Mold cutting roller device with waste discharging function

A die-cutting knife and knife roller technology, which is applied in metal processing and other directions, can solve the problems of chipping, easy accumulation and jamming of waste materials, and affect the integrity of cut products, so as to achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

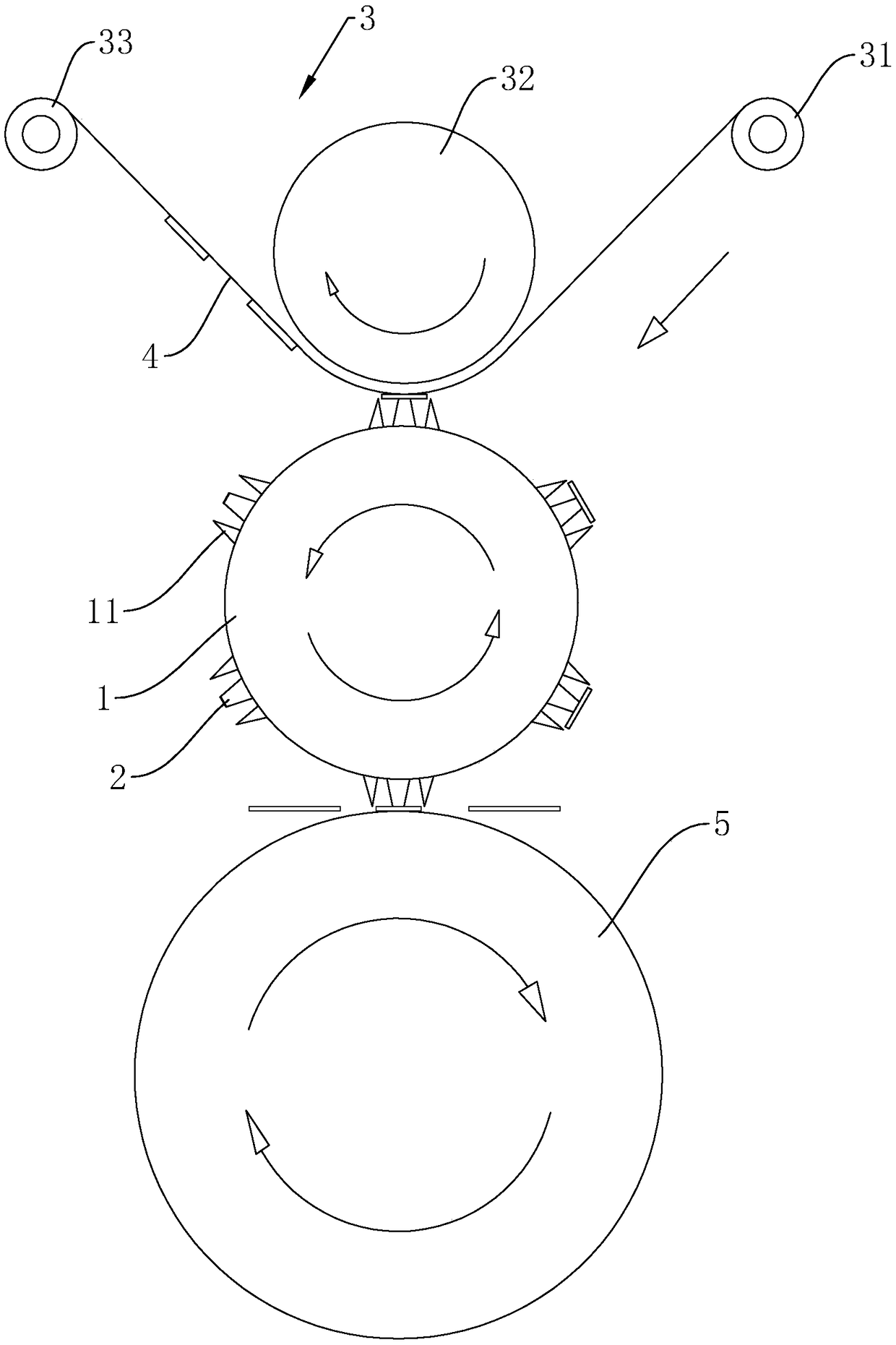

[0033] Such as figure 1 As shown, it is a die-cutting knife roll device with a waste discharge function disclosed in the present invention, which includes a knife roll body 1 and a steel roll 5 . The knife roll body 1 is located directly above the steel roll 5, and the two can be synchronously driven by gears (not shown) mounted on respective shaft ends. Several cutting edges 11 are arranged on the surface of the knife roller body 1, and the cutting edges 11 are milled out and shaped by a milling machine, and the material to be die-cut is sent to the knife roller body 1 and the steel roller 5 through other conveying rollers (not shown in the figure). between, and through the cutting edge 11 for die-cutting. In specific production, the material to be die-cut can be cardboard or PET, PE and other films.

