Method for acidizing and dewatering guanidine nitrate to prepare nitroguanidine in continuous flow micro-channel reactor

A technology of microchannel reactor and channel reactor, which is applied in the fields of chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of bulky reaction kettle, occupying a large factory building, and high temperature control requirements, so as to avoid Severely corroded equipment, reduced generation of waste acid, and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

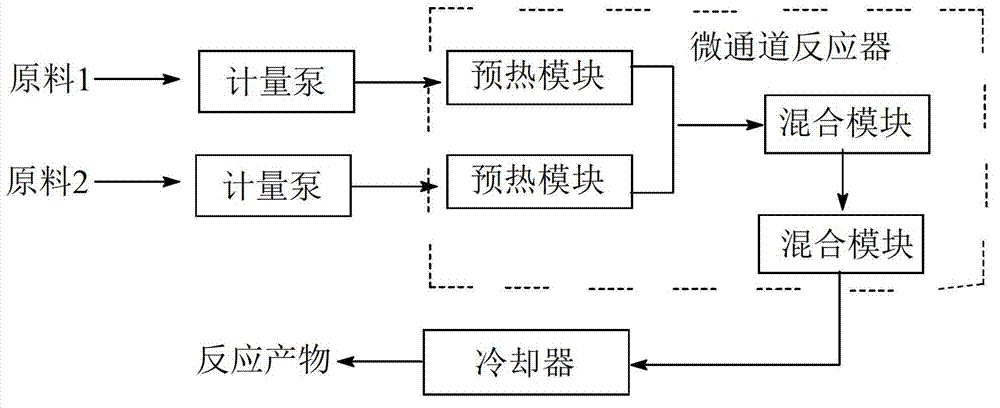

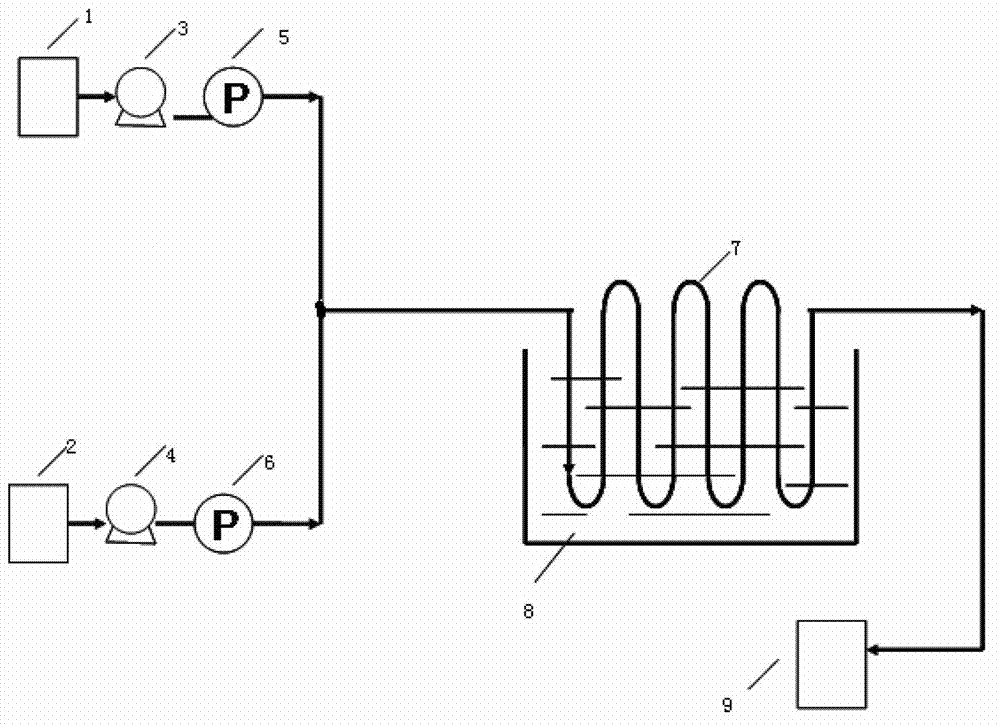

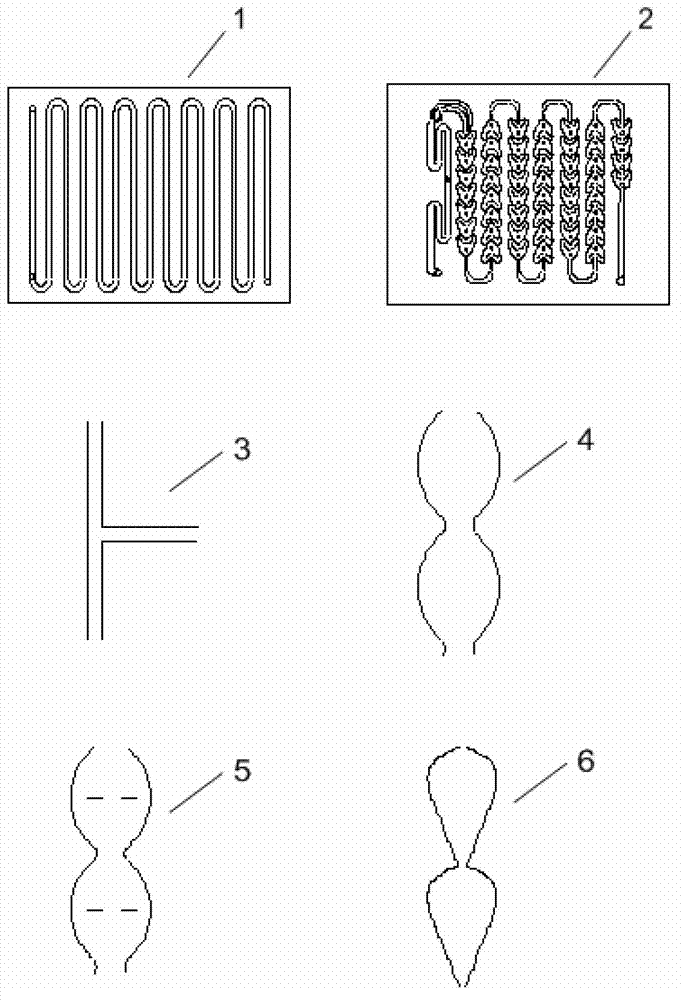

[0043] (1) Device used: continuous flow microchannel reactor (straight channel functional module + "heart-shaped" structural functional module), refer to image 3 Determine the connection mode of the microchannel reactor, the number of mixed reaction modules is determined according to the flow rate and reaction residence time, and the heat transfer medium is heat transfer oil.

[0044](2) Raw material tanks 1 and 2 are equipped with 10% guanidine nitrate aqueous solution and concentrated sulfuric acid. Set the flow control of each metering pump 3 and pump 4 to change the guanidine nitrate aqueous solution: concentrated sulfuric acid molar ratio = 1:0.9, control the flow rate of the guanidine nitrate aqueous solution: 0.25mL / min, control the concentrated sulfuric acid flow rate: 0.2mL / min, and separate the materials Pour into each straight channel preheating module, and control the reaction temperature to be 40°C; the guanidine nitrate aqueous solution and the concentrated sulf...

Embodiment 2

[0047] (1) Device used: continuous flow microchannel reactor (straight channel functional module + droplet channel), refer to image 3 Determine the connection mode of the microchannel reactor, the number of mixed reaction modules is determined according to the flow rate and reaction residence time, and the heat transfer medium is heat transfer oil.

