Plunger piston shoe structure used for swash plate type axial plunger pump or motor

A technology of axial plunger pump and swash plate type, which is applied in the field of plunger pump parts, can solve the problems of affecting the working efficiency and operation of the plunger pump, increasing the use cost of the plunger pump, high manufacturing cost, etc., reaching the limit of heat treatment less, lower maintenance costs, and easy procurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

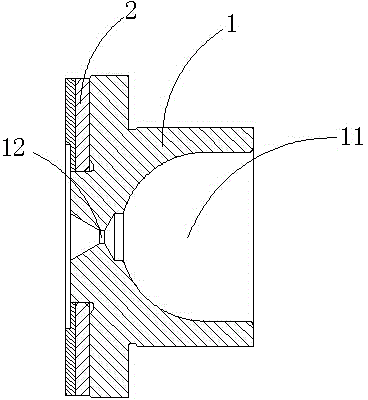

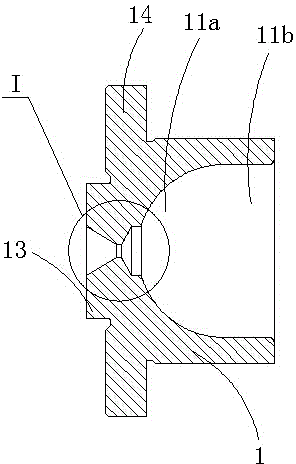

[0027] like Figure 1 to Figure 5 Shown is a schematic diagram of the structure of the present invention,

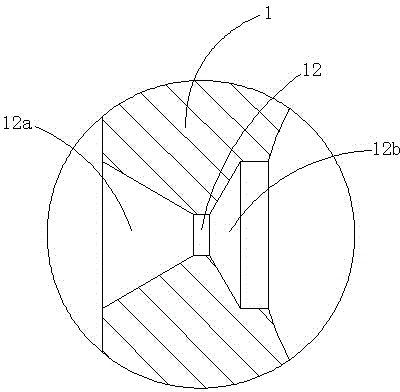

[0028] The reference signs are: sliding shoe body 1, ball-accommodating cavity 11, ball-accommodating portion 11a, extension portion 11b, oil filling hole 12, first buffer portion 12a, second buffer portion 12b, annular protrusion 13, annular edge 14 , Liner 2, copper base 21, annular groove 21a, steel base 22, through holes 23, chamfer 23a.

[0029] like Figure 1 to Figure 5 shown,

[0030] A plunger sliding shoe structure for a swash plate type axial plunger pump or motor of the present invention includes a sliding shoe body 1, and the sliding shoe body 1 is provided with a ball-accommodating cavity adapted to the head of the plunger 11. An oil filling hole 12 is provided on the main body 1 of the sliding shoe, and the oil fillin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com