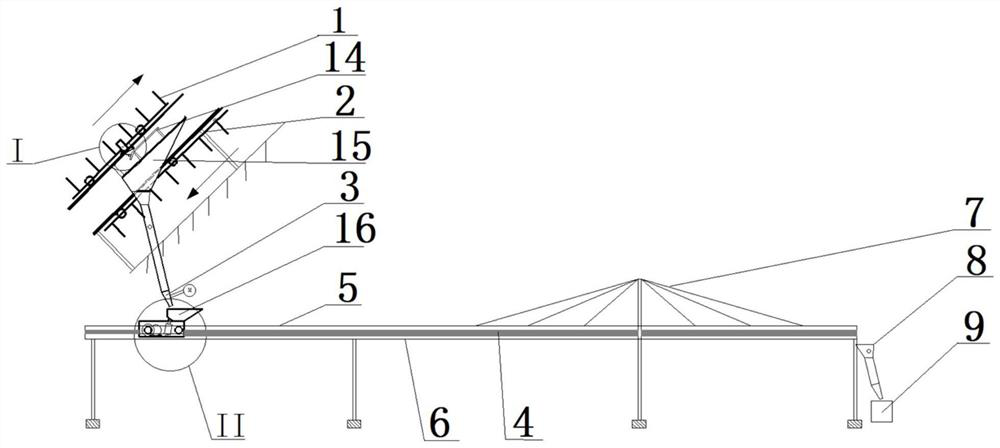

Intelligent sampling and conveying device

A conveying device and intelligent conveying technology, which is applied in the direction of sampling device, sampling, measuring device, etc., can solve the problems of unfavorable industrial application promotion, expensive air conveying system equipment, and narrow use range, so as to reduce labor input cost and reduce equipment cost. The effect of low input cost and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

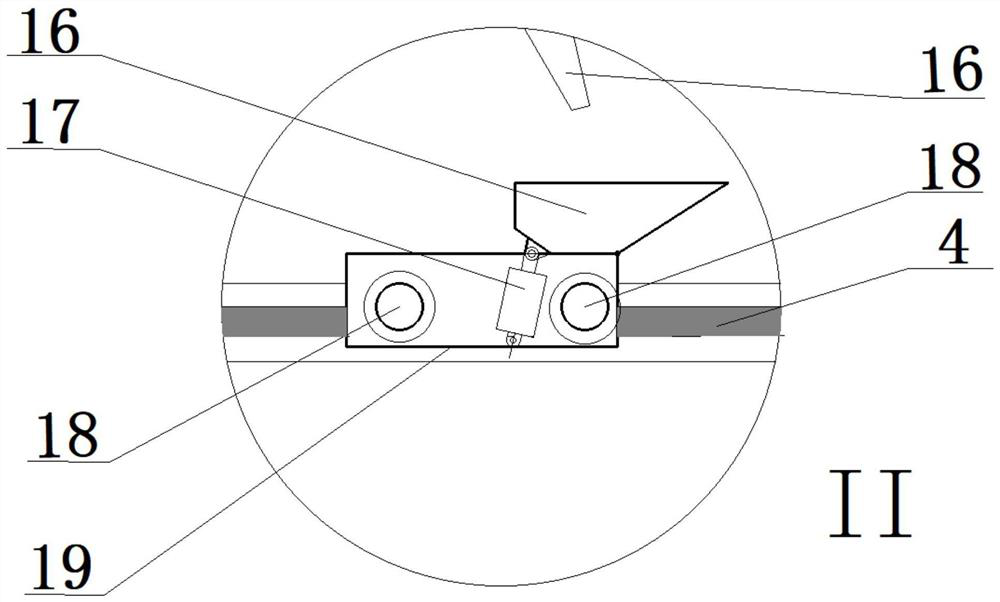

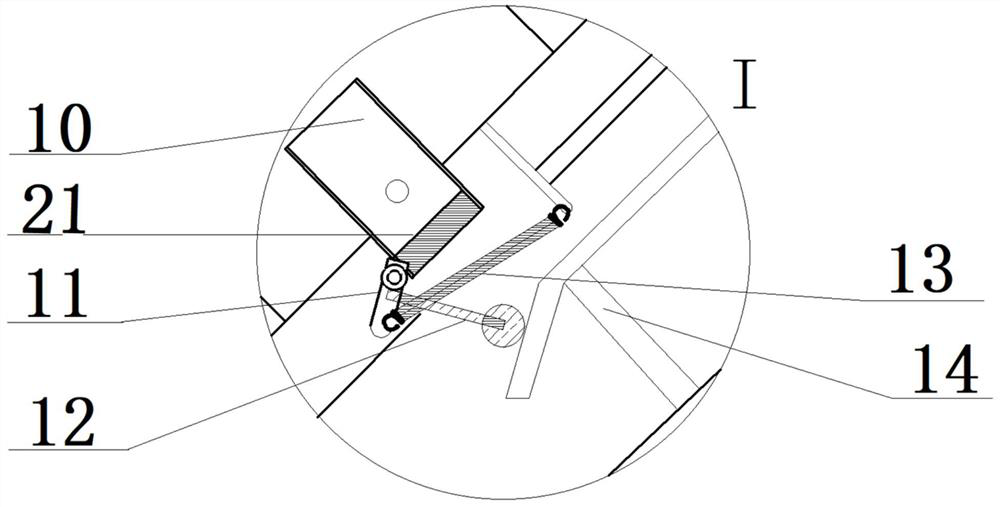

[0039]Firstly, the flapper valve 3 is set to open once every hour through the PLC control device, and the mobile trolley 19 is set to go back and forth every hour at the same time, and it is synchronized with the rotation frequency of the sampling box 10 . When the sampling box 10 rotates to the top of the discharge chute 15 along with the upper hopper 1 of the clinker trough conveyor, the rollers at the bottom of the strut 12 touch the protruding plate of the bracket 14 and are resisted. Generate backward thrust, and drive the crank arm 11 to retreat, the crank arm 11 drives the door 21 to open downwards simultaneously, the spring connecting rod 14 is in a stretched state, at this moment, the material sample in the sampling box enters the blanking retainer 15 and temporarily storage; while the sampling box 10 continues to rotate and advance with the upper hopper 1 of the clinker trough conveyor, the bottom roller of the strut 12 moves to the top of the support along the protru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com