Magnetic suspension for a vehicle

A magnetic levitation, vehicle technology, applied in railway vehicles, vehicle parts, motor vehicles, etc., can solve problems such as bulky and expensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0095] In this document, the terms "vertical" or "horizontal" refer to the system used. In the picture:

[0096] - identical numbers indicate identical or conceptually similar parts;

[0097] - Letters N and S indicate North or South Magnetic Pole.

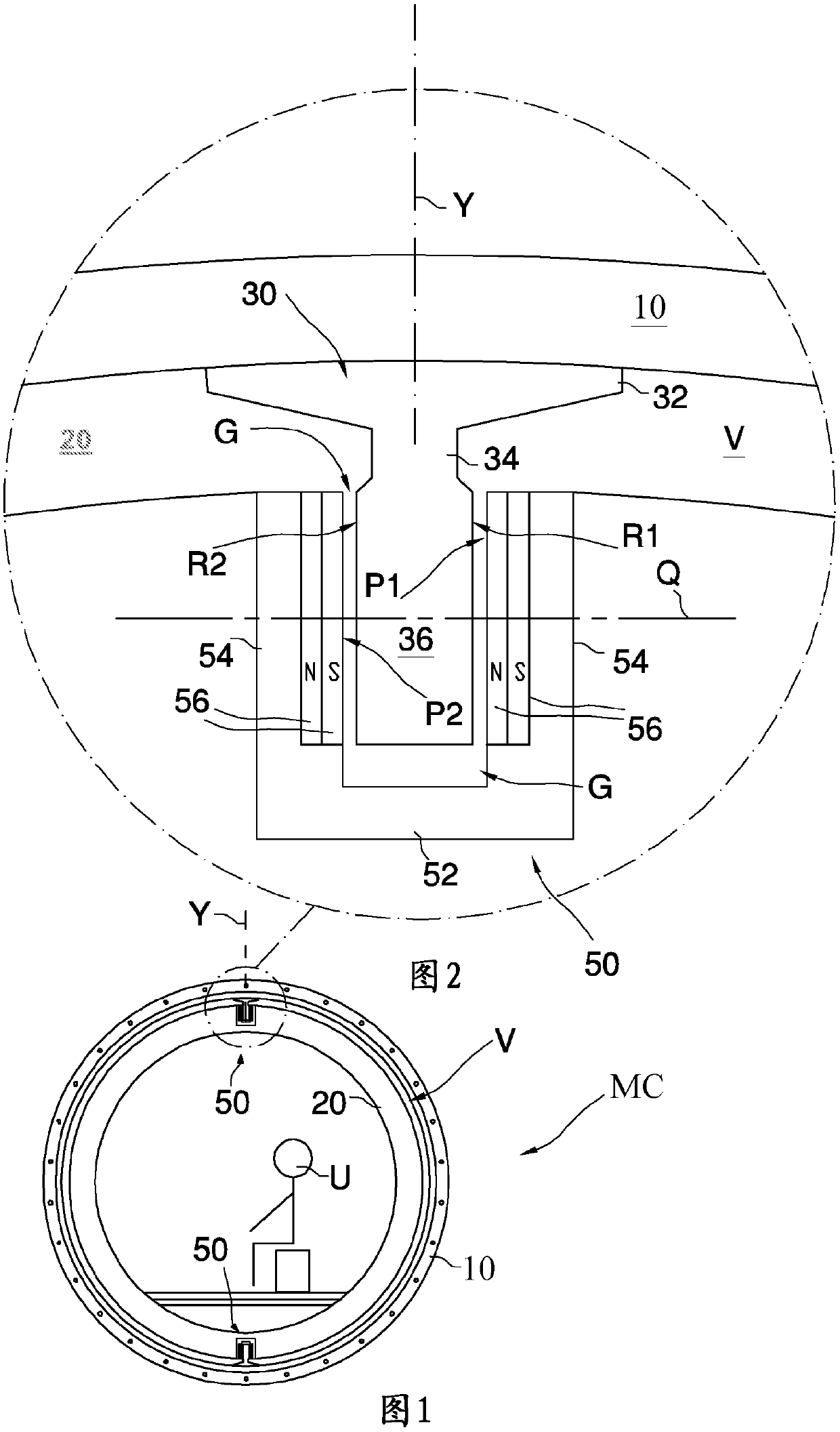

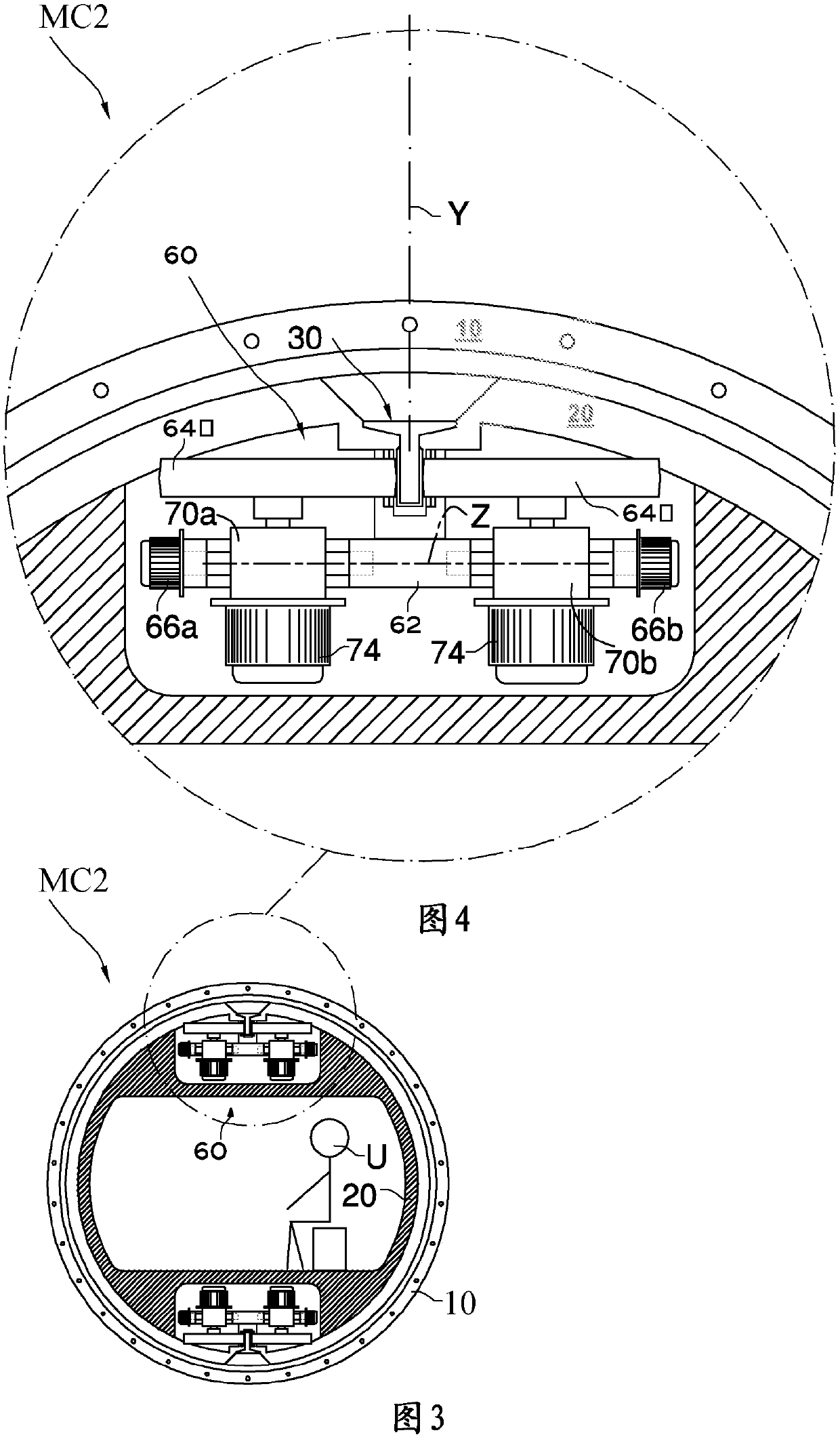

[0098] The levitation system MC for carrying a person or thing U comprises a tubular guide or structure 10 within which a cylindrical passenger compartment 20 of slightly smaller diameter is axially slid so as to maintain a gap therebetween. V.

