O2 purifying system, and gas treatment system

A raw material gas and sub-channel technology, applied in gas treatment, specific gas purification/separation, oxygen preparation, etc., can solve problems such as prolonging production time consumption, unfavorable device prying, and increased failure probability of valve components, etc., to achieve Reduce the cycle time of pressure swing adsorption, reduce equipment input cost, and reduce the effect of equipment cost investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

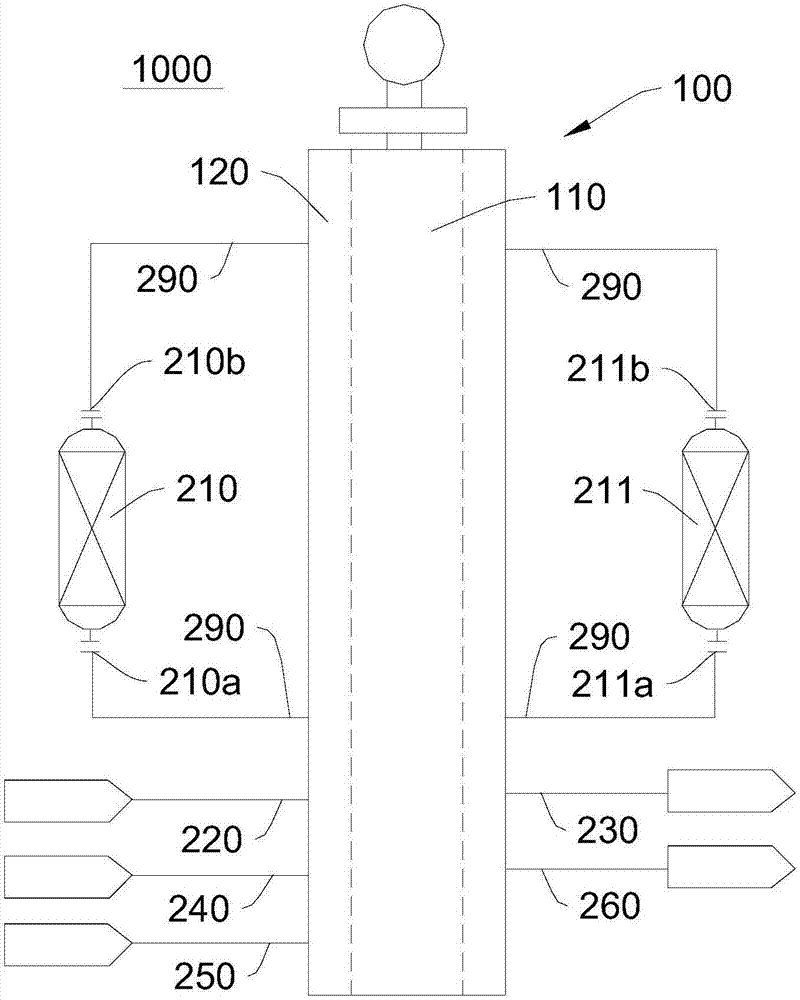

[0040] Please refer to figure 1 , this embodiment provides an O 2 Purification system 1000, O 2 The purification system 1000 includes a rotary valve 100 , an adsorption tower unit (not shown in the figure), a feed gas pipeline 220 , a product gas pipeline 230 , a flushing gas inlet pipe 240 , a final charging pipeline 250 and an evacuation pipeline 260 .

[0041] The feed gas pipeline 220 , the product gas pipeline 230 , the flushing gas inlet pipe 240 , the final charging pipeline 250 , the evacuation pipeline 260 and the adsorption tower unit are all connected to the rotary valve 100 . It should be noted, figure 1 Only the connection relationship between the above-mentioned various pipelines and the various interfaces of the adsorption tower unit and the rotary valve 100 is shown, figure 1 It is a schematic diagram of the connection relationship, and does not limit the location of the connection.

[0042] The rotary valve 100 can selectively connect the feed gas pipeline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com