A winch and its traction angle adjustment method

An adjustment method and a traction angle technology, which can be applied to the hoisting device, the mechanism of the mainspring, etc., can solve the problems of low operation efficiency, automatic change of the traction angle, etc., and achieve the effect of improving the operation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

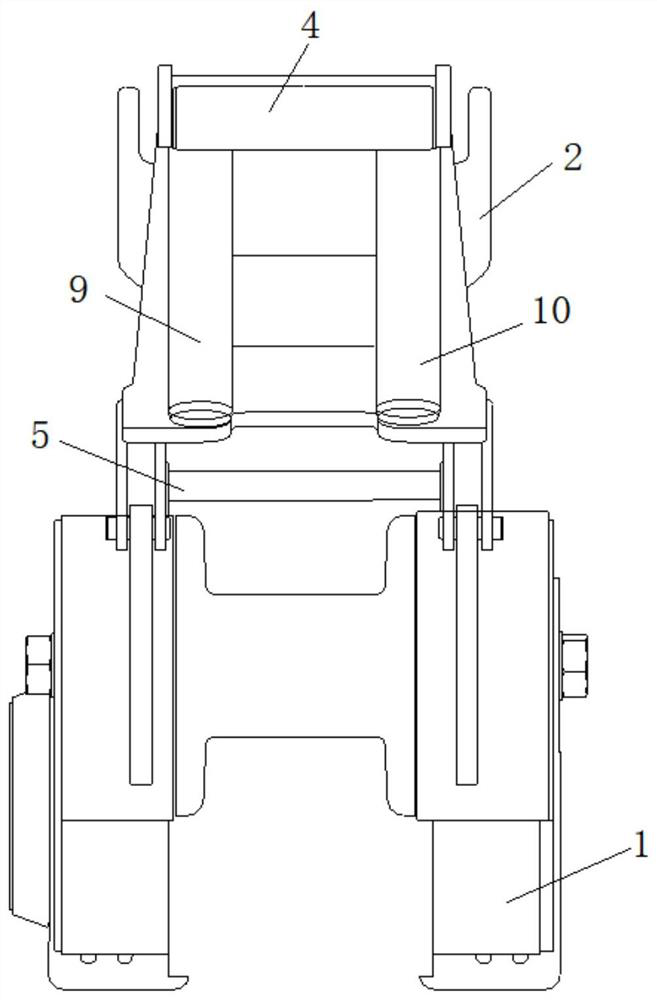

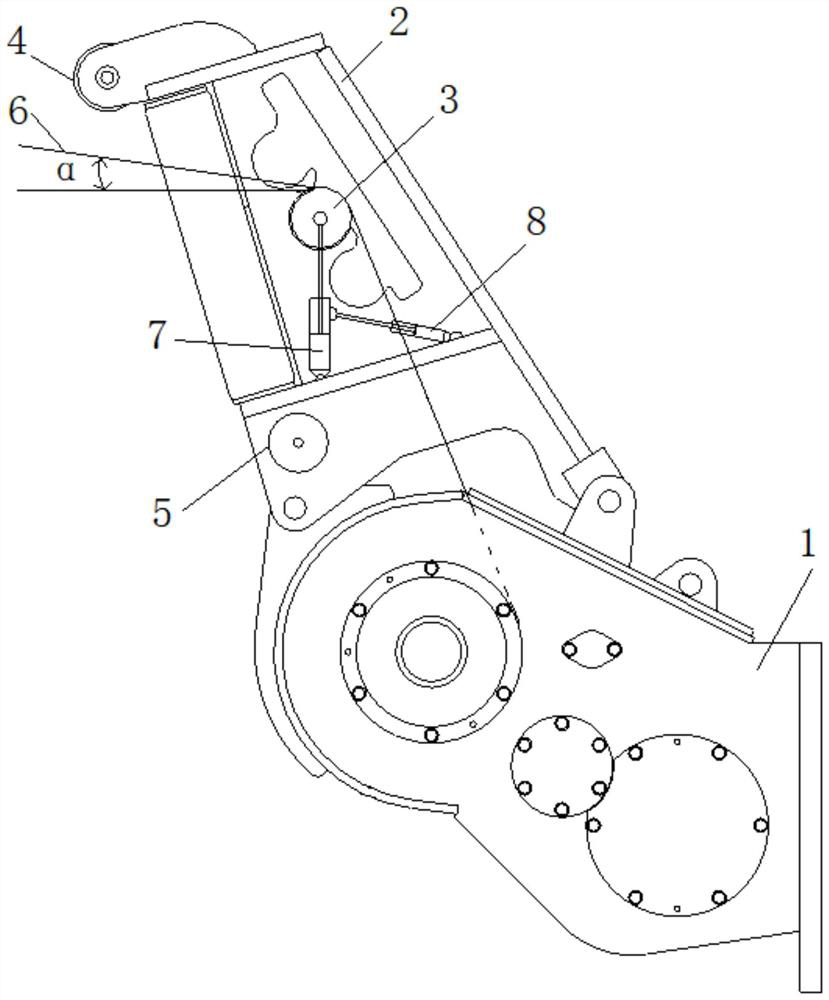

[0036] figure 1 is the front view of the winch provided in this embodiment, figure 2 is a side view of the winch provided in this embodiment, such as figure 1 with figure 2 As shown, this embodiment provides a winch, also known as a winch, which is a light and small lifting and traction device for lifting or pulling heavy objects, and is mainly used in construction, water conservancy projects, gardens, mines, docks and other scenarios to realize The lifting or flat dragging of materials can also be used as supporting equipment on the electronically controlled automatic operation line.