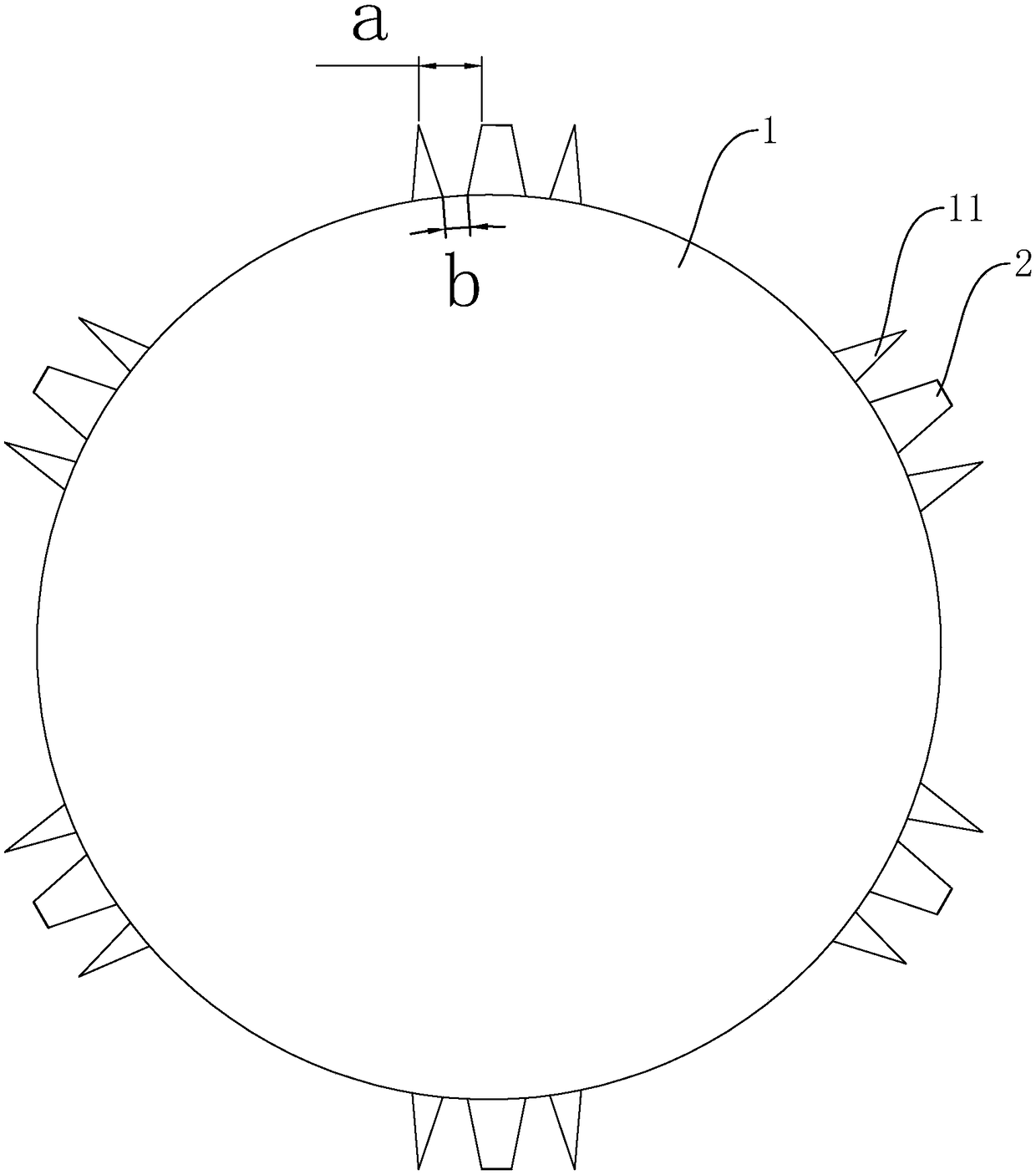

[0034] Such as figure 1 As shown, on the knife roller body 1, a waste lifting block 2 is arranged between two adjacent cutting edges 11, and the end surface of the waste lif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com