Soldering method of seat plate assembly, induction coil for soldering and manufacturing method of induction coil

A welding method and induction coil technology, applied in coil manufacturing, coil, welding equipment and other directions, can solve the problems of high welding cost and human body injury, and achieve the effect of low welding cost, low equipment investment cost and good operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

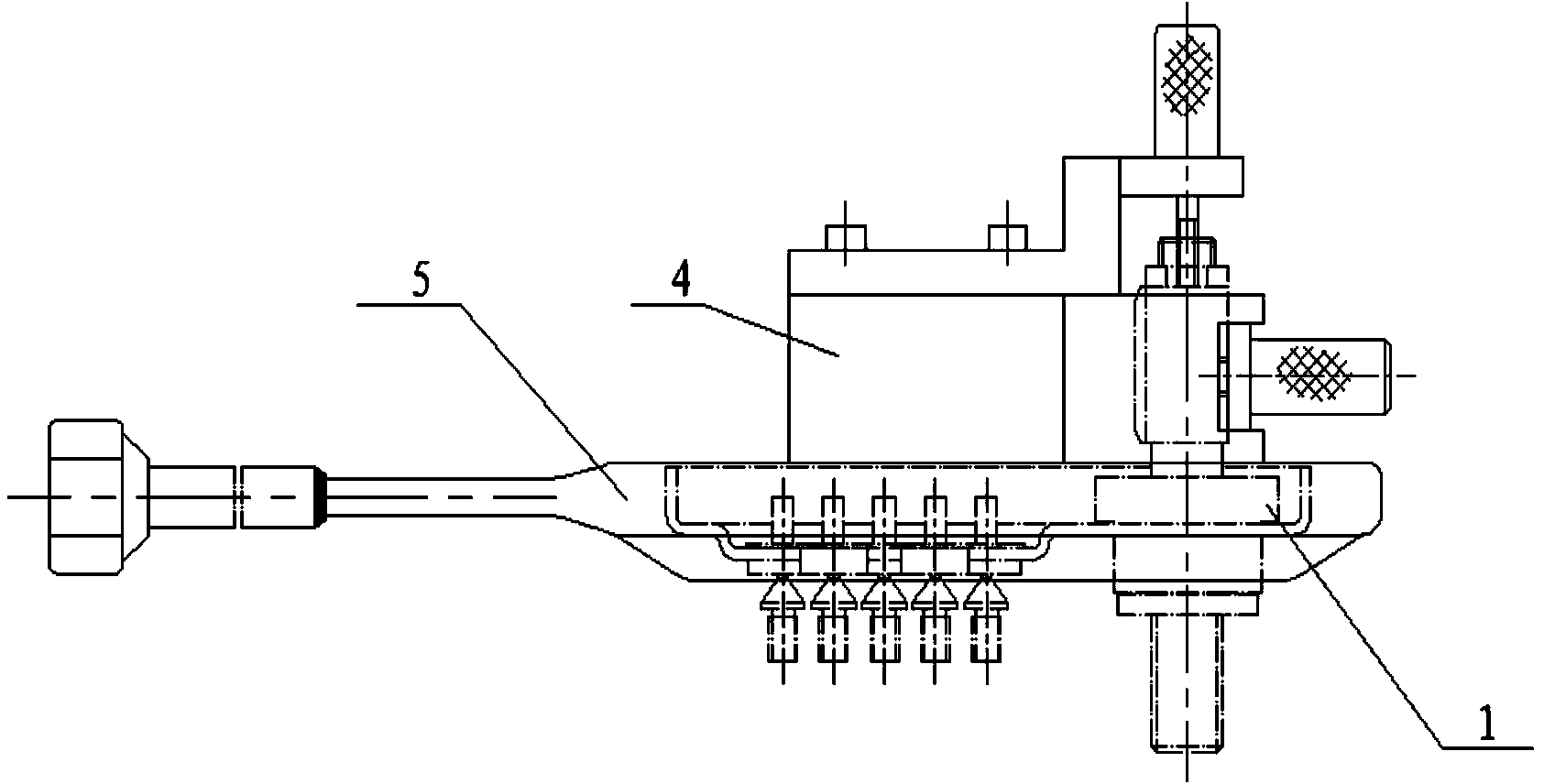

