Setup method and arrangement for printing machine

一种调整装置、印刷机的技术,应用在印刷机、打印装置、印刷机械的通用零件等方向,能够解决输送系统维护需时等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

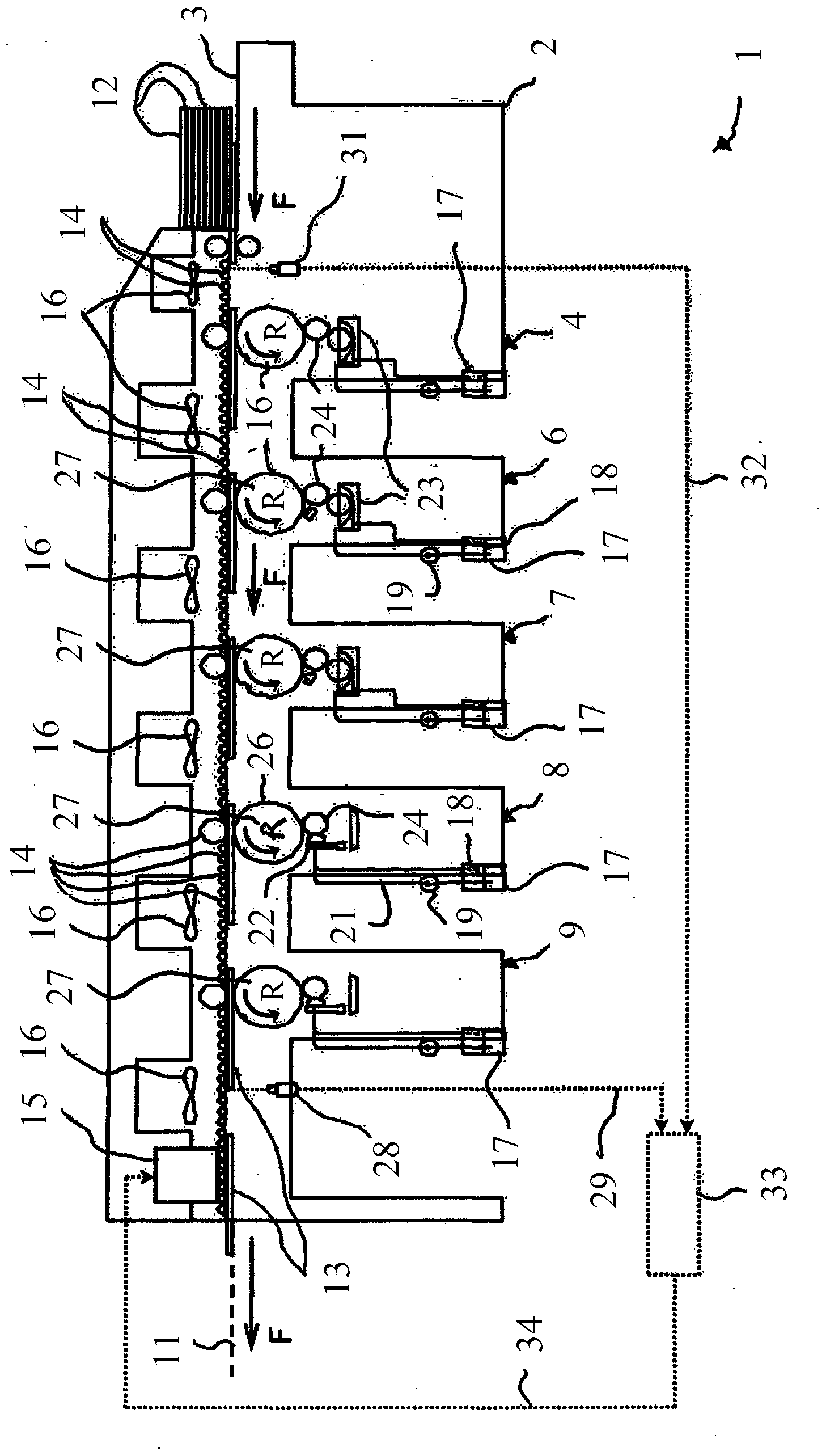

[0023] As shown in the figures, a printing machine 1 such as a flexographic printing machine comprises:

[0024] – frame 2;

[0025] – feeder or feeding station 3;

[0026] - one or more printing units, in the printing press 1 there are five consecutive printing units 4, 6, 7, 8 and 9 arranged in a row and printing five different colors such as black, blue, red, green and yellow; and

[0027] - The discharge end or delivery station 11 of the machine (shown in dotted outline).

[0028] The infeed station 3 receives a stack of board elements, for example boards 12 of unprinted corrugated cardboard, and transfers said board elements one by one to the first printing unit 4 . At the outfeed end of the machine 1 , a transfer station 11 recovers the printed sheet 13 .

[0029] The sheets 12 and 13 are transferred from one printing unit to the other (arrow F), ie in the longitudinal direction from the infeed station 3 to the delivery station 11 . The sheets 12 and 13 are conveyed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com