Control system for bolt fastening device

A bolt fastening device and control system technology, which is applied to electrical program control, program control in sequence/logic controllers, screwdrivers, etc., can solve the problems of difficult control of bolt installation quality, reduced efficiency of on-site installation, and heavy workload of on-site personnel and other problems, to achieve the effect of shortening assembly time, reducing labor intensity and improving fastening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to enable those skilled in the art to better understand the present invention, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

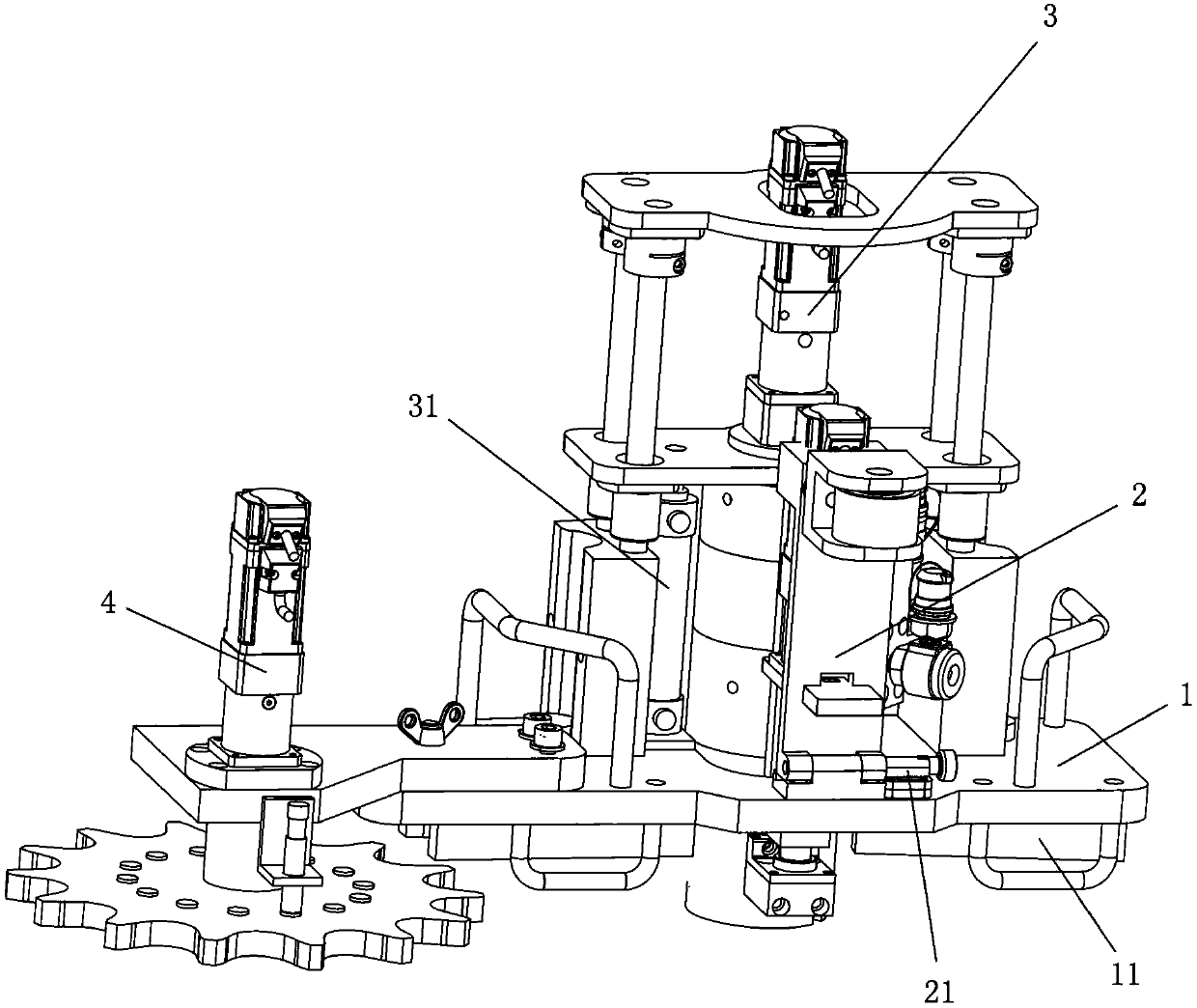

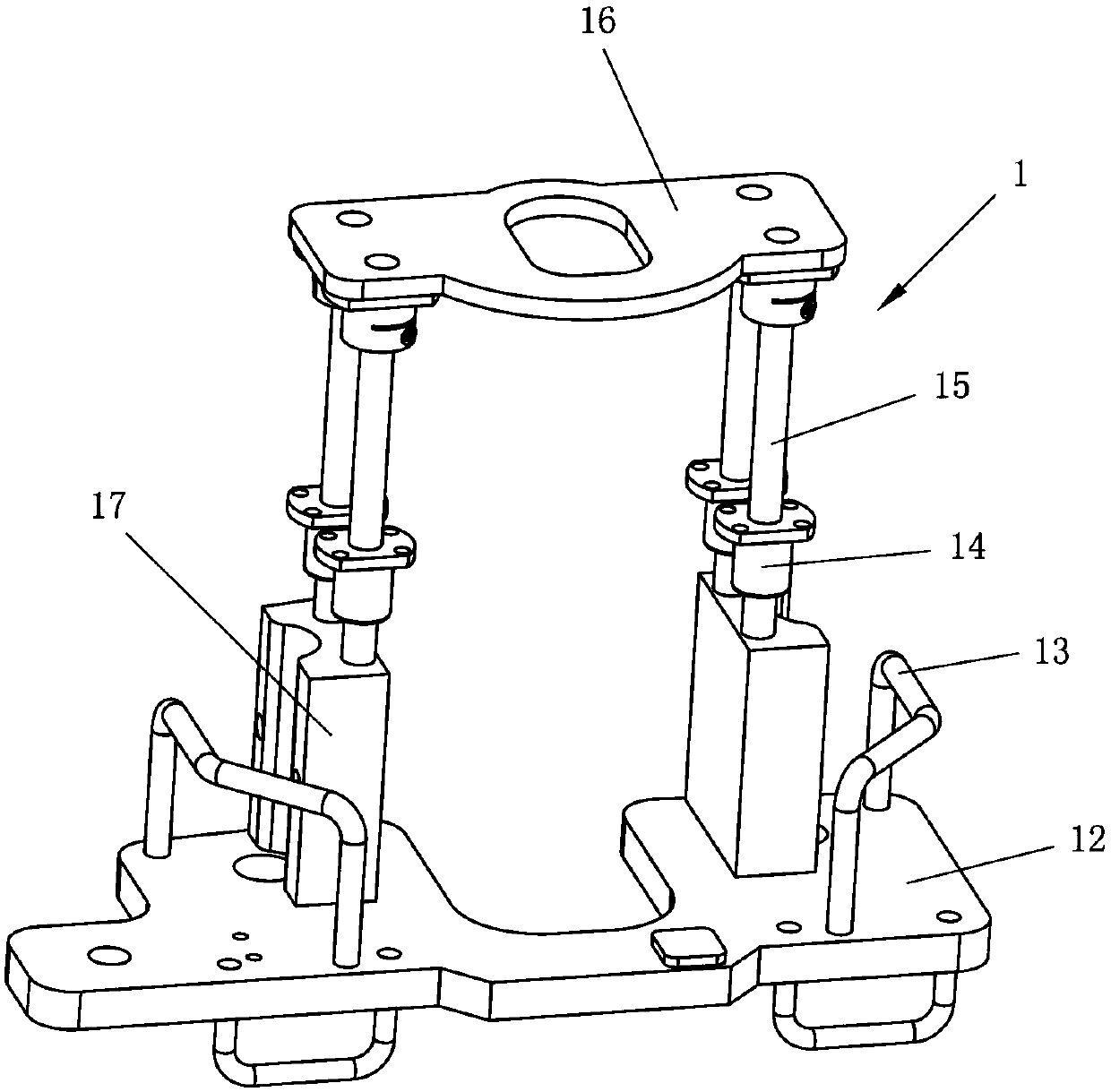

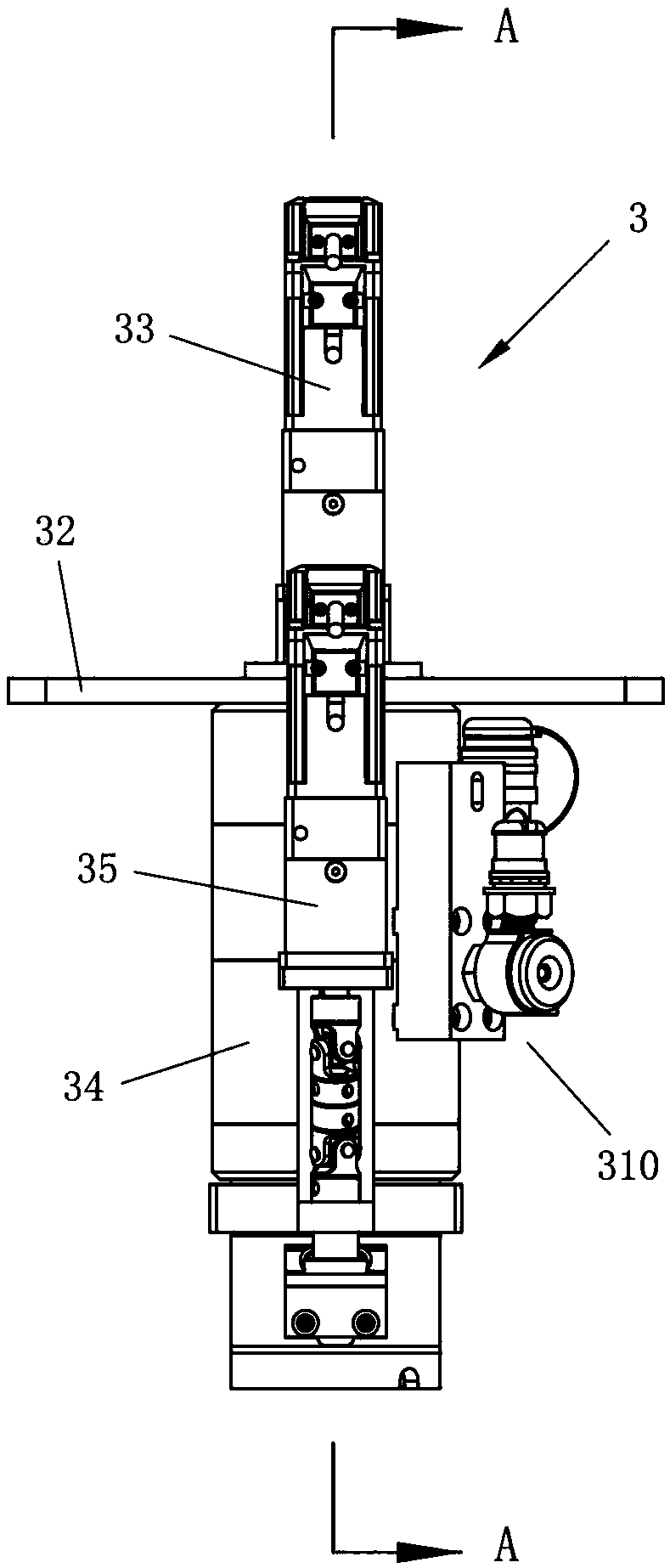

[0041] refer to figure 1 , shows a bolt fastening device according to an embodiment of the present invention, the bolt fastening device is used to fasten manually pre-tightened bolts to a predetermined torque value to realize the connection between components. The applied plurality of bolts may be arranged in various regular ways, for example, may be arranged in a straight line, or arranged in an arc or in a circumferential direction. The bolt fastening device provided by the present invention may include a support 1, an execution unit 3 and a travel unit 4 installed on the support 1, and a control system for controlling the operations of the execution unit 3 and the travel unit 4, the execution unit 3 is used The bolts are stretched in the vertical direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com