Nylon mother yarn warping method and nylon mother yarn warping device

A technology of nylon and mother yarn, which is applied in the field of nylon mother yarn warping method and nylon mother yarn warping device, which can solve the problem of increasing the difficulty and complexity of the warping process operation, improving the difficulty of nylon yarn warping, and low production efficiency, etc. problems, to achieve the effect of simplifying the number of drive motors, reducing the time for disassembly and assembly, and reducing the occupied area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

[0028] Example. The nylon mother yarn warping method is characterized in that, comprising the following steps:

[0029] ① According to the conventional process, nylon 6 is sliced into nylon sub-yarns, and 10 nylon sub-yarns are intertwined to form a nylon parent yarn with a thickness of 30D (Daniel), and the nylon parent yarn is wound on a cylinder to obtain a parent yarn. yarn spindle;

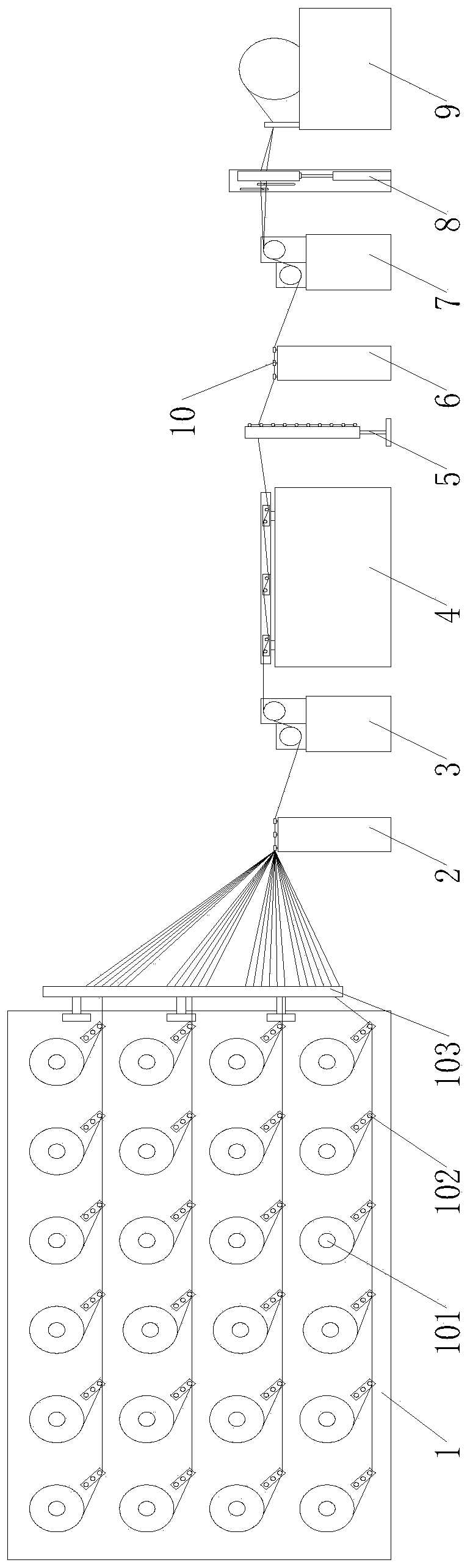

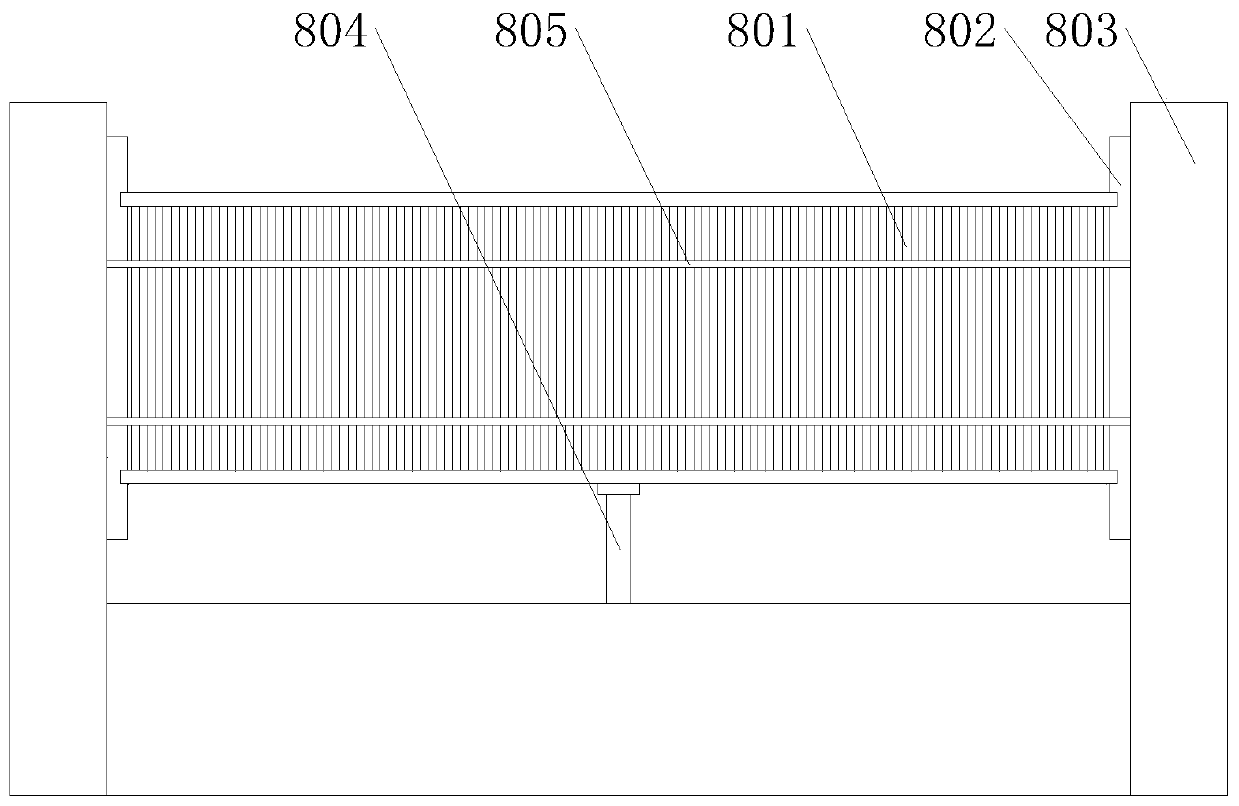

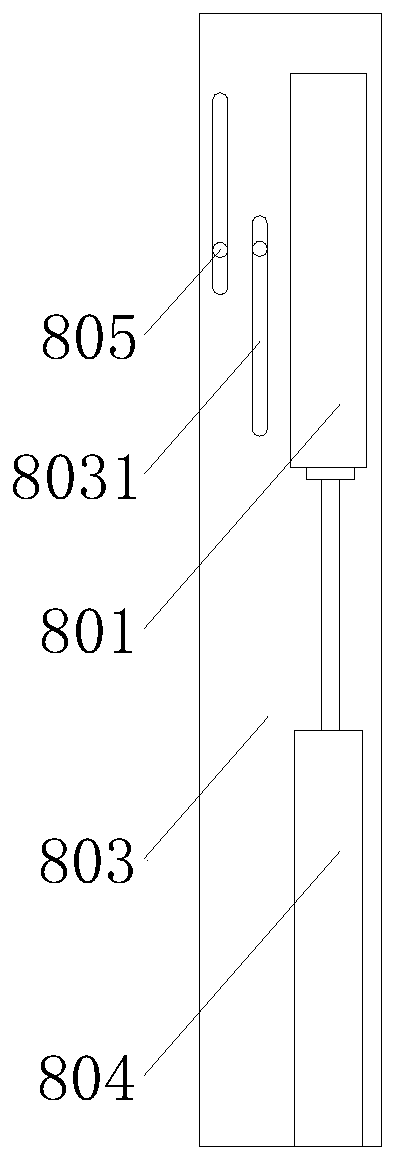

[0030] ②A plurality of mother yarn spindles are respectively placed on multiple fixed rollers on both sides of the electronically controlled spindle frame, and the electromagnetic speed-regulating motor at one end of the fixed roller drives the mother yarn spindles to carry out the yarn output work. Pass through the rectangular hole of the threading frame, so that each mother yarn is independent of each other a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com