Automatic tightening device of belt conveyor

A technology of automatic tensioning device and belt conveyor, which is applied in the direction of conveyor, transportation and packaging, can solve the problems of small adjustment range, decreased belt tension, system leakage, etc., and achieves stable and adjustable tensioning speed, The effect of precise tension control and guaranteed response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

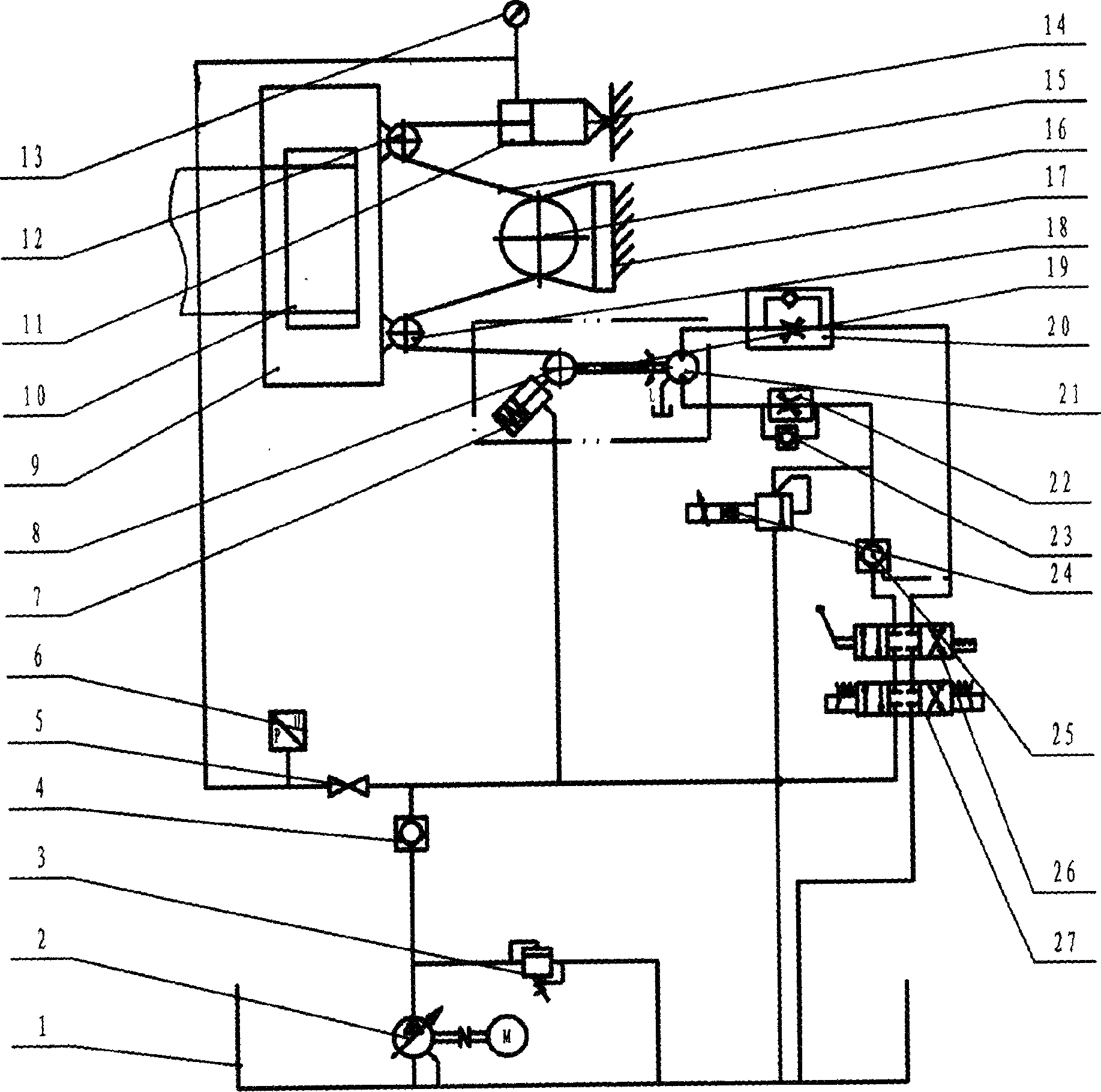

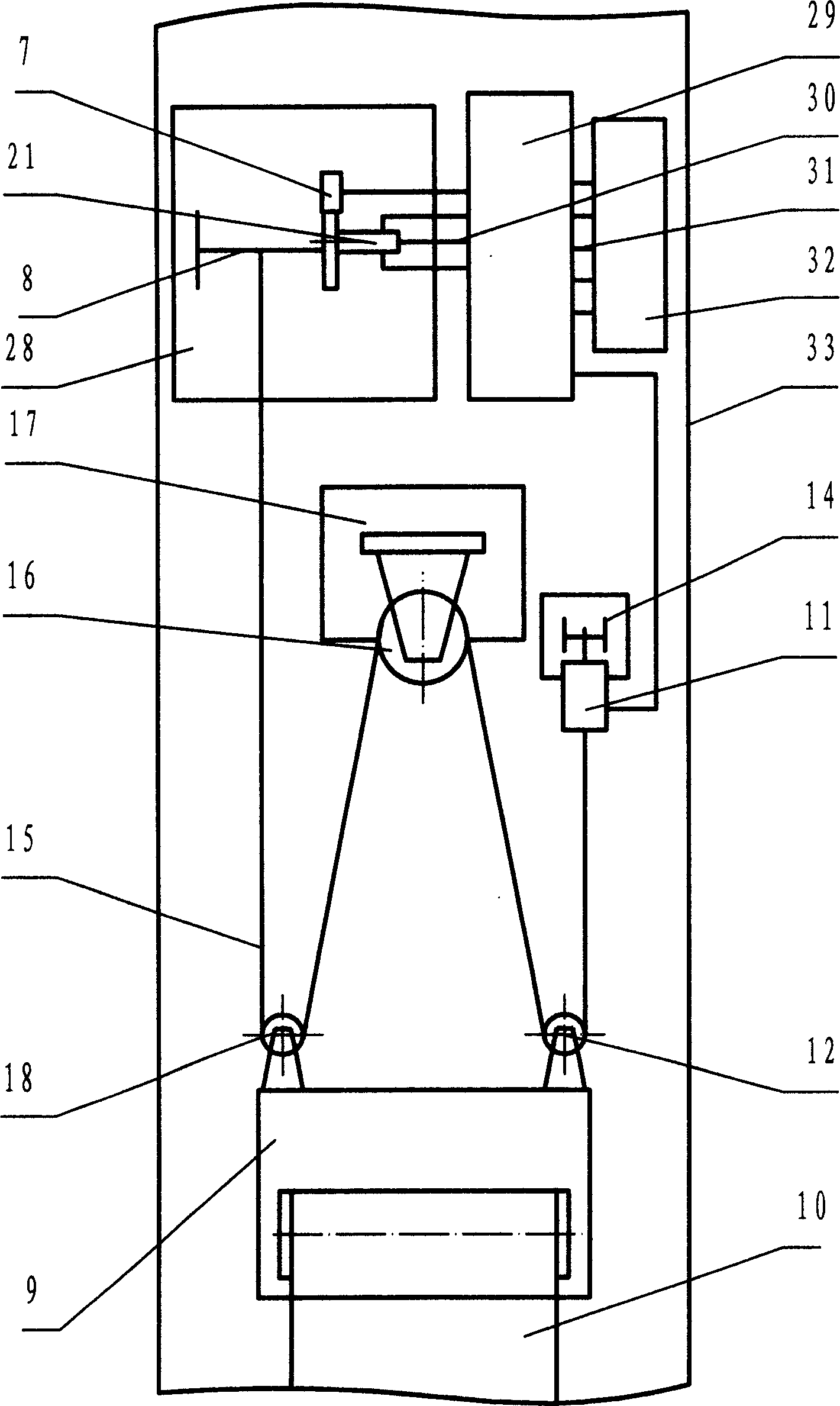

[0015] Force-measuring cylinder 11 is refitted from an ordinary single-acting piston cylinder. The oil inlet of the rodless chamber is blocked, and an air release valve is installed above the rodless chamber, while a pressure gauge joint is installed above the rod chamber. Release valve.

