Permanent magnetism biased radial magnetic bearing in external rotor

A technology of permanent magnetic bias and external rotor, applied in the direction of bearings, shafts and bearings, shafts, etc., can solve the problems of severe coupling, large excitation current, multi-magnetomotive force, etc., so as to ensure the stability of operation and reduce the axial Size, effect of saving control circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

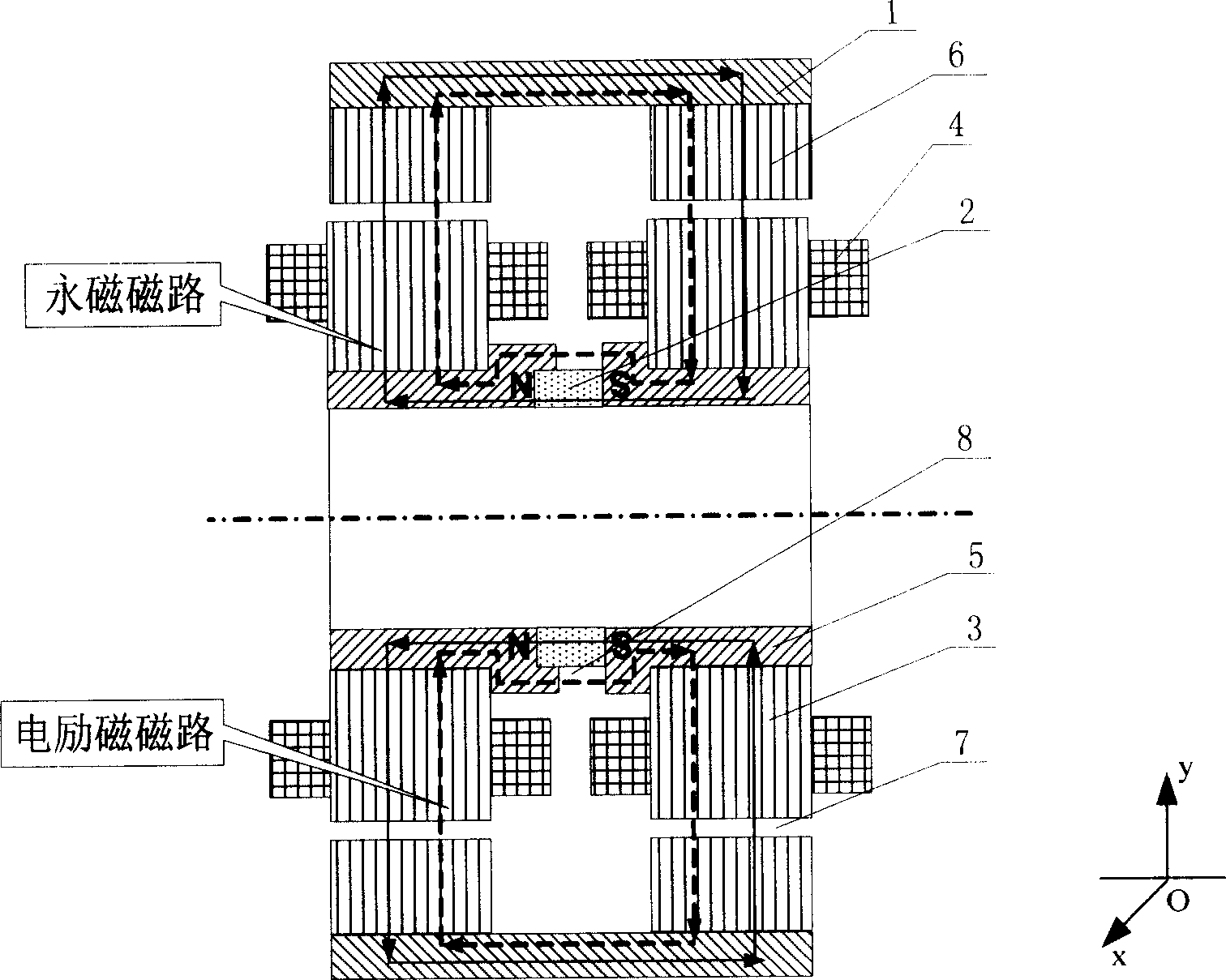

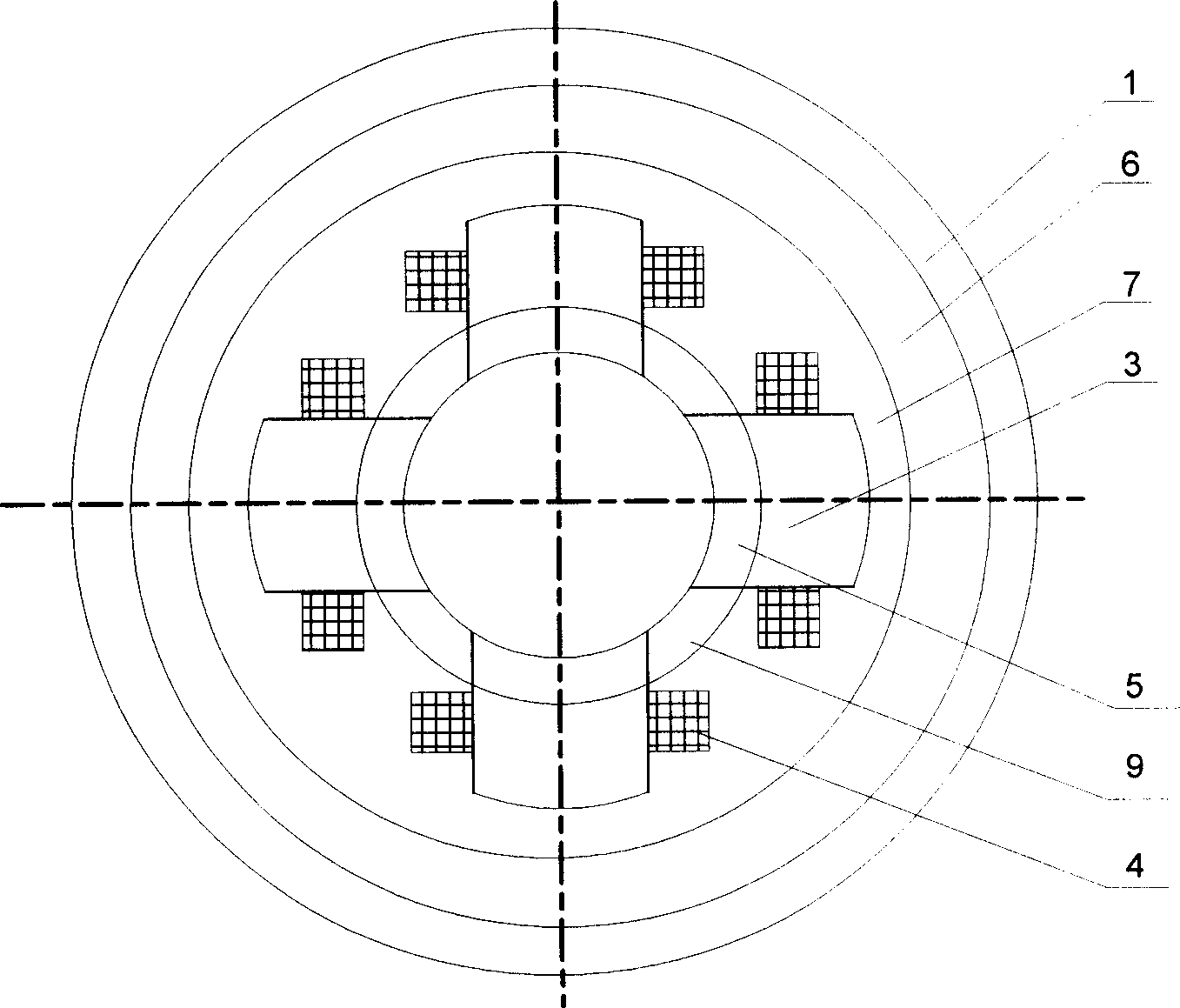

[0010] Such as figure 1 , 2 As shown, the present invention consists of 1 outer magnetic guide ring 1, 1 permanent magnet 2, 8 stator cores 3, 8 inner spacer magnets 9, 8 excitation coils 4, 8 inner guide magnets 5, 2 rotors 6 iron cores, 4 stator cores 3 form 4 stator poles in the X and Y directions, 8 stator cores 3 form the stator poles in the X and Y directions at the left and right ends of the magnetic bearing, and 8 inner spacer magnets 9 connect The stator core 3 at the left and right ends of the magnetic bearing in the X and Y directions, each stator pole is wound with an excitation coil 4, the outside of the stator core 3 is the rotor core 6, the outside of the rotor core 6 is the outer magnetic ring 1, and the inside of the rotor core 6 There is a certain gap between the surface and the outer surface of the stator core 3 to form an air gap 7. The permanent magnet 2 is located between the inner magnets 5, and a second air gap 8 is formed between the inner magnets 5 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com