Preparation method of polyimide prepreg

A polyimide and polyimide resin technology, which is applied in the field of preparation of polyimide prepregs, can solve the problem of low preparation efficiency, and the final volatile content and viscosity control of prepregs are greatly affected by ambient temperature. and other problems, to achieve the effect of reducing porosity, realizing batch stable preparation, and improving flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

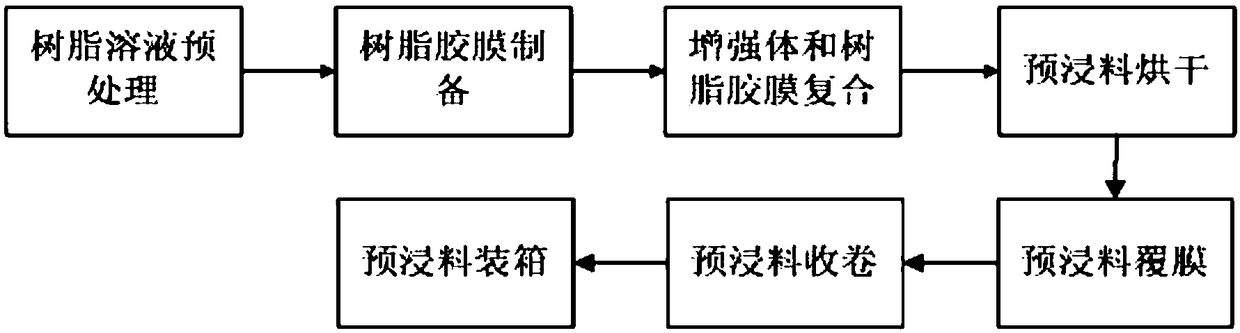

[0035] Such as figure 1 Shown, a kind of preparation method of high temperature resistant polyimide prepreg, the preparation raw material of this high temperature resistant polyimide prepreg comprises polyimide resin solution and fiber reinforcement; The steps of this method comprise:

[0036] (1) polyimide resin solution is placed in reaction ax and carries out vacuum suction filtration, removes excess solvent;

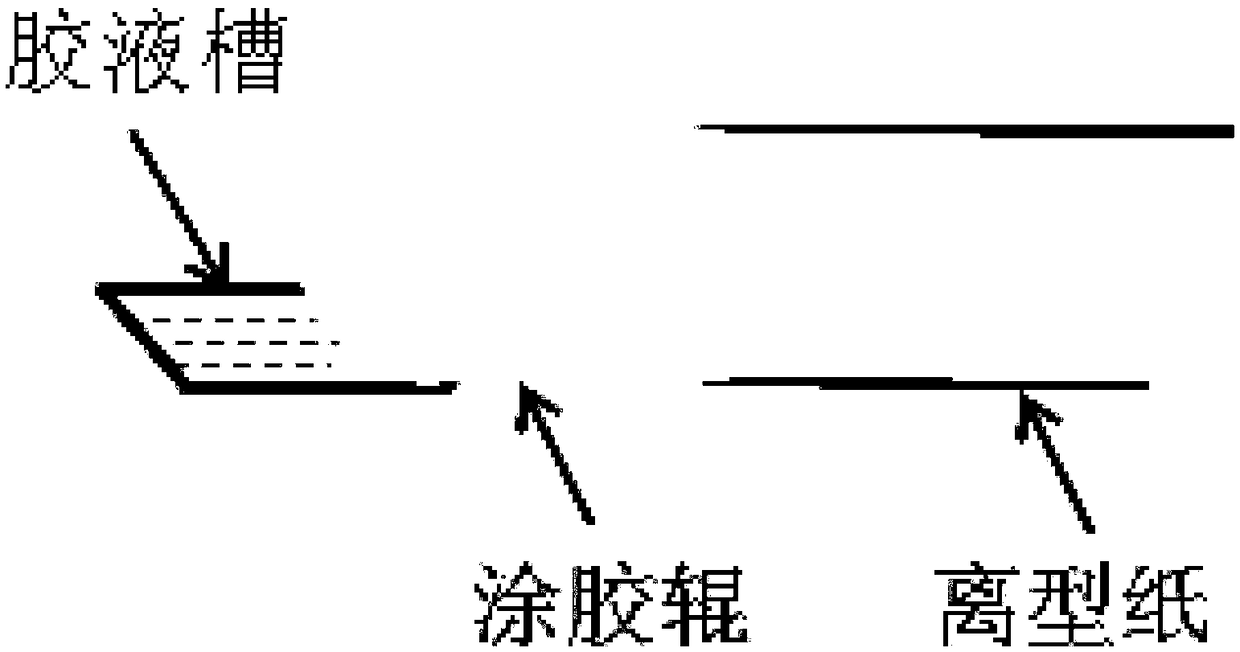

[0037] (2) the treated polyimide resin solution obtained in the step (1) is placed in the glue tank, and adopts casting process, the polyimide resin solution is evenly coated on the release paper, polyimide The imide resin solution forms a polyimide resin film on the release paper;

[0038] (3) pulling the fiber reinforcement to the top of the polyimide resin film in step (2) by a set tension, and impregnating the polyimide resin film into the fiber reinforcement through a pressure roller;

[0039] (4) drying the product obtained in step (3) through the drying tunn...

Embodiment 1

[0066] The prepreg is prepared by using unidirectional carbon fiber reinforced PMR type 906 resin. Firstly, the 906 polyimide resin solution with a solid content of 50wt% is placed in the reaction axe. The temperature of the reaction kettle is set at 40°C. After 1.07, take out the resin glue and pour it into the glue tank, and use the double-roller meshing casting process to evenly coat the resin solution in the glue tank on the release paper, and adjust the gap between the two rolls to 0.37mm. The arranged carbon fiber tow is drawn to the top of the resin glue film under the tension of 260N, and the pressure of 0.05MPa is applied by the pressure roller to realize its impregnation, and then the prepreg is passed through the temperature at a uniform speed of 2.5m / min. Dry in a drying tunnel set at 70°C to remove excess solvent. After passing through the drying tunnel, the surface of the prepreg is covered with a film. The surface isolation film is pulled to the top of the prepre...

Embodiment 2

[0068] The prepreg is prepared by unidirectional carbon fiber reinforced PMR type 906 resin. Firstly, the 906 polyimide resin solution with a solid content of 50wt% is placed in the reaction axe. After 1.05, take out the resin glue and pour it into the glue tank, and use the double-roller meshing casting process to evenly coat the resin solution in the glue tank on the release paper, and adjust the gap between the two rolls to 0.38mm. The arranged carbon fiber tow is pulled to the top of the resin glue film under the tension of 260N, and the pressure of 0.05MPa is applied by the pressure roller to realize its impregnation, and then the prepreg is passed through the temperature setting at a uniform speed of 2m / min. Dry in a drying tunnel set at 70°C to remove excess solvent. After passing through the drying tunnel, the surface of the prepreg is covered with a film. The surface isolation film is pulled to the top of the prepreg under the action of a tension of 150N, and applied b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com