Non-return valve with valve housing

A technology of one-way valve and valve sleeve, which is applied in the field of hydraulic control valves, can solve the problems affecting the service life of the cone valve, small guide, poor motion stability, etc., and achieve the effect of enhanced life, less leakage and good sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

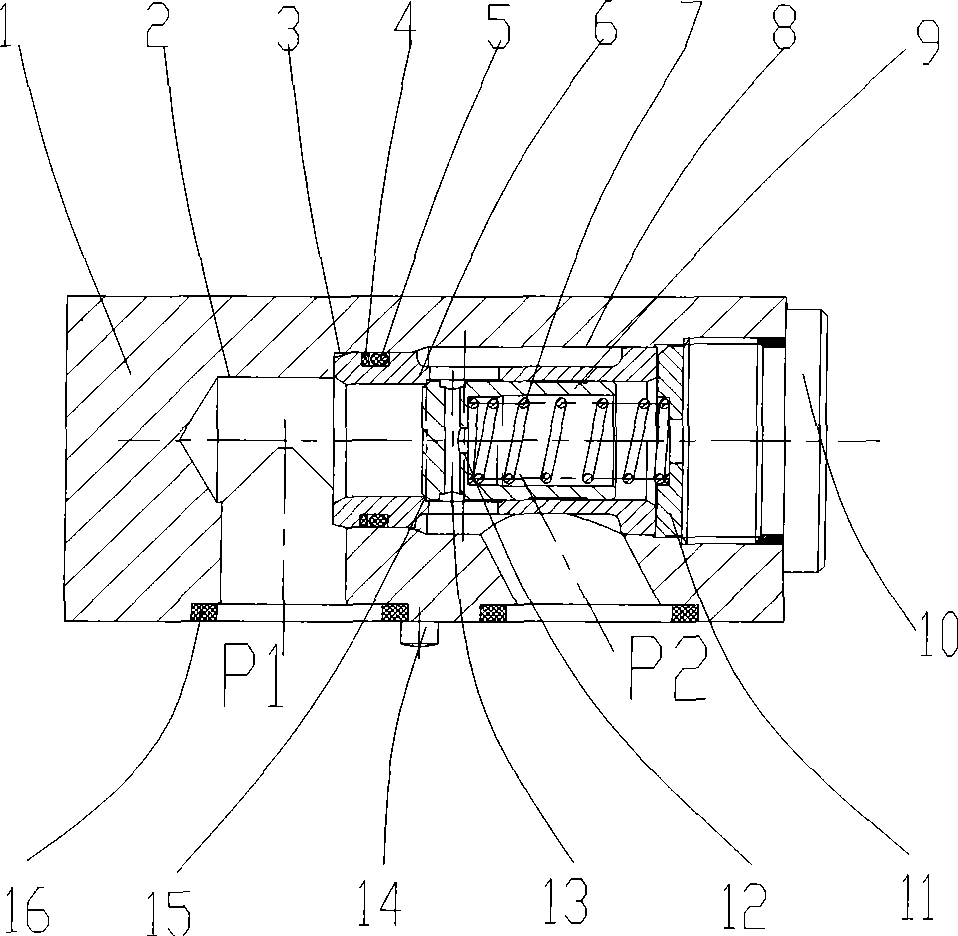

[0027] Such as figure 1 As shown in the illustration, when the hydraulic oil flows in from the P1 port and flows out from the P2 port, the plate check valve shown in the figure is in the closed state, the oil drain port 13 communicates with the oil outlet P2, and the hydraulic oil enters from the P1 cavity. When the opening pressure of the spring 7 is higher than that of the spring 7, the valve core 9 overcomes the opening pressure of the spring 7 and moves to the right, so that the P1 and P2 cavities communicate. The right end face of the core 9 is in contact with the left end face of the spring seat 11, the area of the oil passage is the largest, the spool 9 stops moving, and the two chambers communicate completely. When the pressure of the oil inlet chamber is lower than the opening pressure of the spring 7, the spool 9 immediately moves to the left until the oil sealing port 15 of the spool 9 contacts the oil sealing port of the valve sleeve 6 and the spool 9 closes, rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com