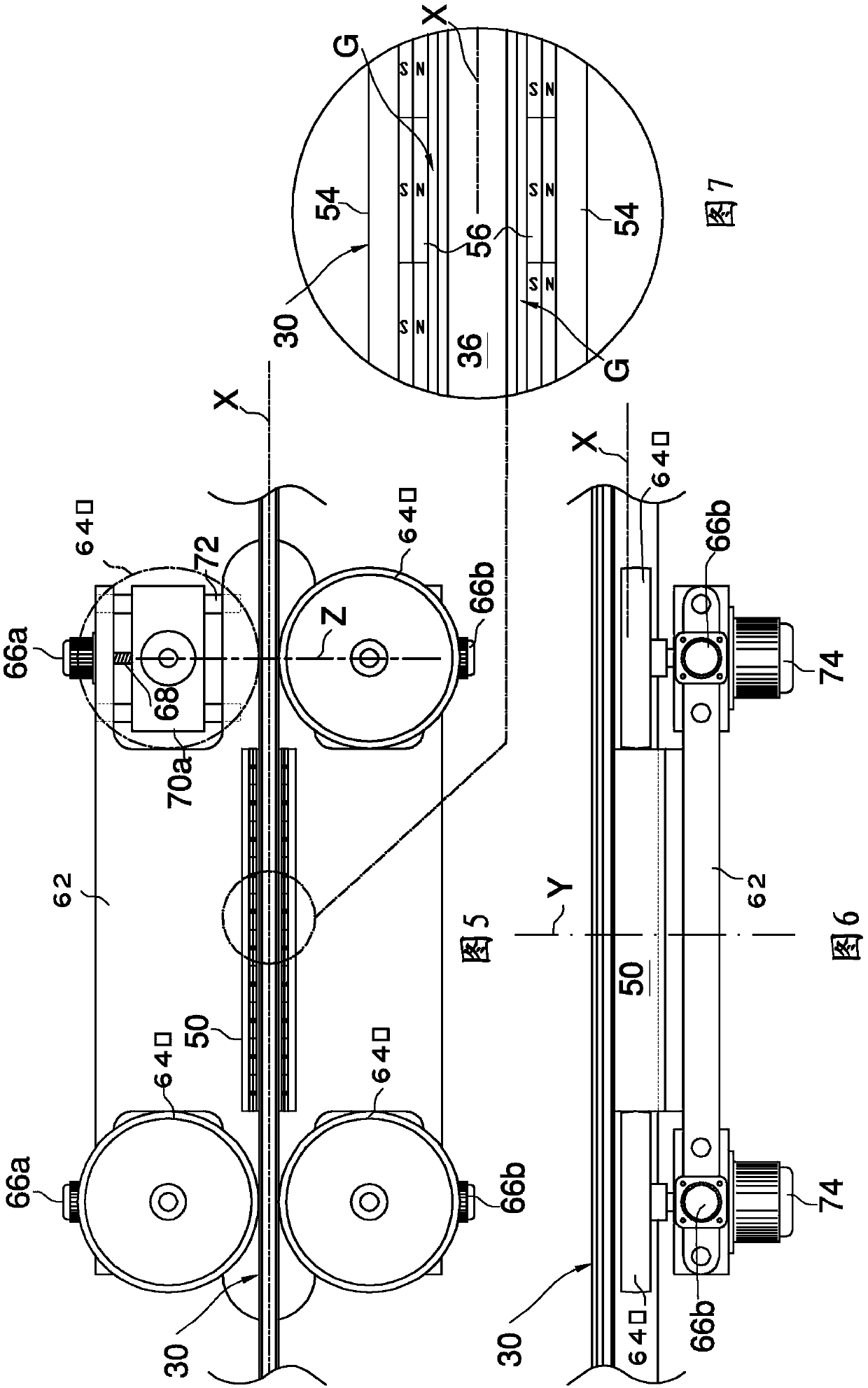

[0099] At the top of the guide 10, a track 30 ( figure 2 ), the track 30 is slidably engaged with the magnetic slideway 50 installed on the passenger compartment 20 . The rail 30 includes a flange 32 intended to cooperate with the guide 10 from which a vertical neck 34 bearing a guide head 36 protrudes. The guide head 36 has a substantially rectangular cross-section, so that it comprises two main side surfaces R1 , R2 opposite to each other.

[0100] The slideway 50 is installed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com