Electrical component

A technology of electrical components and components, applied in the direction of electrical components, circuits, electrical switches, etc., can solve the problems of complex forming mold structure, cutting off and applying of formed products, etc., and achieve the effect of simplifying the mold structure and preventing bad situations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0108] In the first embodiment of the present invention, the electrical component 100 of the present invention will be described using the drawings. It should be noted that, in the first embodiment of the present invention, the electrical component 100 is a switchgear, but the present invention is not limited thereto.

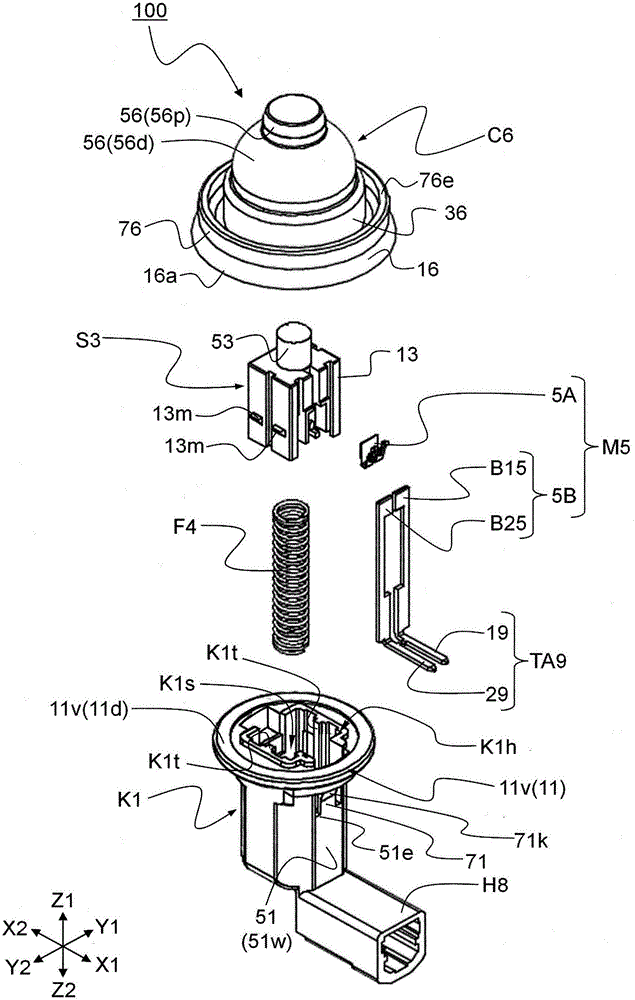

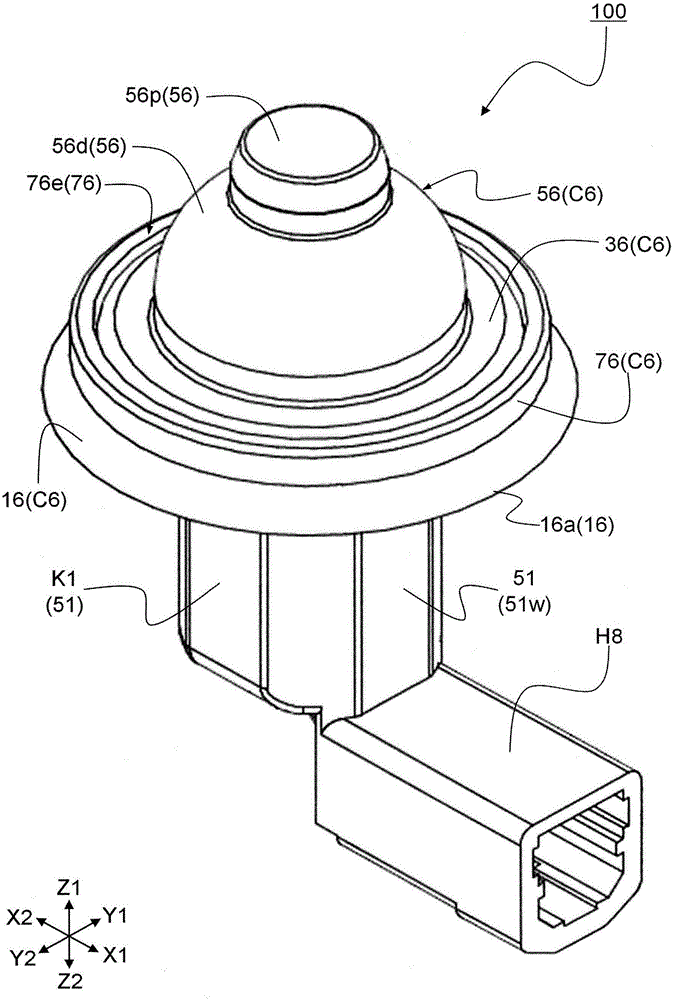

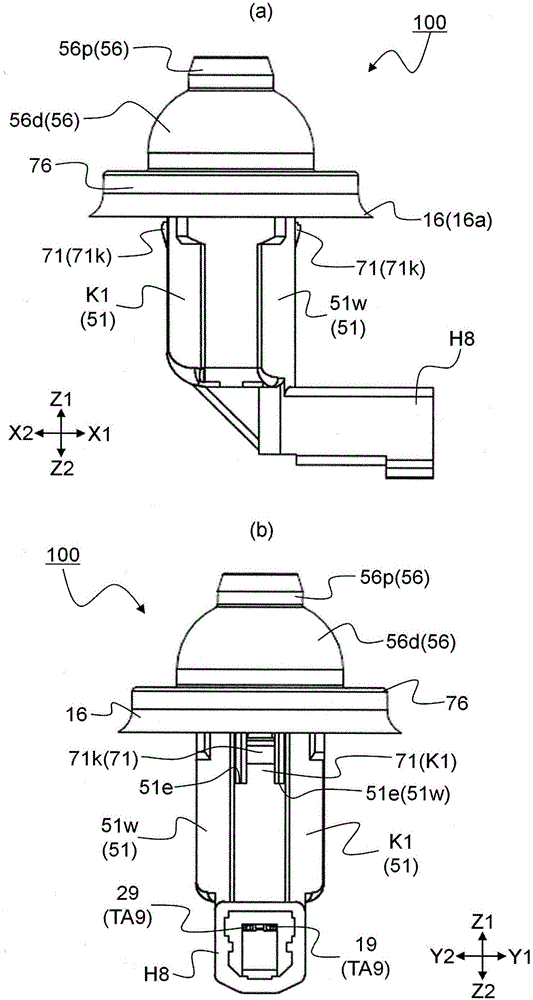

[0109] figure 1 It is an exploded perspective view for explaining the electric component 100 which concerns on 1st Embodiment of this invention. figure 2 is a perspective view of the electrical component 100 . image 3 It is a figure for explaining the electric component 100 of 1st Embodiment of this invention, image 3 (a) is viewed from the Y2 side figure 2 when the main view, image 3 (b) is viewed from X1 side figure 2 time side view. Figure 4 It is a figure for explaining the electric component 100 of 1st Embodiment of this invention, Figure 4 (a) is a perspective view of the mounted portion 500 to which the electrical component 100 is mounted...

no. 2 approach

[0179] Also in the second embodiment of the present invention, the electrical component 200 of the present invention as a switchgear will be described using the drawings.

[0180] Figure 15 It is a perspective view for demonstrating the electrical component 200 which concerns on 2nd Embodiment of this invention. Figure 16 It is a figure for demonstrating the electrical component 200 which concerns on the 2nd Embodiment of this invention, Figure 16 (a) is viewed from the Y2 side Figure 15 when the main view, Figure 16 (b) is viewed from X1 side Figure 15 time side view. Figure 17 It is an exploded perspective view of the electrical component 200 . Figure 18 is along with Figure 6 A longitudinal cross-sectional view of the electrical component 200 cut with the same hatching. Figure 19 is along with Figure 7 A longitudinal cross-sectional view of the electrical component 200 cut with the same hatching. In addition, the electrical component 200 of the second em...

Deformed example 1

[0254] In the above-mentioned first embodiment, a preferred structure is adopted to easily fix the electrical component 100 to the mounted portion 500 using the engaging member 71, but the present invention is not limited thereto, and may be configured such that it is pressed from above the cover member C6, for example. The flange portion 11v of the housing K1 is thus provided with a mounting mechanism restrained from the outside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com