Rolling tensioning structure for chain conveyer

A technology of chain conveyor and tensioning mechanism, which is applied in the direction of conveyor, transportation and packaging, etc. It can solve the problems of the equipment due to the chain not working normally, not being tensioned, and broken chain, so as to reduce the cost of manual maintenance and avoid runaway. The effect of deflecting and reducing the force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

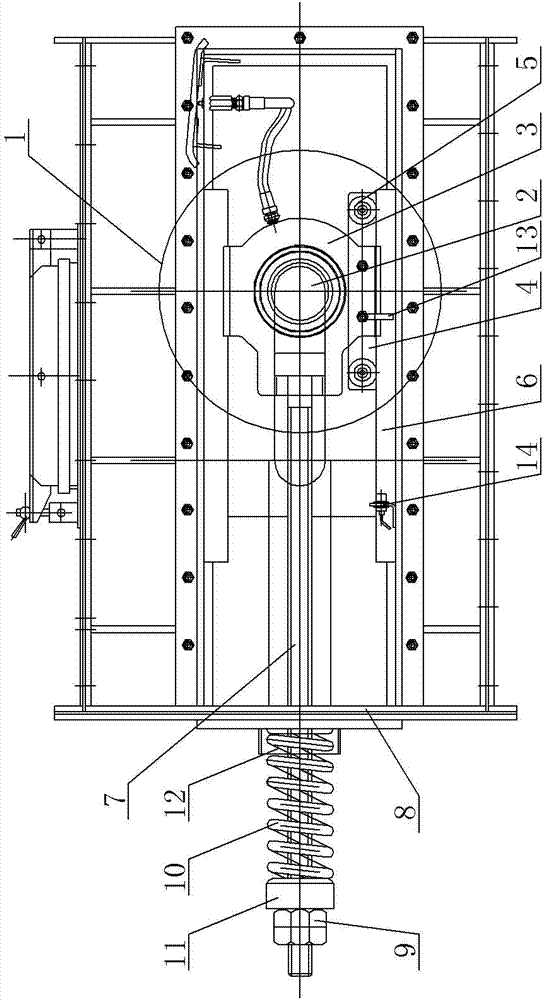

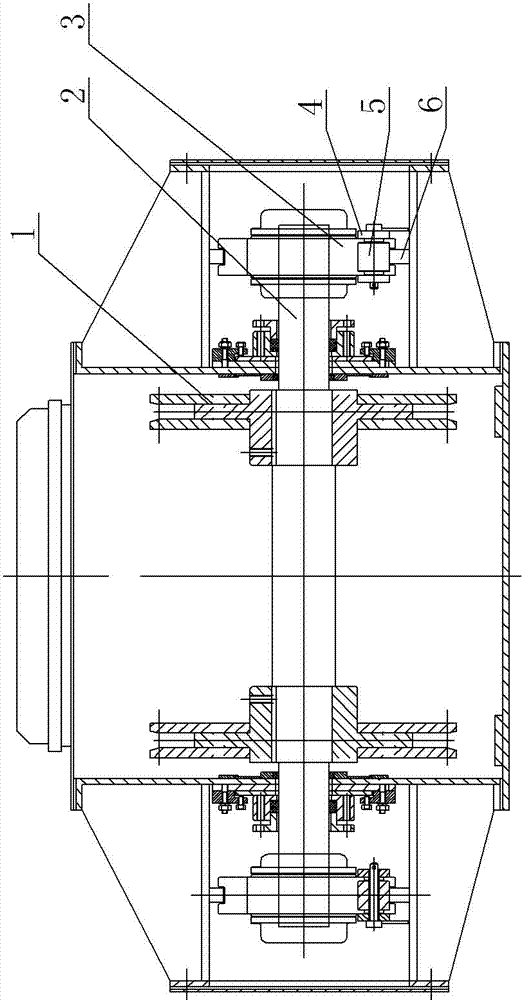

[0009] See Figure 1 ~ Figure 2 , which includes a conveying chain 1, the end of the conveying chain 1 is set on the rotating shaft 2, the two ends of the rotating shaft 2 are respectively supported on the bearing seat 3, and the two sides of the bottom of the bearing seat 3 are respectively fastened with a mounting plate 4, and the two ends of the mounting plate 4 The middle position is provided with rollers 5 respectively, and the rollers 5 are supported on the limit guide rail 6 at the bottom, and the upper part of the bearing seat 3 is fastened to one end of the adjusting screw 7, and the other end of the adjusting screw 7 runs through the support vertical plate 8 and is fitted with a Nut 9, an automatic spring 10 is arranged between the nut 9 and the outer side of the bracket vertical plate 8, the automatic spring 10 is set on the adjusting screw rod 7, the inner side of the nut 9 is equipped with a guide washer 11, and the outer side of the bracket vertical plate 8 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com