[0048] (2) Raw material tanks 1 and 2 are equipped with 15% guanidine nitrate aqueous solution and concentrated sulfuric acid. Set the flow control of each metering pump 3 and pump 4 to change the guanidine nitrate aqueous solution: concentrated sulfuric acid molar ratio = 1:1, control the flow rate of the guanidine nitrate aqueous solution: 0.2mL / min, control the concentrated sulfuric acid flow rate: 0.2mL / min, and separate the materials Pour into each straight channel preheating module, and control the reaction temperature at 50°C; the guanidine nitrate aqueous solution and the concentrated sulfuric acid are respectively inject...

Embodiment 3

[0051] (1) The device used: continuous flow microchannel reactor (straight channel functional module + spherical baffle plate channel), refer to image 3 Determine the connection mode of the microchannel reactor, the number of mixed reaction modules is determined according to the flow rate and reaction residence time, and the heat transfer medium is heat transfer oil.

[0052] (2) Raw material tanks 1 and 2 are equipped with 40% guanidine nitrate aqueous solution and concentrated sulfuric acid. Set the flow control of each metering pump 3, pump 4 to change the aqueous solution of guanidine nitrate: concentrated sulfuric acid mol ratio=1:2, control the aqueous solution flow rate of guanidine nitrate: 0.2mL / min, control the concentrated sulfuric acid flow rate: 0.8mL / min, the The materials are injected into the preheating modules of each straight channel respectively, and the reaction temperature is controlled to be 90°C; the aqueous solution of concentrated guanidine sulfate an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com