Preparation and application of a heteroatom-doped functionalized carbon material

A heteroatom, functionalized technology, applied in the field of preparation of functionalized carbon materials, can solve the problems that carbon materials are difficult to encapsulate with high quality, difficult to form carbon nanocomposites, hinder development and practical application, etc., and achieve excellent methanol resistance. Effects of poisoning performance, good HER catalytic activity, and good industrial application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

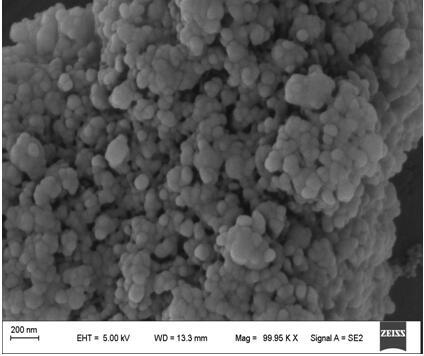

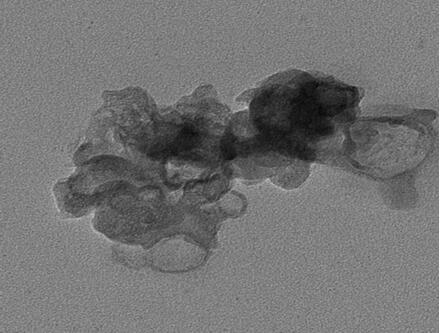

[0039] 1. Catalyst [BMIm][BF 4 ]-700-Co-20% preparation

[0040] a. Preparation of doping material: 1g [BMIm][BF 4 ] and 1 g of silica sol sonicated in 30 mL of 0.07M CoCl 2 In the solution, stir magnetically at 60°C for 12 hours, and dry the product to obtain the doped material product;

[0041] b.[BMIm][BF 4 ] - Preparation of 700-Co-20%: Carbonize the above-mentioned doped material at 700°C for 2 hours in a nitrogen atmosphere, and use HF to remove the template from the obtained carbon material (the carbon material is immersed in HF with a mass percentage of 20% for etching 12h), the product was centrifuged, washed, dried overnight, and ground to obtain [BMIm][BF 4 ] -700-Co-20% carbon material.

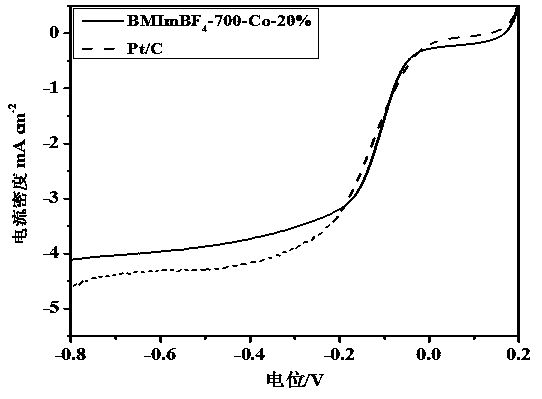

[0042] 2. Oxygen reduction test

[0043] Weigh 5mg [BMIm][BF 4 ] -700-Co-20% Add 0.5mL absolute ethanol and 10μL Nafion (Dupont, 5 wt%) solution, sonicate for 30min, take 3μL and apply it on the glassy carbon electrode. The test was carried out in a three-electrode system....

Embodiment 2

[0047] 1. Catalyst 3 [BMIm][BF 4 ]-700-Co-11% preparation

[0048] a. Preparation of doping material: 1g [BMIm][BF 4 ] and 3g silica sol sonicated in 30mL 0.07MCoCl 2 The solution was magnetically stirred at 60° C. for 12 hours, and the obtained product was dried.

[0049] b. 3[BMIm][BF 4 ]-700-Co-11% preparation: with embodiment 1.

[0050] 2. Oxygen reduction test

[0051] Test condition and method are with embodiment 1, and test result is as Figure 8 shown. Depend on Figure 8 It can be seen that when the rotation speed of the rotating disk electrode is 1600rmp, the scanning rate is 0.01V / s, and the electrolyte is 0.1M KOH, the oxygen reduction onset potential is -0.03V.

[0052] 3. Electrolyzed water hydrogen evolution test

[0053] Test condition and method are with embodiment 1, and test result is as Figure 9 shown. Depend on Figure 9 It can be seen that when the scan rate is 0.01V / s, 0.5MH 2 SO 4 When it is an electrolyte, the electrolytic water hydroge...

Embodiment 3

[0055] 1. Catalyst [BMIm][BF 4 ]-800-Co-20% preparation

[0056] a. Preparation of doping material: Same as Example 1.

[0057] b.[BMIm][BF 4 ] - Preparation of 800-Co-20%: Carbonize the material obtained in the above a above at 800°C for 2 hours in a nitrogen atmosphere, and etch the obtained carbon material with HF (the carbon material is immersed in HF with a mass percentage of 20% for 12 hours. ) to remove the template, the product was centrifuged, washed, dried overnight, and ground to obtain [BMIm][BF 4 ] -800-Co-20% carbon material.

[0058] 2. Oxygen reduction test

[0059] Test condition and method are with embodiment 1, and test result is as Figure 10 shown. Depend on Figure 10 It can be seen that when the rotation speed of the rotating disk electrode is 1600rmp, the scanning rate is 0.01V / s, and the electrolyte is 0.1M KOH, the oxygen reduction onset potential is -0.012V.

[0060] 3. Electrolyzed water hydrogen evolution test

[0061] Test condition and m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com