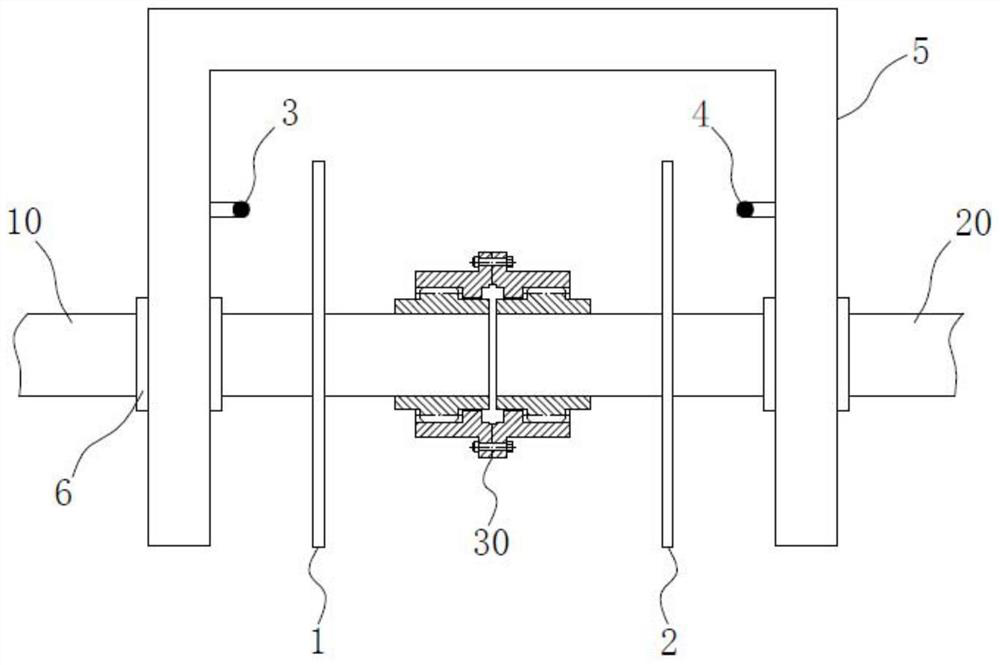

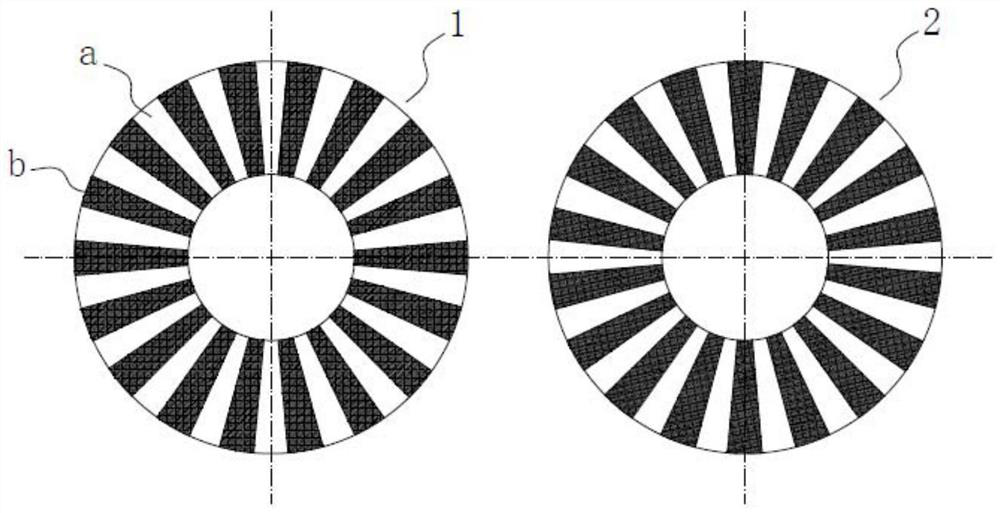

[0035] like figure 1 and figure 2 As shown in , a device for fault detection of a gear coupling with continuous retraction line in this embodiment includes a first ring grating 1 and a second ring grating 2, the two ring gratings have the same structure, and both have fan-shaped light-shielding areas a and the light-transmitting area b, the light-shielding area a and the light-transmitting area b are uniformly and alternately distributed around the axis of the ring grating; a photoelectric sensor is also included, and the photoelectric sensor has a light source emitting end 3 and a receiving end 4; the two The ring gratings are coaxially fitted and fixedly connected with the driving shaft 10 and the driven shaft 20 connected to the two ends of the gear coupling 30 respectively, and the light-shielding area a on the first ring grating 1 and the transparent area a on the second ring grating 2 The light zone b overlaps in the axial direction, the light source emitting end 3 and...