[0037] The winch includes a winch box 1, a reel (not shown), a central guide wheel 3, a first limiting wheel 4 and a second limiting wheel 5, and the winch box 1 plays a supporting role when the winch is used alone The winch can also be used as a lifting component or a traction component in other engineering machinery, such as in engineering machinery such as hoisting machinery, mine hoist...

Embodiment 2

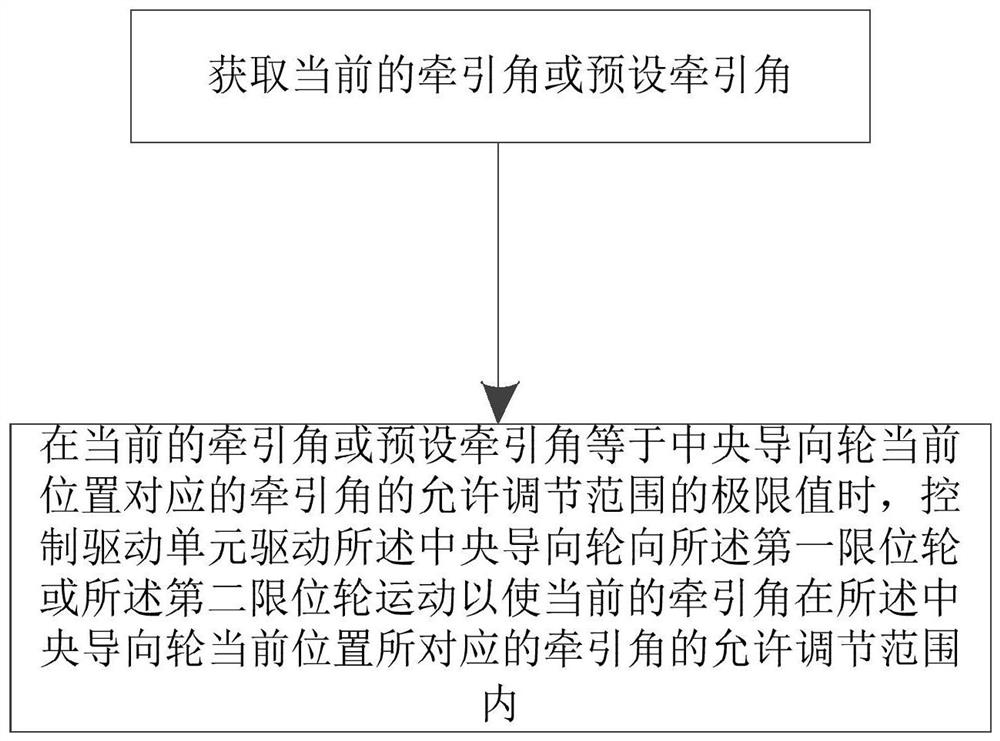

[0093] In this embodiment, the traction angle is adjusted in a continuously changing manner. Specifically, the drive unit includes two drive cylinders, and the movable end and cylinder body of each drive cylinder are respectively hinged to the central guide wheel and the guide frame, and the guide frame and the central guide Wheel sliding fit, such as slide rails and chute, etc., at the same time support the central guide wheel through two driving cylinders, and drive the central guide wheel to move a unit distance each time through the control unit, so that the current traction angle corresponds to the current position of the central guide wheel within the allowable adjustment range of the traction angle.

[0094] Of course, compared with Embodiment 1, the central guide wheel in this embodiment is only supported by two driving cylinders, and the stability is poor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com