Master-slave control system for automatically tensioning winch mooring rope of anchor moored positioning system

A mooring positioning and control system technology, applied in anchoring arrangements, ship components, ships, etc., can solve the problems of complex master-slave control system, high cost, poor stability, etc., and achieve simple internal logic operation and data processing, external input and output. Less, the effect of simple control system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

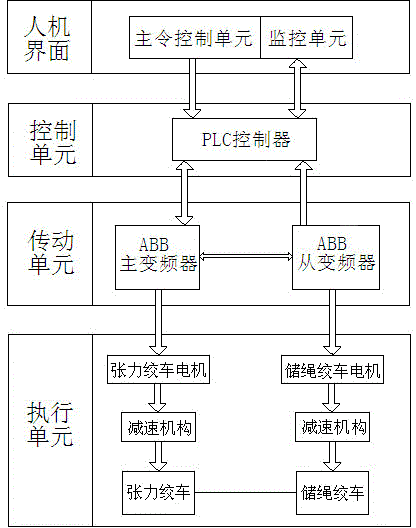

[0017] In the anchoring positioning system, the positioning winch is the key equipment to achieve anchoring positioning. The positioning winch in this system includes a tension winch and a storage winch, wherein the tension winch and the storage winch are connected by a wire rope, and the tension winch and the storage winch The steel wire rope may undergo flexible deformation. As a power winch for retracting and unwinding cables, the tension winch is a double-drum friction winch; the capacity of the tension winch to accommodate the wire rope is limited, and it is necessary to use the storage winch to help the tension winch store the wire rope, so the drum of the tension winch and the drum of the storage winch must be kept Synchronous action, so as to realize the orderly winding of the wire rope. At the same time, if there is no certa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com