Wheat bran tableware and preparation method thereof

A technology of wheat bran and tableware, which is applied in the field of wheat bran tableware and its preparation, can solve the problems of not easy to rot and degrade, easy to catch fire, and endanger the environment, so as to improve the withstand pressure and tensile breaking performance, and improve the tensile strength. Good performance and sensory indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

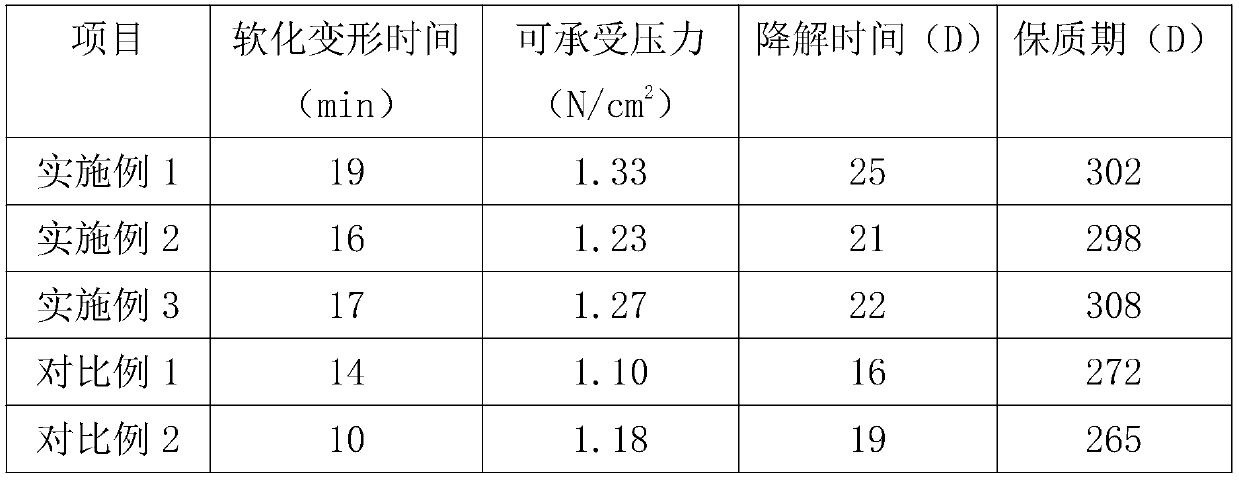

Examples

Embodiment 1

[0028] The method for preparing dietary fiber comprises the following steps:

[0029] (1) Weigh 20 parts of wheat bran, add 200 parts of water, add 36% acetic acid to adjust the pH to 5.0, soak for 30min; then add 0.5% of the total mass of α-amylase at 100°C Water bath for 50min, filter, add the solid in the same volume of acetic acid solution with a mass fraction of 2% sodium hydroxide for alkaline hydrolysis for 30min, then add water to wash to pH 7.0, drain to obtain insoluble dietary fiber;

[0030] (2) baking the insoluble dietary fiber obtained by the treatment in step (1), the baking temperature is 65° C., and the baking makes the water content of the insoluble dietary fiber to 12.0% to form a modified insoluble dietary fiber for use.

[0031] The preparation method of modified xanthan gum comprises the steps:

[0032] (1) get 6 parts of xanthan gum and add 2 times the volume of water, after stirring and dissolving, be warmed up to 60 ℃, then add 5 parts of maltose, 1 ...

Embodiment 2

[0041] The preparation method of dietary fiber comprises the following steps:

[0042] (1) Weigh 20 parts of wheat bran, add 200 parts of water, add 36% acetic acid to adjust the pH to 5.5, soak for 60min; then add 0.6% of the total mass of α-amylase at 100°C Water bath for 50min, filter, add the solid in the same volume of acetic acid solution with a mass fraction of 2% sodium hydroxide for alkaline hydrolysis for 30min, then add water to wash to pH 7.0, drain to obtain insoluble dietary fiber;

[0043] (2) Baking the insoluble dietary fiber obtained by the treatment in step (1), the baking temperature is 75° C., and the baking makes the water content of the insoluble dietary fiber to 13.0% to form a modified insoluble dietary fiber for use.

[0044] The preparation method of modified xanthan gum comprises the steps:

[0045] (1) get 12 parts of xanthan gum and add 3 times the volume of water, after stirring and dissolving, be warmed up to 70 ℃, then add 7 parts of maltose, ...

Embodiment 3

[0054] The preparation method of dietary fiber comprises the steps:

[0055] (1) Weigh 20 parts of wheat bran, add 200 parts of water, add mass fraction of 36% acetic acid to adjust the pH between 5.2, soak for 50min; Under the condition of water bath for 50 minutes, filter, add the solid to the same volume of acetic acid solution with a mass fraction of 2% sodium hydroxide for alkaline hydrolysis for 30 minutes, then add water to wash until the pH is 7.0, and drain to obtain insoluble dietary fiber;

[0056] (2) Baking the insoluble dietary fiber obtained in step (1) at a temperature of 70°C to make the water content of the insoluble dietary fiber reach 12.5%, forming a modified insoluble dietary fiber for later use.

[0057] The preparation method of modified xanthan gum comprises the steps:

[0058] (1) Take 8 parts of xanthan gum and add it to 2 times the volume of water, stir to dissolve and heat up to 65°C, then add 6 parts of maltose and 1 part of sodium bicarbonate, m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com