Stretchable motion device with rope automatic tensioning function

A telescopic movement and automatic technology, applied in the field of rehabilitation robots, can solve problems such as transmission failure, achieve the effect of ensuring automatic tension, realizing automatic compensation, and solving transmission failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following examples are presented to illustrate certain embodiments of the invention and should not be construed as limiting the scope of the invention. The content disclosed in the present invention can be improved simultaneously from materials, methods and reaction conditions, and all these improvements should fall within the spirit and scope of the present invention.

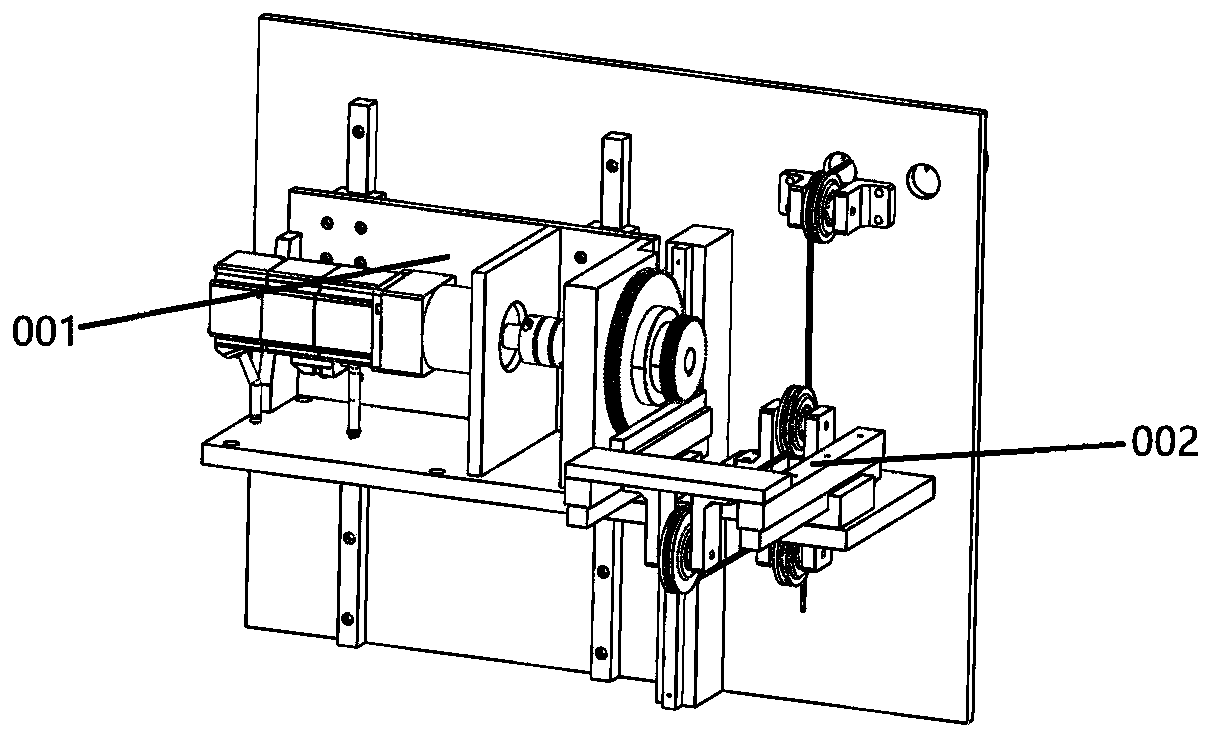

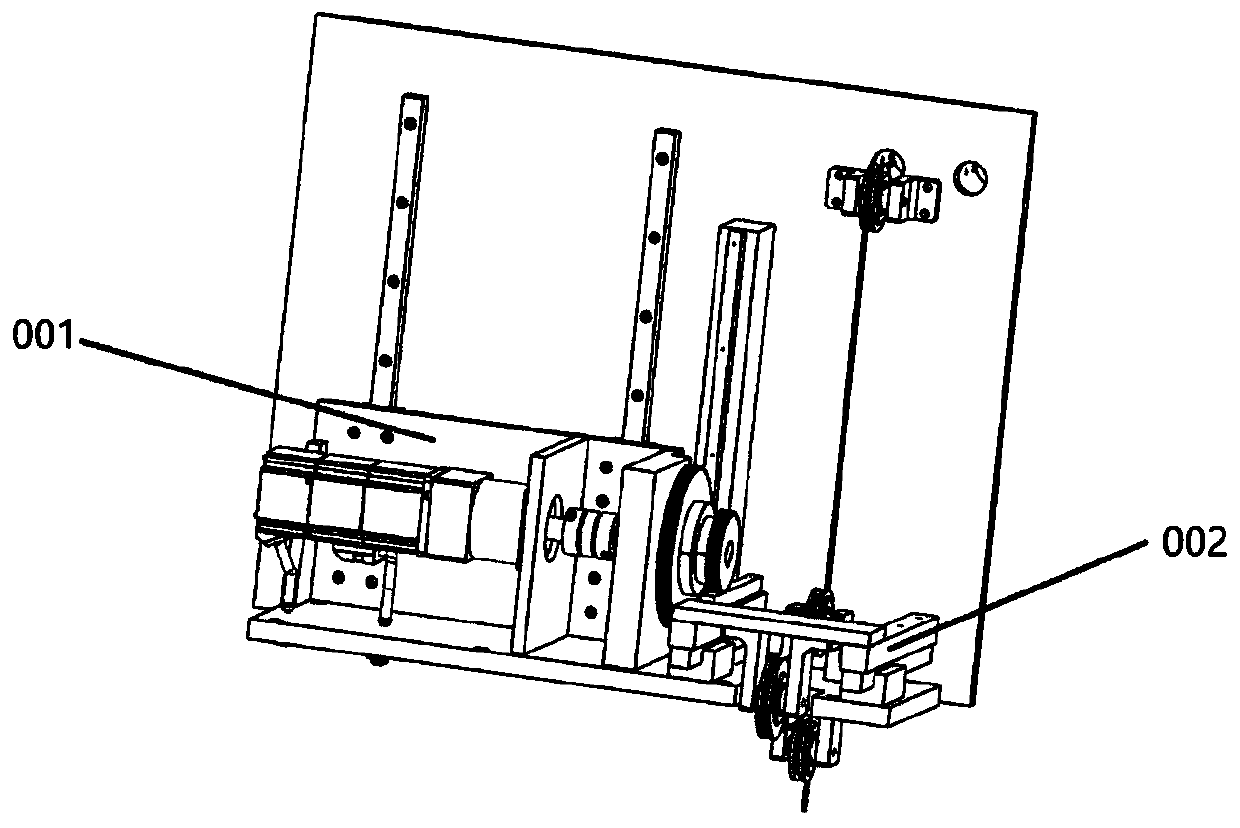

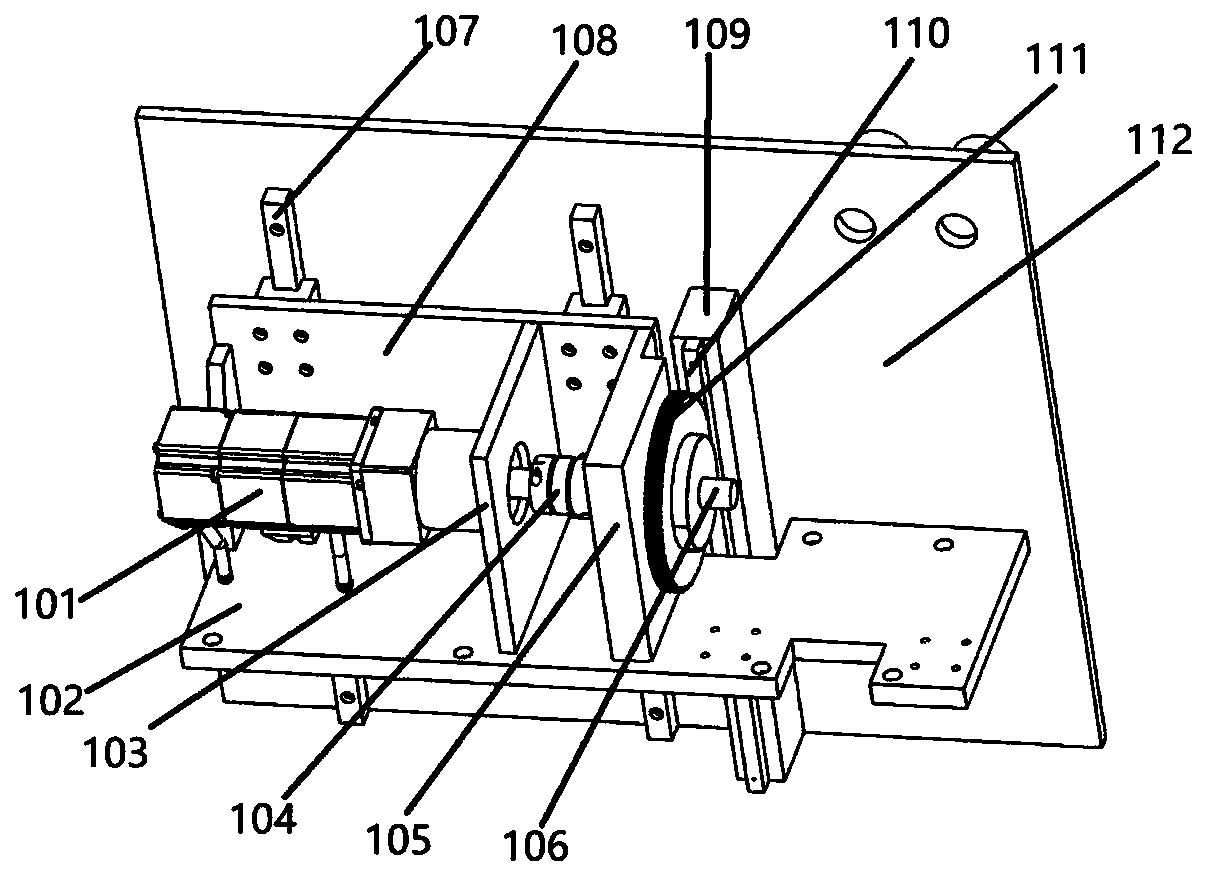

[0027] Such as Figure 1-4 As shown, a telescopic movement device with automatic rope tensioning function of the present application includes a telescopic movement mechanism 001 and a wire rope length compensation mechanism 002, and the telescopic movement mechanism 001 includes a base plate 102 and a motor mounted on the base plate 102 - The output end of the motor-reducer 101 of the reducer 10 is equipped with a rack and pinion mechanism one, and the output end of the rack and pinion mechanism one is fixed on the lifting plate 112; the wire rope length compensation mechanism 002 includes a motor- ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com