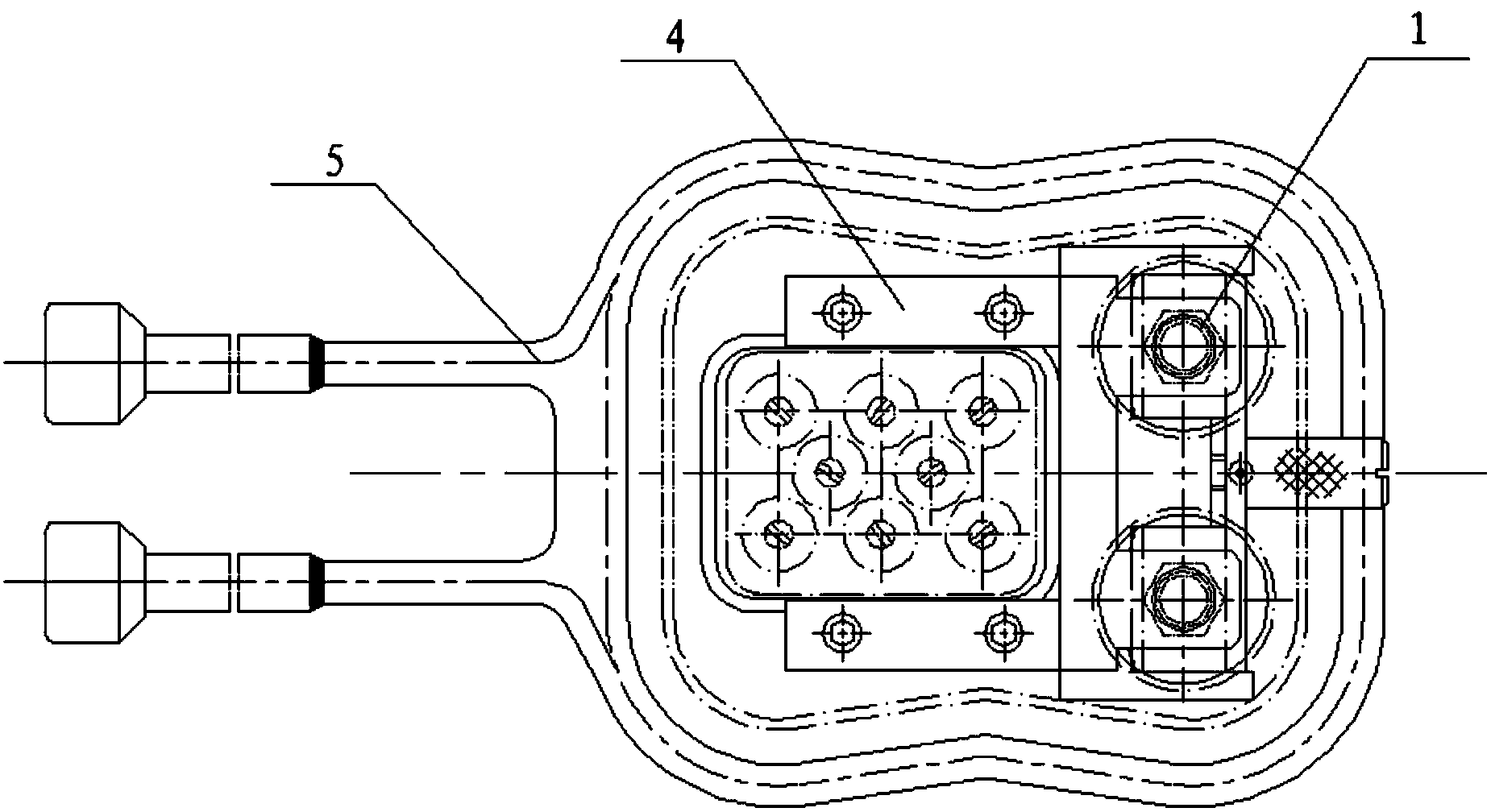

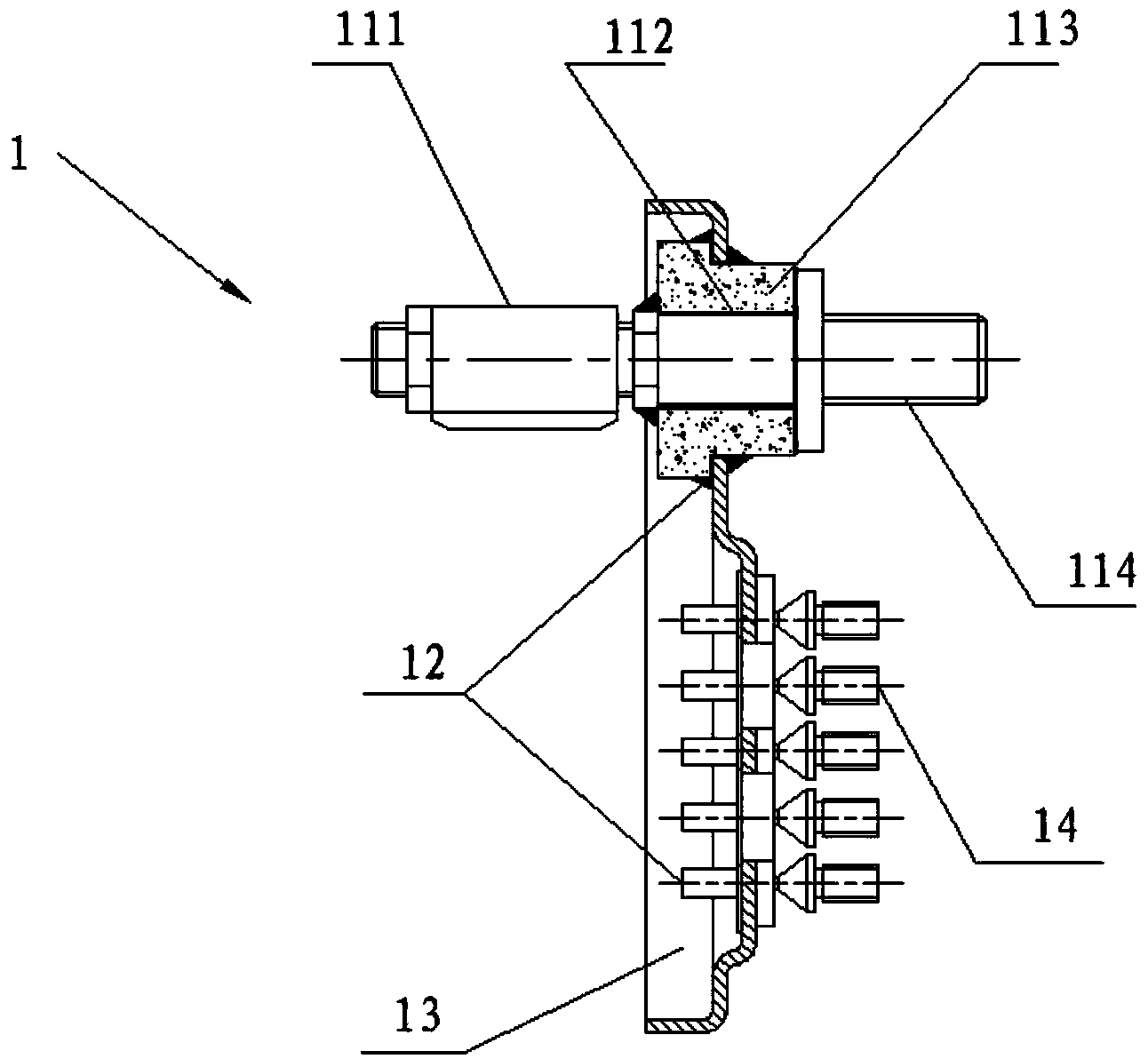

[0047] refer to figure 1 , figure 2 As shown, the present invention provides a welding method for a seat plate assembly, which includes passing an induction coil with a high-frequency current to be sleeved on the seat plate assembly 1 with filled solder, and using the heat generated by the induction coil to melt the filled solder pair The seat plate assembly 1 is sealed and welded. In this embodiment, the induction coil with a high-frequency current makes full use of the two major effects (skin effect and proximity effect) in high-frequency heating to stimulate the thermal effect of the welded parts when they are induced, and improve the temperature of the solder during the welding process. Excellent permeability, avoid welding voids and discharge welding excess to the greatest extent, improve the mechanical strength and sealing performance of the we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com