Welding system for tablets

A flake and welding technology, applied in the field of welding devices, can solve the problems affecting the durability of the anvil roll, reduce the speed of the production line, reduce the productivity, etc., and achieve the effect of ensuring the welding effect, improving the reliability and guaranteeing the welding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] By referring to the accompanying drawings, the following embodiments are described, so that the present invention can be clearly understood, but the embodiments and the drawings are only for illustration and description, and should not be used to limit the protection scope of the present invention. The protection scope of the present invention is determined by the claims.

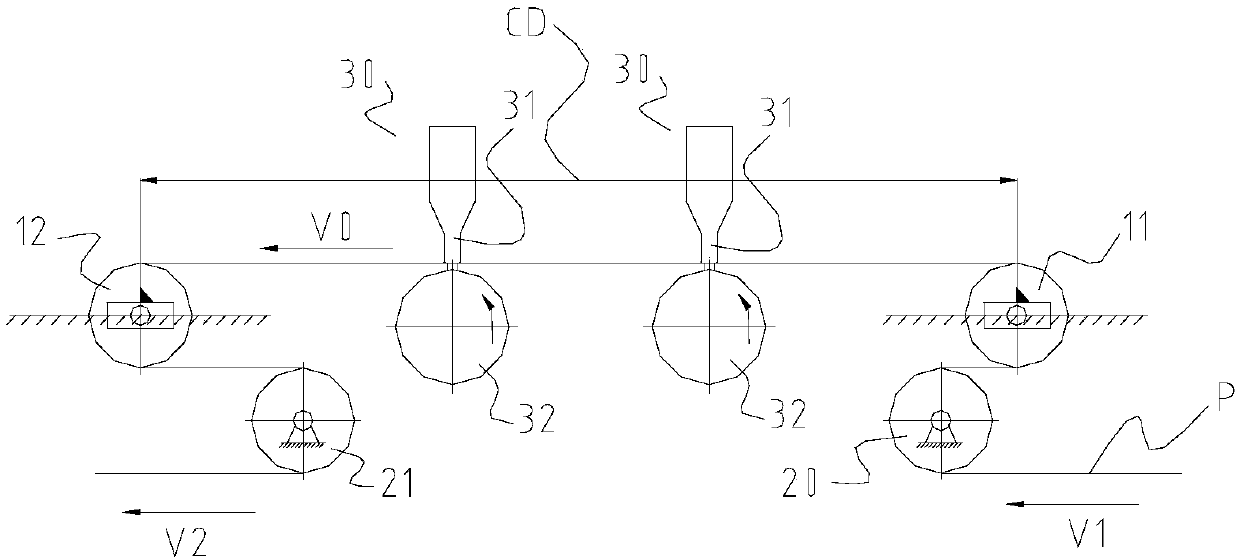

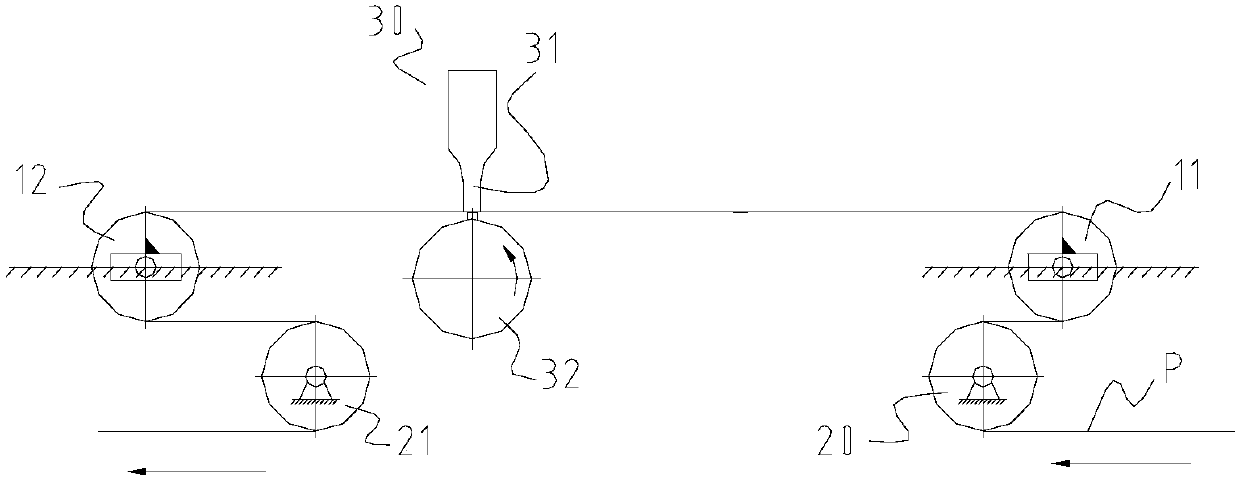

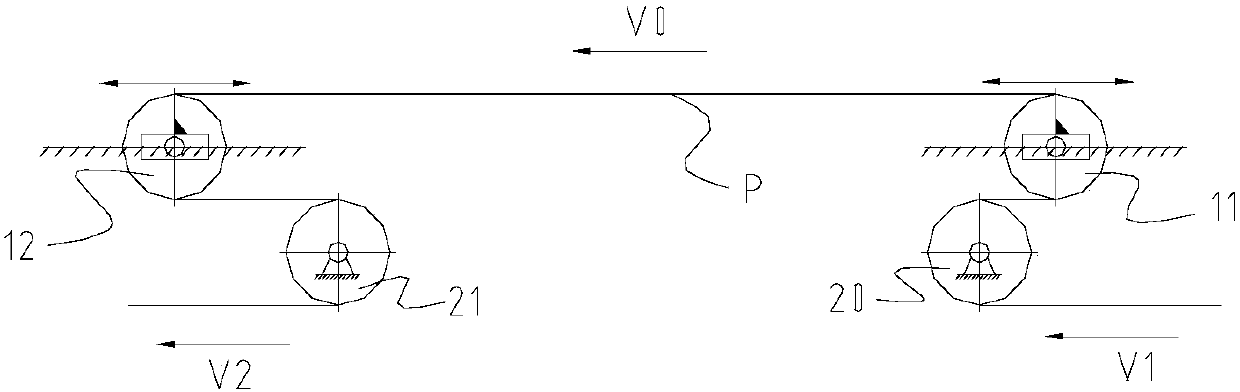

[0060] Please also refer to Figures 1 to 9 , a welding system for sheets, which has: an ultrasonic welding device 30 for applying vibration energy to the position to be welded of sheets P to weld each other; and for increasing or decreasing the conveying speed V of sheets P 0 The transport speed V at which the sheet is introduced into the transmission 1 and the conveying speed V derived from the speed changer 2 Equivalent variator 100.

[0061] Wherein, the transmission device 100 has: a first floating roller 11 that receives the sheet P sent from upstream, a second floating roller 12 that sends ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com