Direct-current brush gear motor

A deceleration motor, DC brush technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems affecting the service life of the reducer, abnormal collision noise, etc., to improve the starting response speed, service life and convenience sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

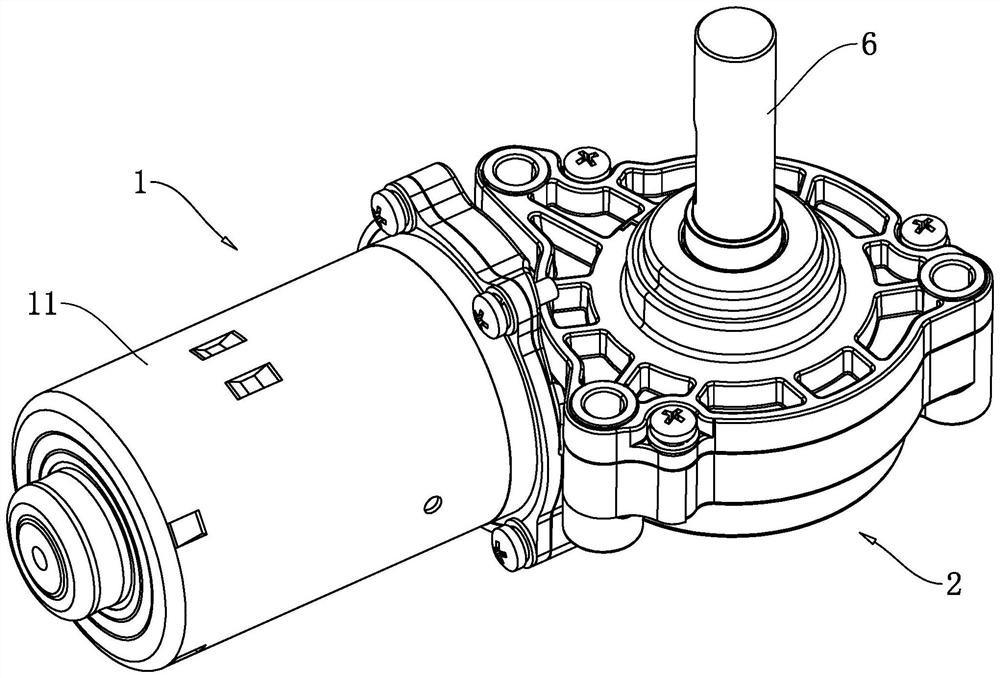

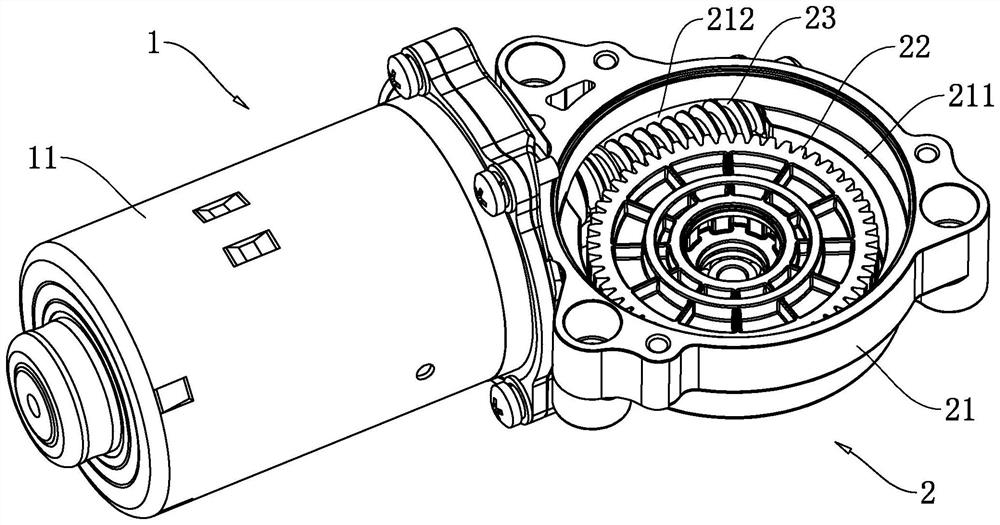

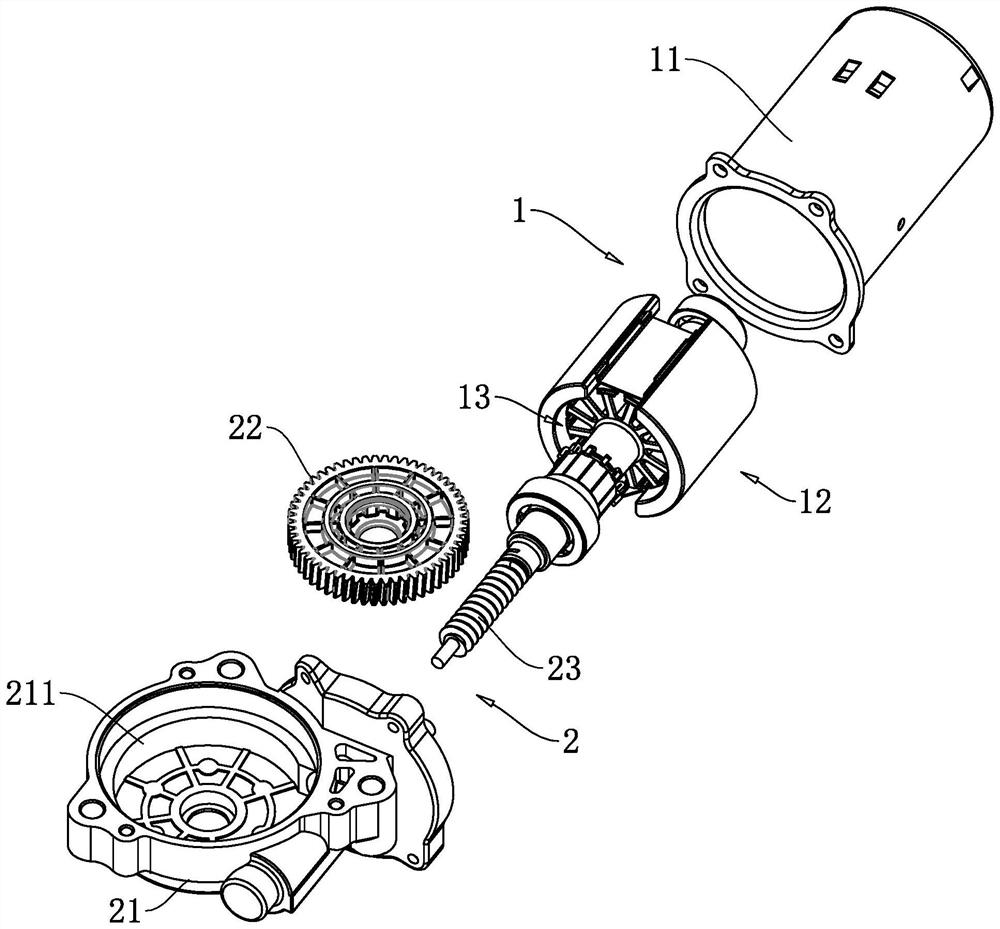

[0043] The embodiment of the present application discloses a DC brushed deceleration motor. refer to figure 1 , figure 2 and image 3 , a DC brush deceleration motor includes a drive motor 1 , a deceleration mechanism 2 and an output shaft 6 . The drive motor 1 includes a casing 11 and a stator 12 and a rotor 13 installed in the casing 11, and the deceleration mechanism 2 includes a casing 21, a worm gear 22 and a worm 23; the casing 11 is bolted to one side of the casing 21, The box body 21 is provided with a first installation cavity 211 for installing the worm 23 and a second installation cavity 212 for the worm 23 to be installed. The first installation cavity 211 and the second installation cavity 212 communicate with each other. The worm wheel 22 is located in the first installation cavity 211 and is rotatably connected with the box body 21 , the worm 23 is passed through the second installation cavity 212 of the box body 21 , the worm wheel 22 is engaged with the wo...

Embodiment 2

[0055] refer to Figure 9 and Figure 10 The difference between the embodiment of the present application and the embodiment 1 is that: the box body 21 is provided with a center distance fine-tuning mechanism 5, and the center distance fine-tuning mechanism 5 includes a mounting seat 51, a mounting ring 52, a third bearing 53 and an adjusting bolt 54, A connecting groove 214 is defined on the inner wall of the second mounting cavity 212 , the mounting seat 51 is fixed in the connecting groove 214 , and a circular through hole is defined in the center of the mounting seat 51 . The mounting ring 52 is located in the port, and the mounting ring 52 is coaxially arranged with the port. A fine-tuning gap 55 is formed between the outer wall of the mounting ring 52 and the inner wall of the port, and the fine-tuning gap 55 is 1.5mm-2.5mm. , the fine adjustment gap 55 is set to 2mm. An elastic connecting block 56 is connected between the mounting ring 52 and the mounting seat 51 , th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com