Processing technique of mobile phone shell, mobile phone shell, and mobile phone

A mobile phone shell and processing technology, which is applied to the structure of telephone sets, telephone communications, electrical components, etc., can solve the problems of complex internal structure of mobile phone shells, inability to reduce the total cost of mobile phones, and unsuitability for large-scale batch processing. It is suitable for mass production, elegant appearance and shortened production cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

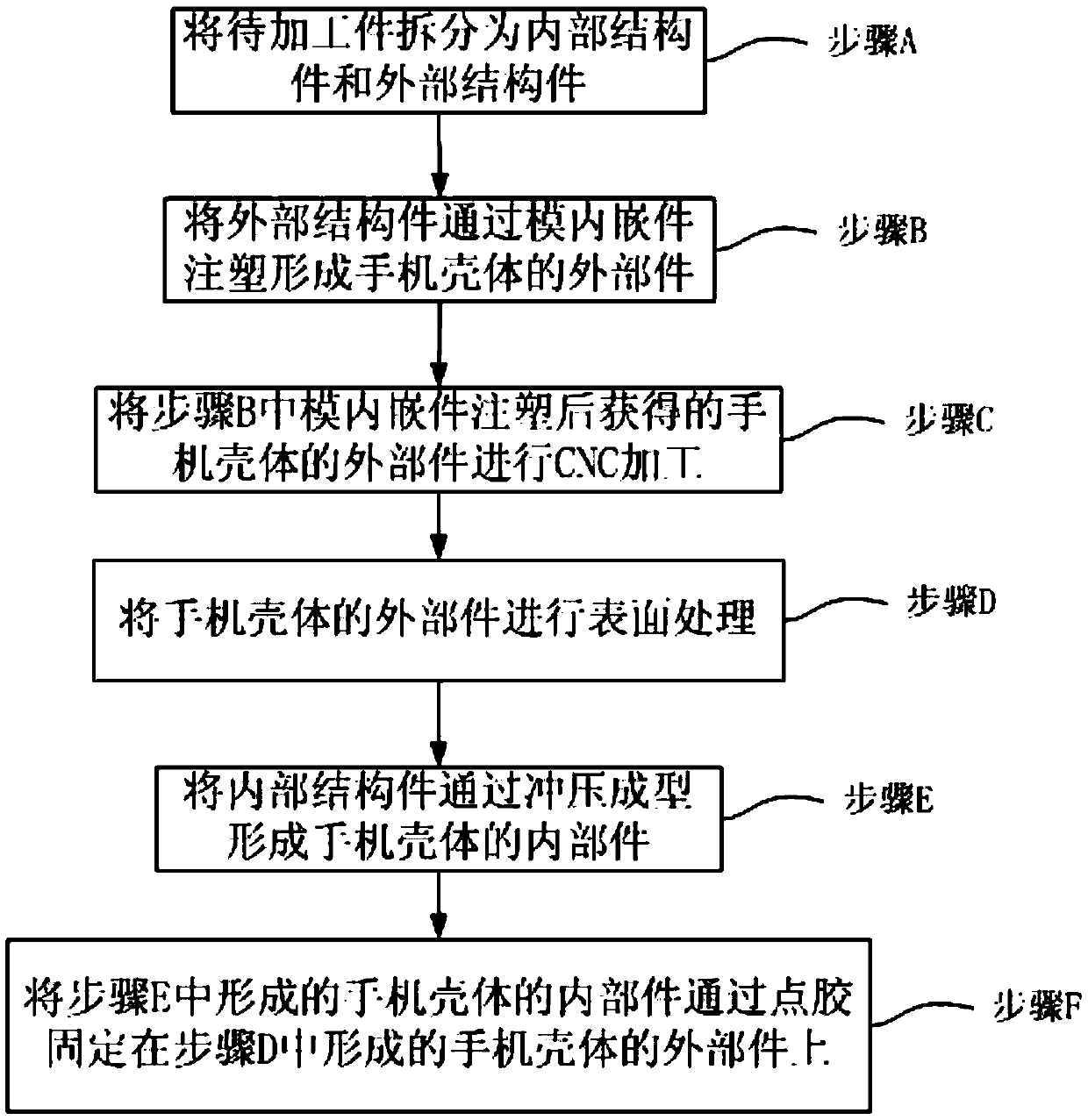

[0033] The preferred embodiment discloses a mobile phone casing processing technology. Such as figure 1 As shown, the mobile phone shell processing technology specifically includes the following steps:

[0034] Step A, splitting the workpiece to be processed into internal structural parts and external structural parts, wherein, the workpiece to be processed is preferably hardware, and can also be made of other materials, as long as it can meet the processing and use requirements. In this step, the The workpiece to be processed is divided into two parts for processing separately, without affecting the processing efficiency and yield rate, the processing is very convenient, and the yield rate is high;

[0035] Step B. Form the outer parts of the mobile phone casing by filling the external structural parts with the plastic structure through injection molding of the in-mold inserts, avoiding the long processing cycle, low yield and low production efficiency of the existing mobile...

Embodiment 2

[0042] The preferred embodiment discloses a mobile phone casing processing technology. The mobile phone casing processing technology is basically the same as that of the preferred embodiment 1, specifically comprising the following steps:

[0043] Step A, splitting the hardware to be processed into internal structural parts and external structural parts;

[0044] Step B, forming the outer parts of the mobile phone casing by injecting and filling the outer structural parts with the plastic structure through the in-mold insert;

[0045] Step C, CNC machining the outer parts of the outer parts of the mobile phone casing obtained after the injection molding of the mold insert in step B;

[0046] Step D, performing surface treatment on the outer part of the mobile phone casing obtained after CNC machining the outer side material in step C;

[0047] Step E, forming the inner parts of the mobile phone casing by die-casting the inner structural parts;

[0048] Step F, fixing the in...

Embodiment 3

[0050] The preferred embodiment discloses a mobile phone casing processing technology. The mobile phone casing processing technology is basically the same as that of the preferred embodiment 1, specifically comprising the following steps:

[0051] Step A, splitting the hardware to be processed into internal structural parts and external structural parts, and the yield rate is high;

[0052] Step B, carrying out T treatment (i.e. tempering treatment) on the external structural parts, this step can also be omitted if the rubberized structure is good enough;

[0053]Step C, forming the outer parts of the mobile phone casing by injecting the external structural parts through the in-mold inserts to fill the plastic structure, avoiding the long processing cycle, low yield and low production efficiency of the existing mobile phone casings with CNC (numerical control machine tools) and other issues, greatly reducing production costs;

[0054] Step D, CNC machining the outer parts of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com