Preparation method of alumina polycrystalline material block

A kind of technology of alumina and crystal material, applied in the field of preparation of alumina polycrystalline material block

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The process and steps of this embodiment are described as follows:

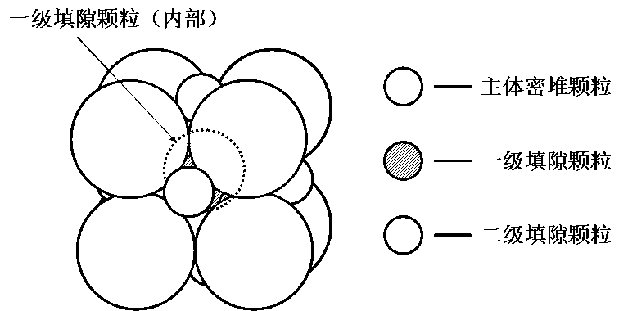

[0025] 1. Commercial high-purity 5N (99.999%) a-Al with two different particle diameters of aluminum alkoxide method 2 O 3 The powder is the raw material, and the ratio of the average particle size is 1:0.15, and the weight ratio is 1:0.1. Specifically, 2400 g for 50 μm large particle size powder, 240 g for 7.5 μm small particle size powder, with a total weight of 2640 g. The theoretical porosity calculated according to the close-packed model is 25.56%.

[0026] 2. Divide the above powder into 4 parts of equal quality, and fill them alternately layer by layer into a self-made rubber bucket mold with a diameter of 150 mm and a height of 130 mm. The rubber mold is always placed on the vibration table during the feeding process, and vibration with a vertical frequency of 500 Hz is applied;

[0027] 3. After the filled rubber mold is sealed, it is placed in an isostatic press and kept under a pressure of 200 MP...

Embodiment 2

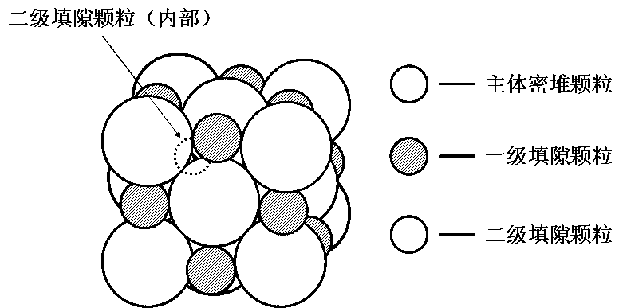

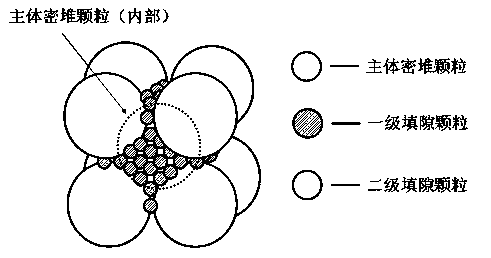

[0030] The purity and a-Al of the powder raw materials used in this example 2 O 3 The method and steps for pressing the polycrystalline block are exactly the same as those in Example 1. The difference lies in the use of three different particle diameters of aluminum alkoxide method a-Al 2 O 3 The powder is the raw material, the average particle size is 10 μm, 7 μm and 3 μm respectively (that is, the ratio of the three particle diameters is 1:0.7:0.3), and the weight is respectively 1800 g, 720 g and 108 g (that is, the weight ratio of the three 1:0.4:0.06), the total weight is 2628g. The theoretical void ratio calculated according to the close-packed model is 24.08%.

[0031] After testing, using the methods and steps described in this example, the final diameter is 114 mm, the height is 70 mm, and the density is 3.69 g / cm 3 A-Al 2 O 3 Polycrystalline bulk. The sample has good moldability, no cracks on the surface, and a relative density of 93%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com