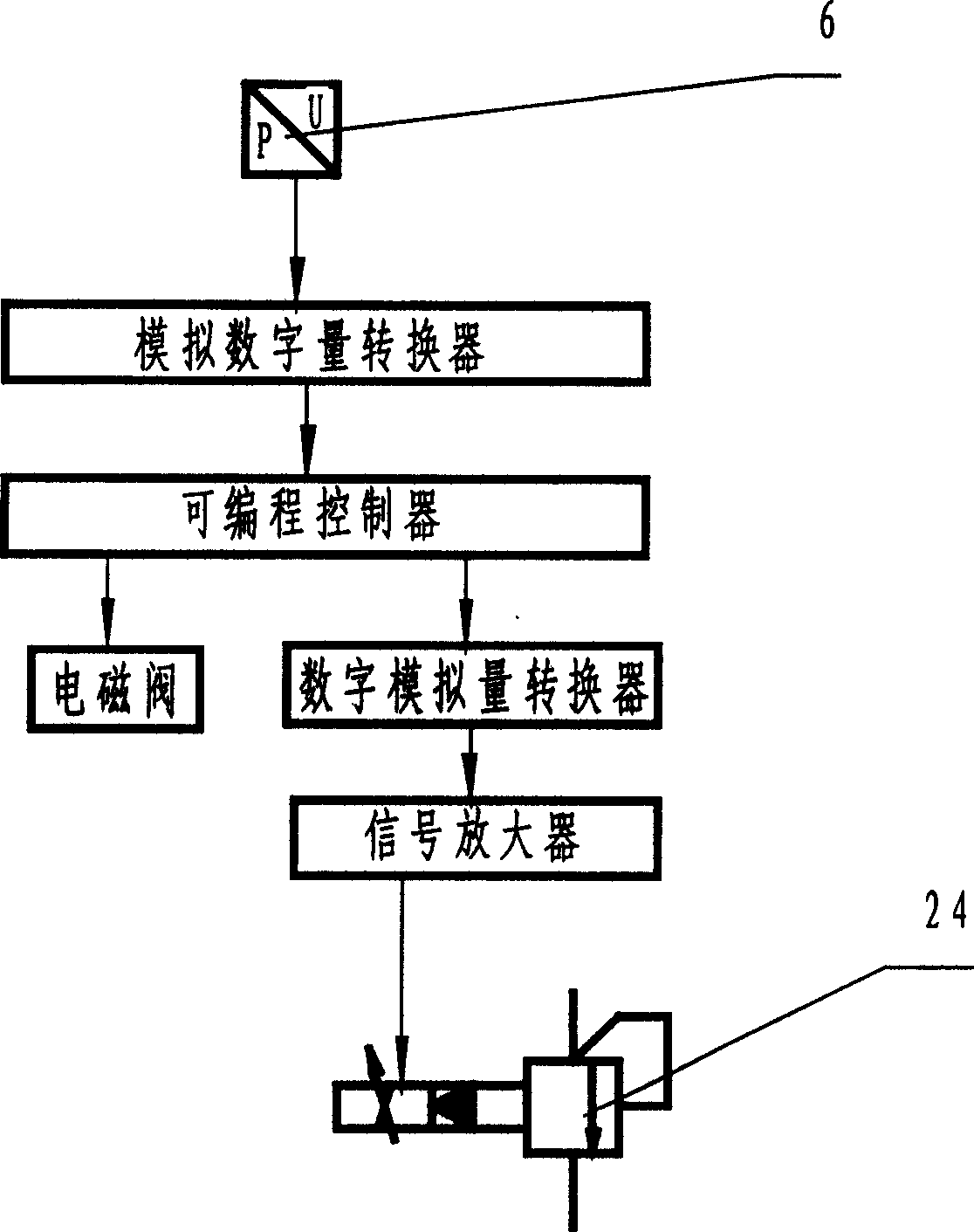

[0016] The shut-off valve 5 is connected with the oil inlet of the rod chamber of the dynamometer cylinder 11 through the pressure sensor 6, and the pressure gauge 13 is connected with the air release port of the rod chamber of the dynamometer cylinder. During belt tensioning and constant tension operation of the conveyor, the tension monitoring device provides real-time and accurate belt tension values, which are fed back to the electronic control device, and the control program controls the hydraulic device and hydraulic winch to achieve belt tensioning Precise adjustment of force.

[0017] The oil outlet of the hydraulic pump 2 is connected to the tension monitoring device, the rod cavit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com