All-in-one machine for chipless cutting of plastic pipes

A plastic pipe and cutting machine technology, applied in metal processing, etc., can solve the problems of high acceleration, double-out plastic pipe traction and cutting can not achieve synchronization, etc., to achieve the effect of ensuring stability and realizing synchronization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

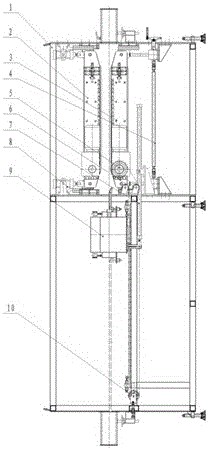

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

[0013] The present invention produces plastic pipe pulling machine and cutting machine such as figure 1 As shown, the upper crawler, the lower crawler and the cutting machine are respectively fixed on the frame. The upper crawler realizes the compression and loosening of the pipe through the compression assembly, and the height of the lower crawler can be adjusted through the lifting assembly to adapt to the production of pipes of different specifications. Ensure that the traction center and the center of the cutting machine are in a straight line. The synchronous sprocket is equipped with an adjustment clutch and installed on the lower track. The synchronous sprocket is connected with the cutting machine through a synchronous chain. When the cutting signal is detected, the return cylinder starts to give The instantaneous forward thrust of the cutting machine instantly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com