Control method for preparation of high-density carbon dioxide

A carbon dioxide and control method technology, applied in chemical instruments and methods, electrical program control, program control in sequence/logic controllers, etc., can solve the problems of high cost and low efficiency, achieve small shock and vibration, and improve work efficiency , The effect of reducing the cost of equipment input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

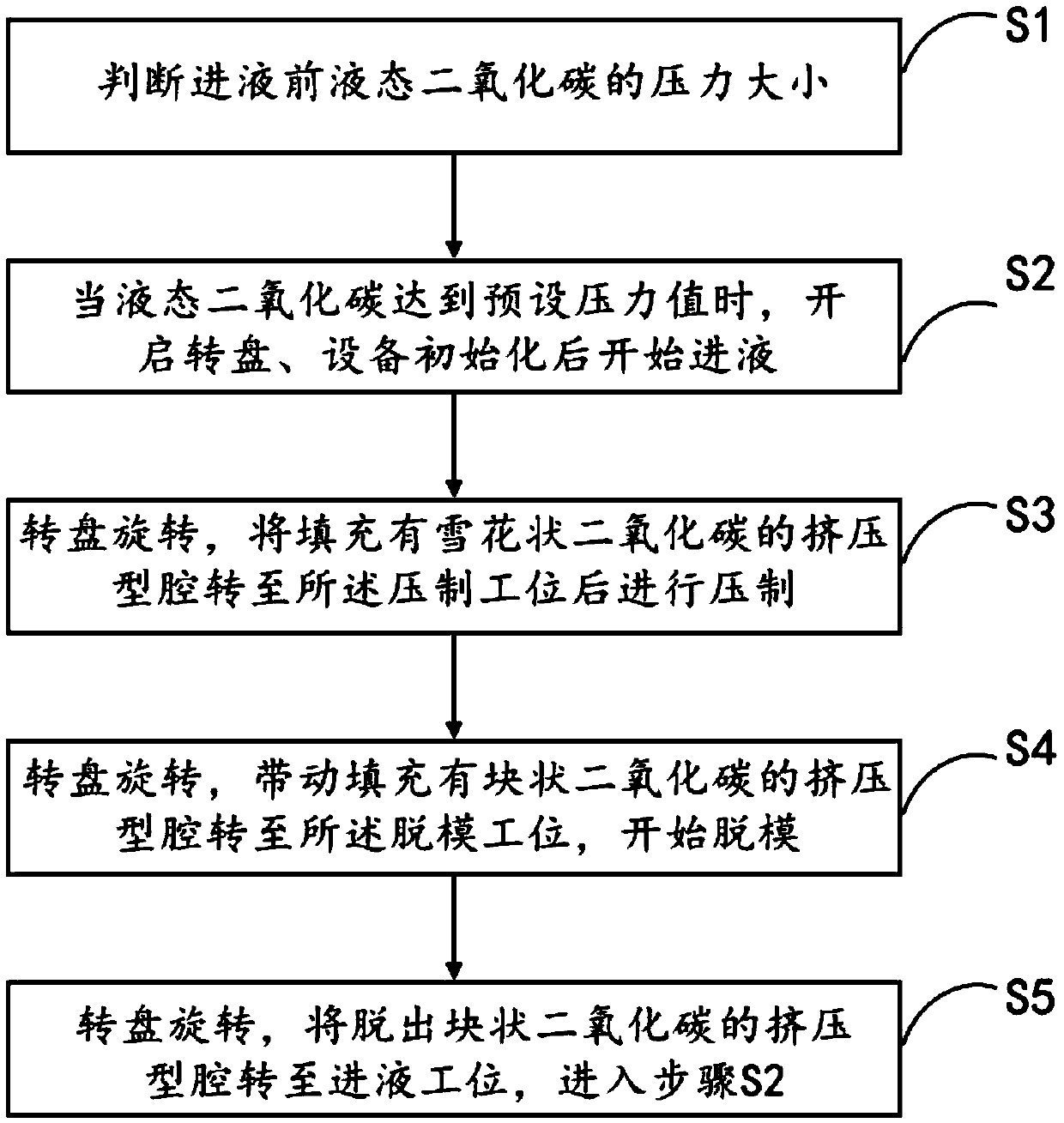

[0055] refer to figure 1 As shown, the present invention provides a kind of control method for preparing high-density carbon dioxide, it is characterized in that, comprises the steps:

[0056] S1. Step 1. After the device is started, it is initialized to check whether the device is running normally. Judging the pressure of the liquid carbon dioxide before entering the liquid, when the liquid carbon dioxide reaches the preset pressure value, enter step 2.

