Novel regeneration method for VOC (volatile organic compound) adsorbent

A technology of volatile organic and organic adsorbents, applied in separation methods, filter regeneration, chemical instruments and methods, etc., can solve the problems of high light-off temperature of transition metal catalysts, low light-off temperature of precious metals, and easy scrapping of activated carbon adsorbents, etc. problems, to achieve the effect of being conducive to circular economy and solid waste management and disposal, reducing equipment investment costs, and realizing green and safe discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the invention are described in detail as follows:

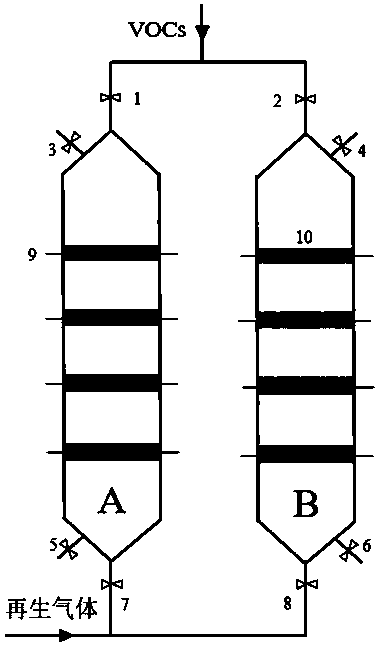

[0020] see figure 1 , In this example, a parallel double-column tower reactor (A and B) is used as the adsorbent regeneration device, and activated carbon adsorbent is layered in the tower. Taking a kind of industrial flue gas as regeneration gas as an example, the amount of regeneration gas is 3000-7000 m 3 / h; the regeneration gas passes through the dedusting device; the temperature after dedusting is 280-300°C, and the regeneration gas contains 5000 ppm NOx, 5000 ppm CO and 5000 ppm SOx, etc. The method steps of VOCs adsorbent regeneration are as follows:

[0021] a. Open valve 1, feed VOCs into tower A that has been loaded with adsorbent, and open valve 5 to discharge the gas. After tower A reaches adsorption saturation, close valves 1 and 5, then open valve 7 to feed regeneration gas into tower A, and turn on the heater to keep the temperature of the adsorbent between 200-300°C, and open valve 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com