Electroplating film supplying device for automatically adjusting tension of sticking film

An automatic adjustment and supply device technology, which is applied in the field of electroplating film supply devices, can solve the problems of difficulty in controlling the tension of the film, reducing production efficiency and product qualification rate, etc., and achieves the effect of convenient tension control, improving production efficiency and product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

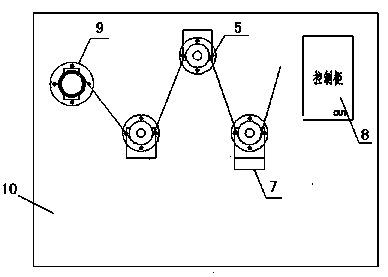

[0010] Such as figure 1 As shown, an electroplating film supply device capable of adjusting the tension of the film, the device includes a frame 10, a film unwinding device fixed on the frame 10, and several guide rollers 5 that are distributed up and down in dislocation, and the device also includes a control cabinet 8, The film sticking unwinding device includes a tensioner 9 and a magnetic powder clutch 4 connected with the tensioner 9. A torque sensor 7 is arranged on the one guide roller, and the torque sensor 7 and the magnetic powder clutch 4 are connected with the control cabinet 7 for signals. There are three guide rollers 5, which are fixed on the frame in a triangle shape.

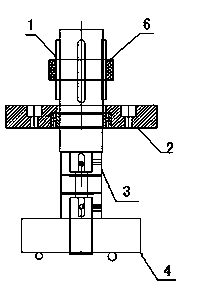

[0011] Tensioner 9 such as figure 2 As shown, it includes a film sticking roller shaft 1 and a fixed film sticking shaft shaft 1 and a film sticking shaft seat 2, and the film sticking shaft seat 2 is provided with countersunk screw holes for fixing on the machine plus 10. The input end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com