[0057] Optionally, in step 1, the preset pressure value is 1.5-2.2Mpa. Generally speaking, dry ice preparation needs to be carried out under high pressure (8.0MPa), gas CO 2 It is liquefied at room temperature, then expanded into a low-temperature liquid by throttling, and then enters the dry ice machine to prepare dry ice. The power consumption of the equipment is extremely high. The embodiment of the present invention is prepared by using a low-pressure method (1.5MPa-2.5MPa) to prepare dry ice. Liquid CO at low pressu...

Embodiment 2

[0084] refer to figure 1 As shown, this embodiment provides a control method for preparing high-density carbon dioxide, using the following high-density carbon dioxide molding equipment:

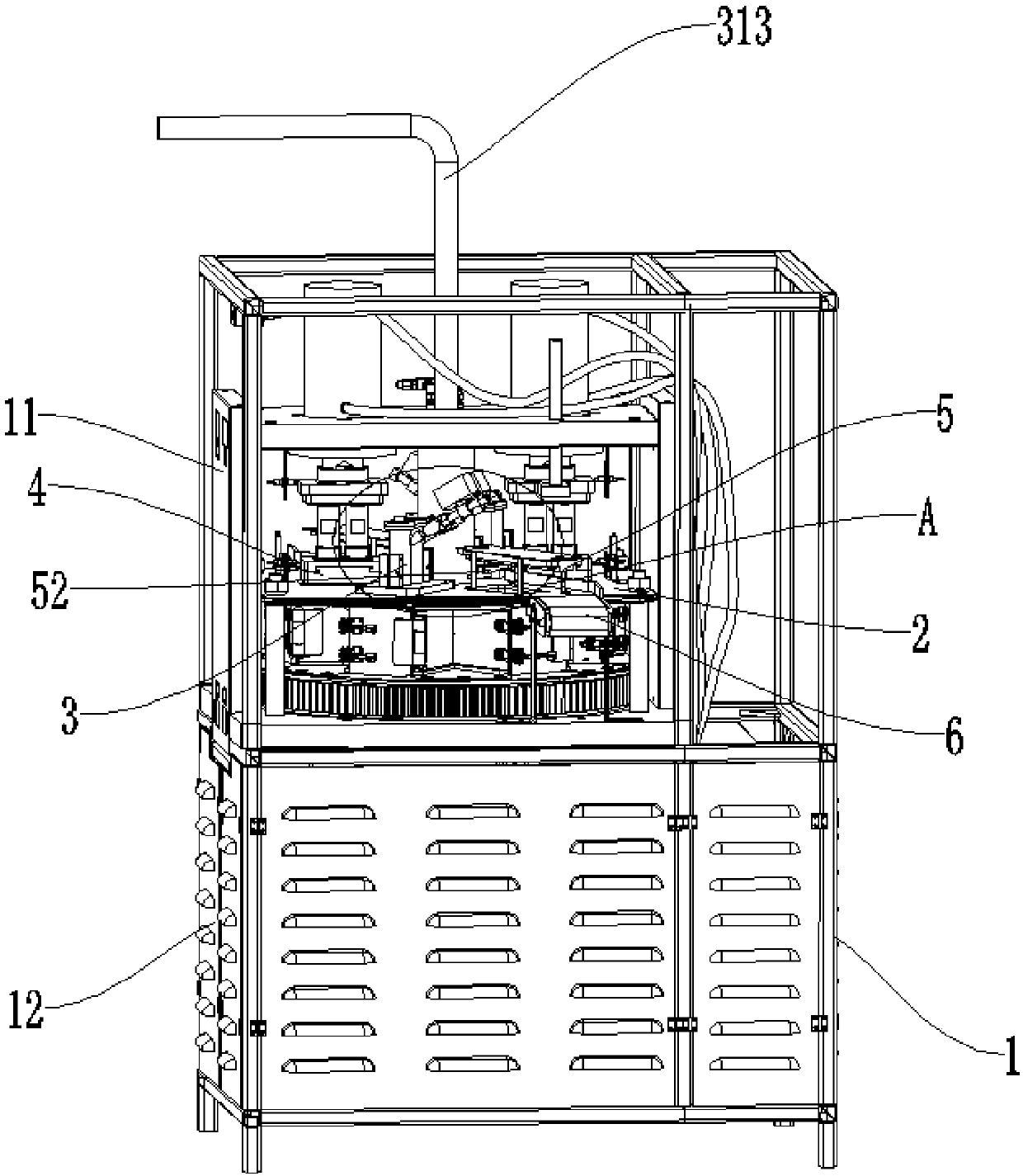

