Flexible job-shop scheduling multi-objective method

A technology for workshop scheduling and flexible operations, applied in control/regulation systems, instruments, comprehensive factory control, etc., can solve the problems of limited influence of experimental results, lack of theoretical basis for simulation methods, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

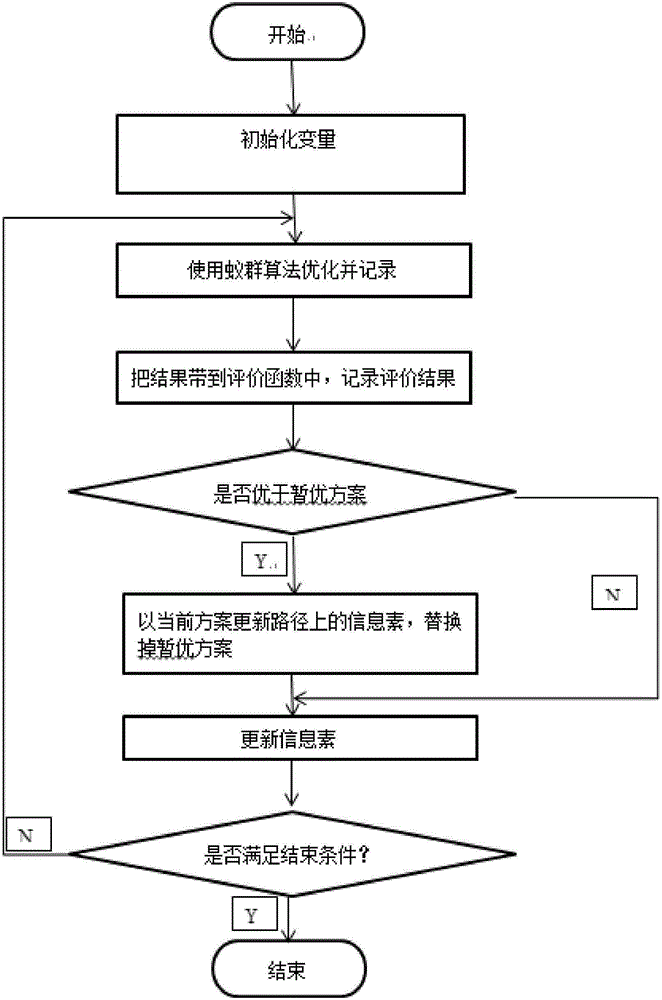

Method used

Image

Examples

Embodiment

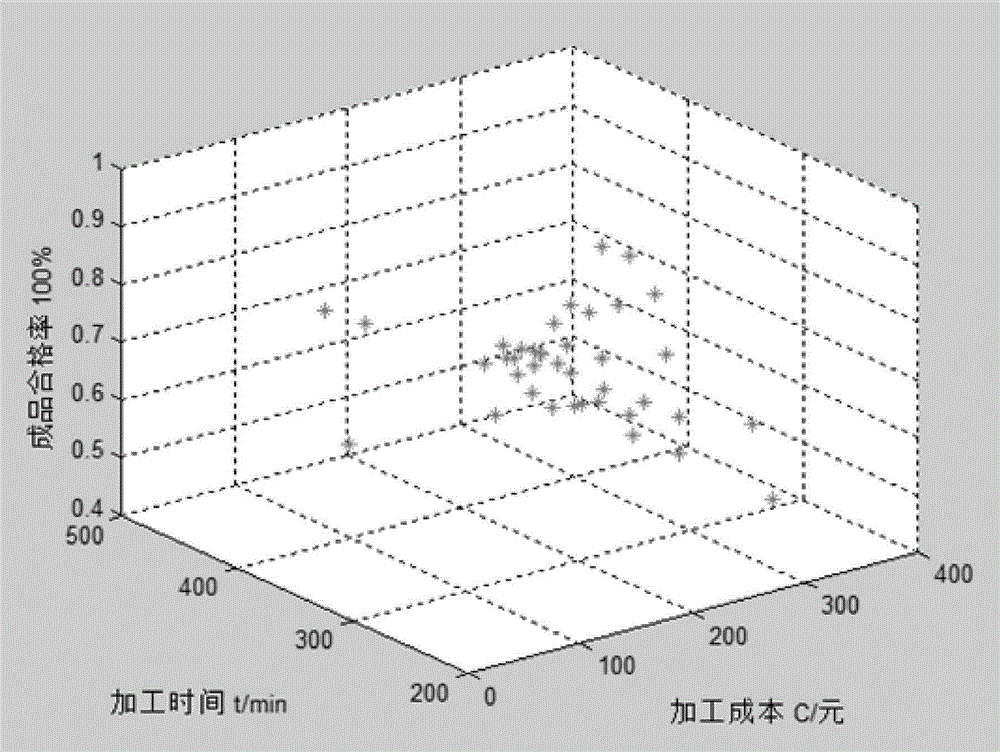

[0071] Taking the lifting equipment painting workshop of a heavy machinery group as an example, the multi-objective optimization of flexible workshop scheduling is carried out. The workshop has the main equipment required for coating processing, including pre-treatment devices, cathodic electrophoresis equipment, dryers, grinders, gluing manipulators and online testing equipment. T obtained through the record data and order item table of the operation process and status on a production line in the workshop ijk , C ijk and h i and other parameters, after calculation and processing, the problem of flexible workshop scheduling with 6 workpieces and 10 equipment, and each workpiece has several processes is obtained. The specific workpiece machine information is shown in Table 1, where 1 means occupied and 0 means not used. The index values of processing cost and processing time of different equipment for different processes are shown in Table 2.

[0072] The following table ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com