Heat treatment method for shear blade

A heat treatment method and workpiece technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve problems such as easy cracks, achieve the effects of reducing internal stress, improving hardness and wear resistance, and avoiding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Flying shears for cold rolling, the cutting blade size is 40mm×65mm×2030mm, the chemical composition and its mass percentage are: C1.4~1.6%, Si≤0.6%, Mn≤0.6%, Cr11.0~13.0% , Mo0.7~1.2%, V0.5~1.1%.

[0032] The production process includes the following steps:

[0033] A. Prepare forging blanks according to the above-mentioned chemical components and their mass percentages;

[0034] B. Carry out isothermal spheroidization treatment on the forged billet, firstly heat to 850°C, hold for 6 hours, then cool down to 790°C, hold for 6 hours, process the forged billet to the size close to the finished product, and control the margin at 2-3mm to obtain the workpiece;

[0035] C. Heat the workpiece to 1000°C and keep it warm for 4 hours;

[0036] D. Use a spray quenching machine to spray water + blowing to quench the workpiece. When spraying water + blowing, the water pressure is 2MPa, the wind pressure is 2MPa, and the cooling rate is 50°C / min; when the temperature of the workp...

Embodiment 2

[0039] Flying shears for hot rolling, the size of the cutting blade is 100mm×190mm×1550mm, the chemical composition and its mass percentage are: C0.4~0.7%, Si0.8~1.2%, Mn0.2~0.5%, Cr4. 75-5.50%, Mo1.1-1.75%, V0.8-1.2%.

[0040] The production process includes the following steps:

[0041] A. Prepare forging blanks according to the above-mentioned chemical components and their mass percentages;

[0042] B. Carry out isothermal spheroidization treatment on the forging billet, firstly heat it to 830°C, keep it warm for 7 hours, then lower the temperature to 770°C, keep it warm for 8 hours, process the forged billet to the size close to the finished product, and control the margin at 2-3mm to get the workpiece;

[0043] C. Heat the workpiece to 1050°C and keep it warm for 4 hours;

[0044] D. Use a spray quenching machine to spray water + blowing to quench the workpiece. When spraying water + blowing, the water pressure is 2MPa, the wind pressure is 2MPa, and the cooling rate is...

Embodiment 3

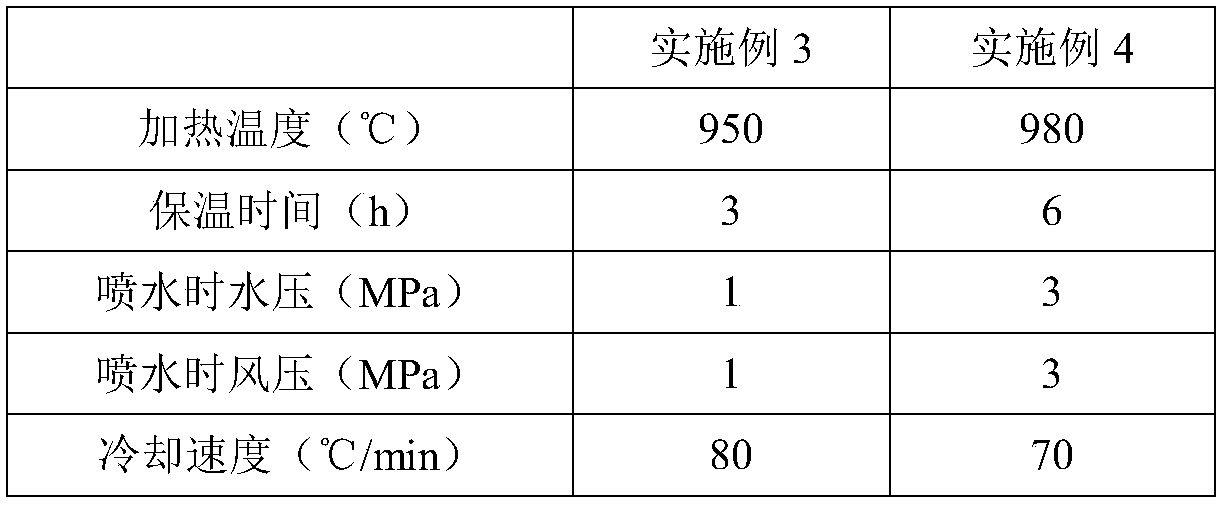

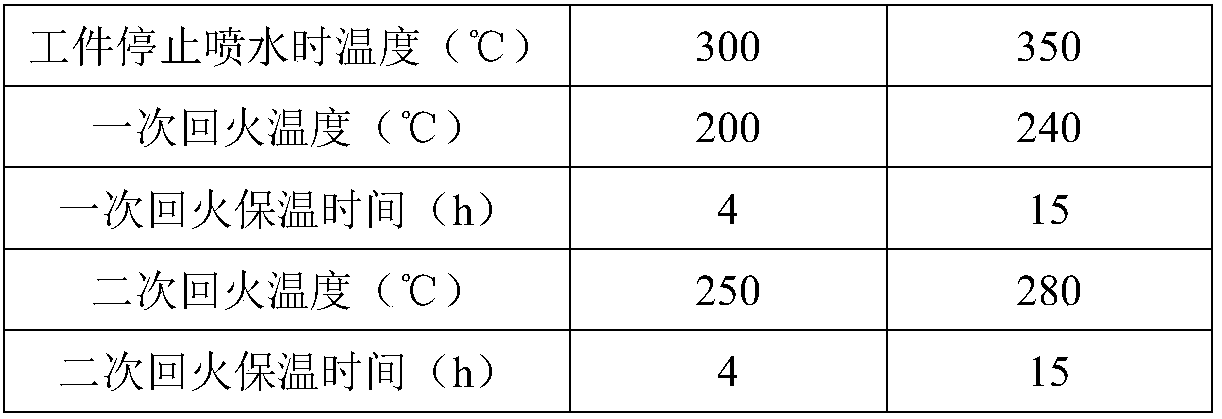

[0047] Embodiments 3 to 4 are the same as the above-mentioned embodiment 1, except that the size of embodiment 3 is 30mm × 55mm × 1500mm, the chemical composition and mass percentage thereof are the same as those of embodiment 1, and the size of embodiment 4 is 120mm × 1500mm. 180mm×2350mm, the chemical composition and mass percentage are the same as those in Example 2, and the different process parameters are shown in Table 1 below.

[0048] Table 1

[0049]

[0050]

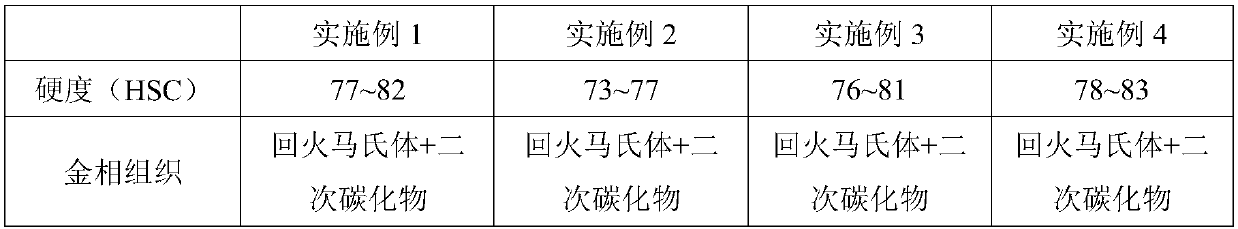

[0051] After testing, the hardness and metallographic structure of the shear blades finally prepared in Examples 1-4 are shown in Table 2.

[0052] Table 2

[0053]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com