Green and environment-friendly ceramic cutter material and preparation method thereof

A green and environmentally friendly technology for ceramic knives, applied in the field of structural ceramic materials, can solve problems such as endangering workers' health, increasing manufacturing costs, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

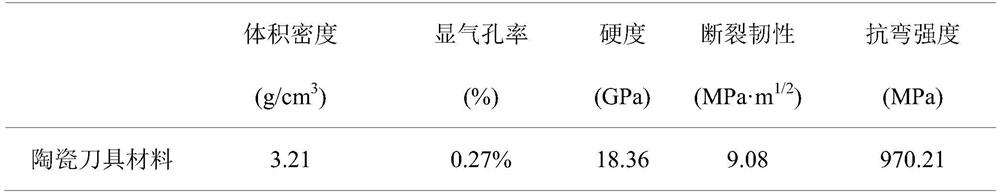

Embodiment 1

[0027] A green and environment-friendly ceramic tool material and a preparation method thereof, comprising the following steps:

[0028] Step S1, the mass ratio of the weighed nano-lignin, silicon nitride powder and magnesium oxide, yttrium oxide mixed powder is 2:88:10, mix evenly and dry to obtain a composite powder; nano-lignin is extracted from poplar, which is green and environmentally friendly. regeneration. And the nano lignin extracted from poplar can be converted into graphene-like materials, forming a coating layer on the surface of silicon nitride grains. When the material breaks, it can passivate the branches, deflection and bridging of the cracks. The bridging of the cracks is formed by the cracking and bridging of the graphene-like film composed of graphene-like materials on the surface after the silicon nitride grains break. Improve material fracture toughness.

[0029] Step S2, after mixing the mixed powder with a small amount of absolute ethanol, ball millin...

Embodiment 2

[0038] A green and environment-friendly ceramic tool material and a preparation method thereof, comprising the following steps:

[0039] Step S1, the mass ratio of the weighed nano-lignin, silicon nitride powder and magnesium oxide, yttrium oxide mixed powder is 4:87:9, mix evenly and dry to obtain a composite powder; nano-lignin is extracted from poplar;

[0040] Step S2, after mixing the mixed powder with a small amount of absolute ethanol, ball milling with a zirconia grinding body to obtain a mixed slurry;

[0041] Step S3, drying the mixed slurry obtained in step S2 with a vacuum drying oven to obtain a composite powder;

[0042] Step S4, grinding the composite powder obtained in step S3, and sieving with an 80-mesh sieve to obtain a composite powder with a suitable particle size;

[0043] Step S5, using a three-dimensional mixer to mix the composite powder obtained in step S4 to obtain a mixed composite powder;

[0044] Step S6, put the composite powder obtained in ste...

Embodiment 3

[0049] A green and environment-friendly ceramic tool material and a preparation method thereof, comprising the following steps:

[0050]In step S1, the mass ratio of the weighed nano-lignin, silicon nitride powder, magnesium oxide, and yttrium oxide mixed powder is 1:89:10, and the mixed powder is uniformly dried to obtain a composite powder; the nano-lignin is extracted from poplar;

[0051] Step S2, after mixing the mixed powder with a small amount of absolute ethanol, ball milling with a zirconia grinding body to obtain a mixed slurry;

[0052] Step S3, drying the mixed slurry obtained in step S2 with a vacuum drying oven to obtain a composite powder;

[0053] Step S4, grinding the composite powder obtained in step S3, and sieving with a 90-mesh sieve to obtain a composite powder with a suitable particle size;

[0054] Step S5, using a three-dimensional mixer to mix the composite powder obtained in step S4 to obtain a mixed composite powder;

[0055] Step S6, put the comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wear rate | aaaaa | aaaaa |

| Wear rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com