Embodiment 2

[0040] This embodiment provides a detection system including the fault detection device for the gear coupling with continuous withdrawal line described in Embodiment 1. The detection system is used for real-time detection and monitoring of whether the gear couplings in the continuous withdrawal line have wear, sliding teeth and broken teeth.

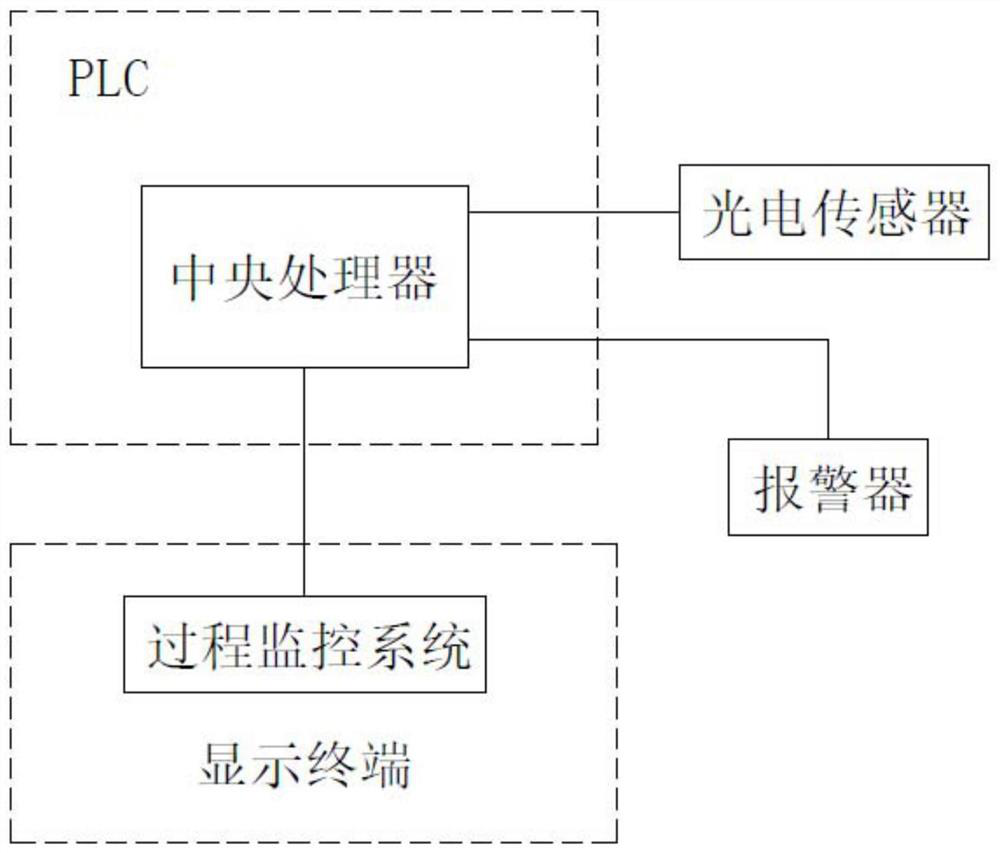

[0041] like image 3 As shown in , the detection system in this embodiment includes several detection devices and PLC control systems that correspond one-to-one to the gear couplings 30 in the continuous withdrawal line, and the photoelectric sensors in the detection devices are connected to all The PLC control system is used to receive and analyze the signal fed back by the receiving end 4 of the photoelectric sensor through the PLC control system, and output prompt information to the staff.

[0042] like image 3 As shown in , the detection system in this embodiment also includes several alarms connected to the PLC control system, an...

Embodiment 3

[0046] This embodiment provides a detection method based on the detection system described in Embodiment 2, the steps are:

[0047] 1. While starting the continuous retreat line, the light source transmitting end 3 of the photoelectric sensor at the position of each gear coupling 30 is controlled by the PLC control system to continuously emit light signals to its receiving end 4;

[0048] 2. The PLC control system scans the feedback signal of the photoelectric sensor at the position of each gear coupling 30 with a signal scanning period of 100 ms. When the gear coupling 30 at a certain position has wear, slipping and broken teeth , the receiving end 4 of the photoelectric sensor at this position converts the received optical signal into an electrical signal and feeds it back to the central processing unit of the PLC control system;

[0049] 3. After receiving the signal, the central processor of the PLC control system sends an instruction to the alarm at the corresponding posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com