[0085] refer to figure 2 As shown, this embodiment provides a high-density carbon dioxide molding equipment, including a frame body 1 and a turntable 2 , a liquid inlet unit 3 , a pressing unit 4 and a demoulding unit 5 arranged in the frame body 1 . Each unit is independent and cooperates with each other to complete the preparation of high-density solid carbon dioxide.

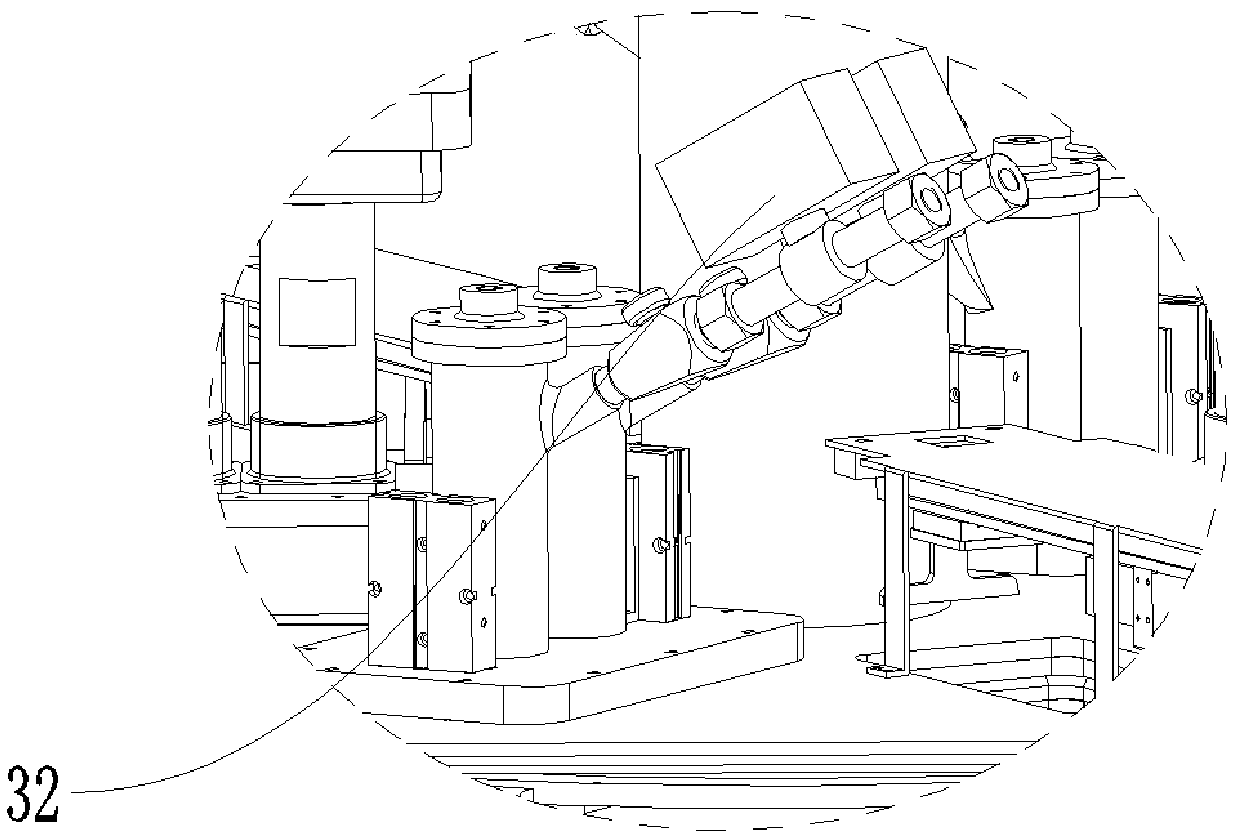

[0086] optional, see figure 2 , 4 As shown, there are at least two liquid inlet stations 22 , pressing stations 23 and demoulding stations 24 , and the same two stations are symmetrically arranged on the turntable 2 . The invention arranges the liquid inlet unit 3, the pressing unit 4 and the demoulding unit 5 along the circumferential direction through the design of the multi-station of the rotary table, so that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com